Hi Bill ,

the motor cover is held by the same type of screws as the rear splash guard – M5 x 8 pan head

the screws attaching the pcb as far as i can tell are

no 4 self tapping screws 3mm dia x 6.5mm

the 4 for the pcb cover are no5 self tapping screws 3.7mm dia x 8mm

i’ve not found any supplier for small quantities (10)

try Machinemart first

( chipboard screws are the nearest but with counter sink heads

add a washer to protect the pcb

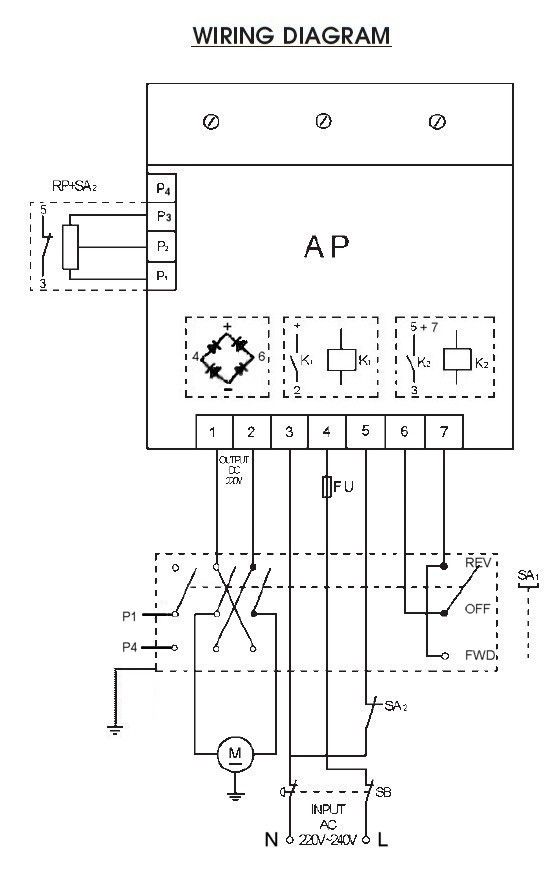

the mains cable is 3 core 6A ~ 6.5 mm dia

most of the wiring can be

Maplin black 6A equipment wire KR31J 24/0.2

use eyelet JH62S for connections to earth on the headstock

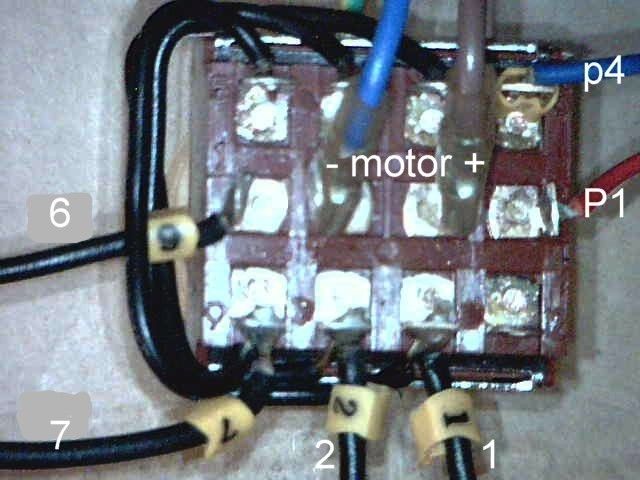

spade JH64U for pcb terminals 1 to 7

lucar f/m HF10L for connection to the emergency stop

lucar boot FE65V for 1/4″ connector HF10L

fuse holder boot FT35Q extra insulation not on original

just ensure the LIVE connection is to REAR terminal and not the side terminal

( if you remove a good fuse with the power on , you could get a shock if

you have it the wrong way round )

