Hi Jon ,

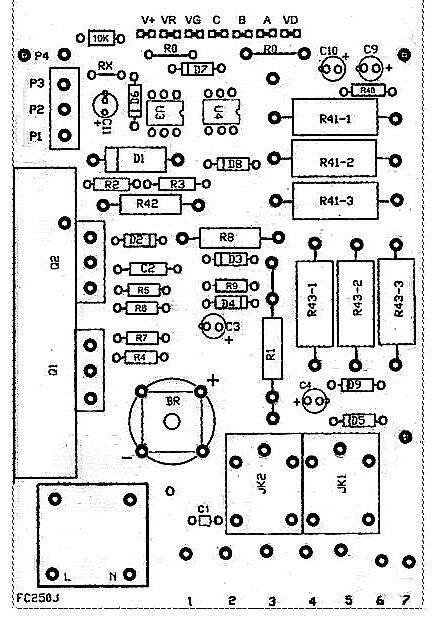

I assume your board looks like this

the two yellow relays on the left , near the terminals

form part of the interlock circuit that forces you to start at minimum speed

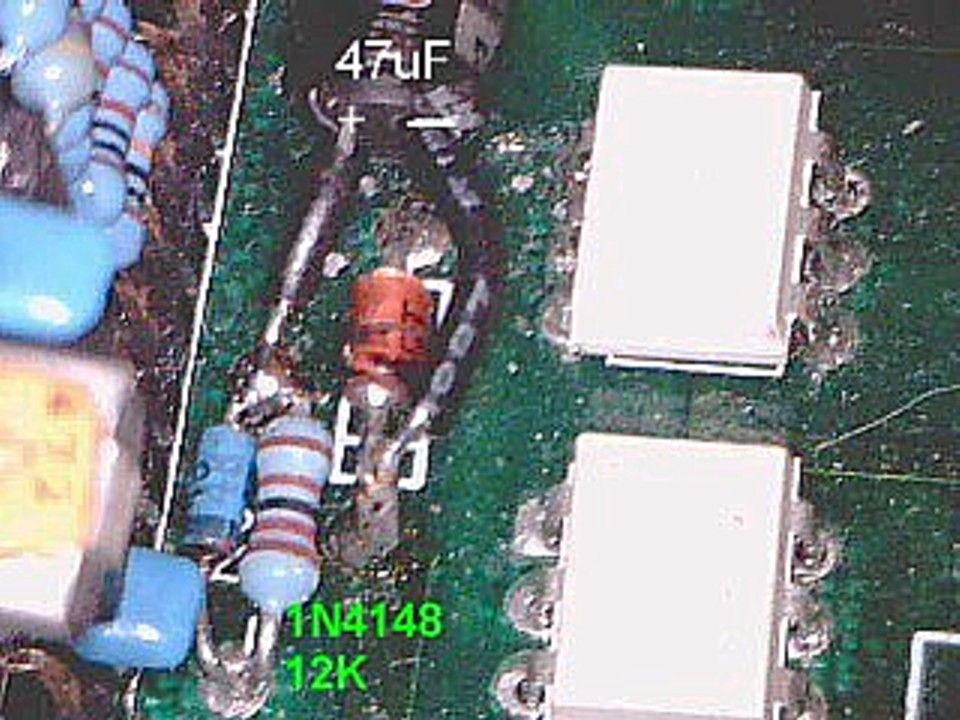

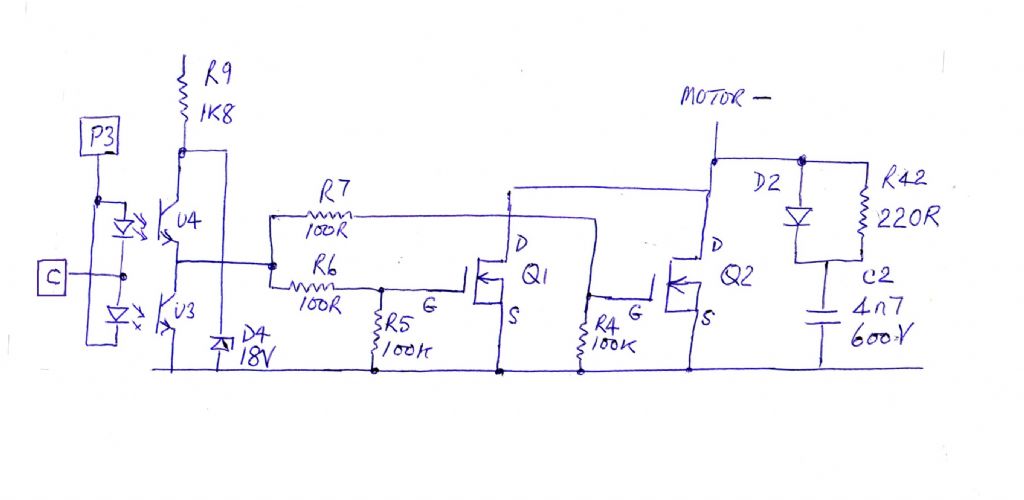

one of the common faults is the two FET’s ( on the heatsink on the right )

go short circuit and the motor runs at full speed

with the mains supply disconnected

if you measure the resistance between the gate and source terminals on each FET

you should be 50k (50,000 ohms)(outer 2 terminals)

between the drain and source should be virtually open circuit –

more than 20 M ohm (20,000,000 ohms)

even with a faulty speed control potemtiometer ,

the maximum speed in reverse should be about half the forward speed

the speed control is special 5k linear potentiometer plus a single pole switch

that you have to buy form the likes of machine mart , arc euro trading etc.

while it looks like the on/off and volume control on a radio

the potentiometer is linear not logarithmic and the switch is closed when fully anticlock wise

not open !

a new board from machinemart will be quick , but expensive

if in stock arc euro trade for example will be less expensive

if you decide to replace the FET’s your self

you can use two 2SK790 , IRFP450 or STW20NK50Z FET’s

either from RS components . Rapid online etc or ebay

John

Edited By john swift 1 on 03/02/2011 00:05:55

jacek nowak.