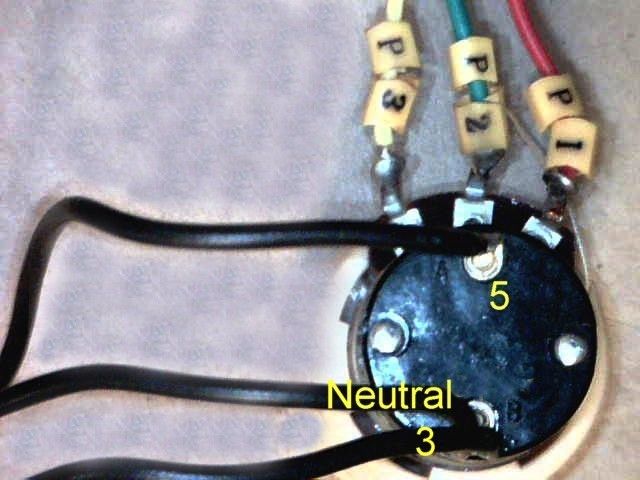

wires P1 to P4 can be connected with wire like 3A equipment FA36P 16/0.2

the motor wires have as smaller f/m lucar terminal to fit the terminals

on the forward /reverse switch – 4.8mm N35CY

add cable markers to make it easy to identifiy the cables

if you don’t have one

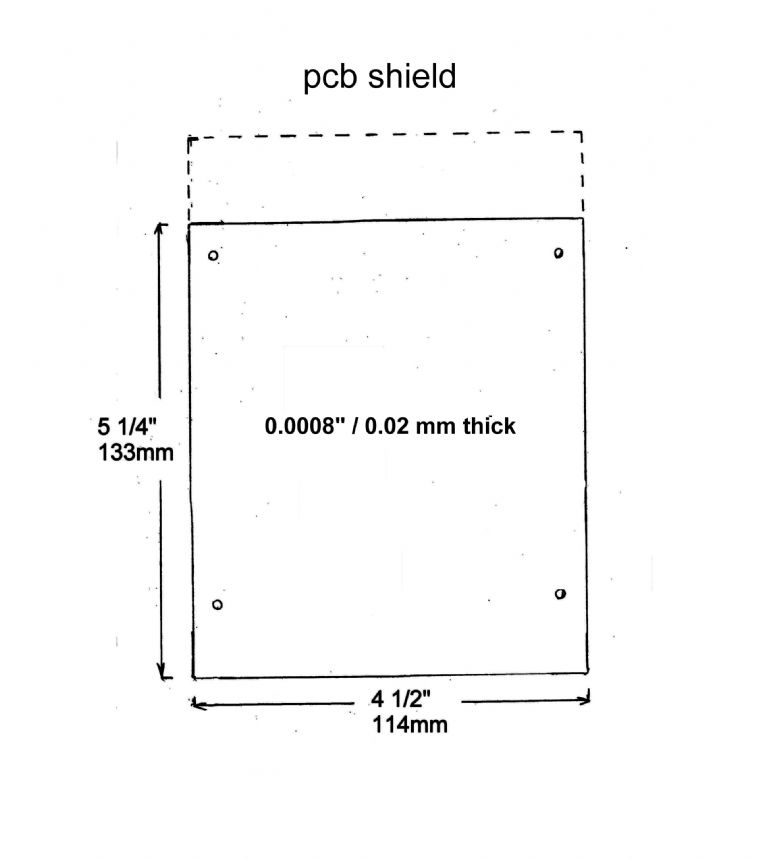

the plastic cover for the pcb is 133mm x 114 mm , 0.2 mm thick

i made an extra one , about 25mm longer , with the extra bit bent at right angle to

make contact with the headstock

hope this helps

John

Edited By john swift 1 on 03/12/2010 00:20:31

Edited By john swift 1 on 03/12/2010 00:21:52

jacek nowak.

(sigh of relief). I do not have any of the component you suggested only what you can see on the earlier picture. Will I need to order these?

(sigh of relief). I do not have any of the component you suggested only what you can see on the earlier picture. Will I need to order these?