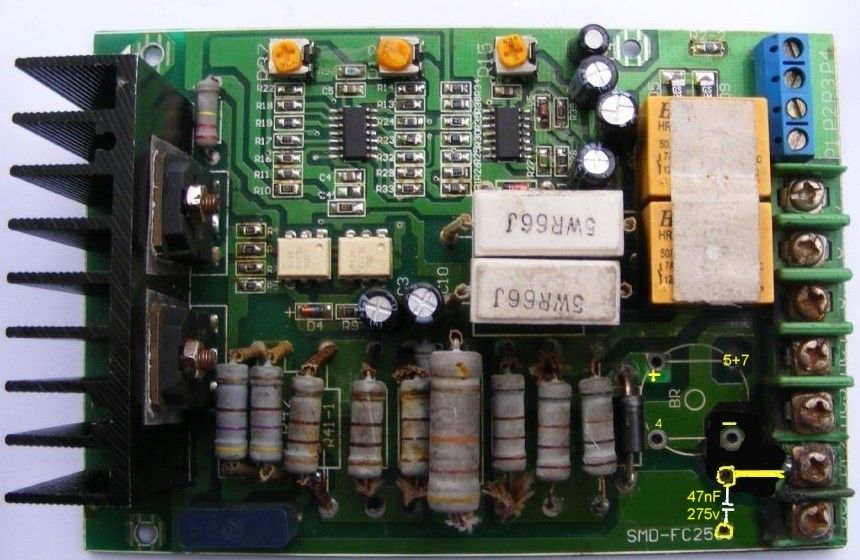

speed control pcb for Clarke CL300 lathe

speed control pcb for Clarke CL300 lathe

- This topic has 225 replies, 48 voices, and was last updated 15 June 2022 at 19:06 by

jacek nowak.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- “swedish iron”

- TurboCAD – Alibre File Transfers.

- Another Day … Another ScumBag

- Sat nag

- buying machine tools from aliexpress experiences?

- Adjustable spanner thread direction

- Chester Champion, warco ZX15 drawbar

- Bosch PBD 40 bearing upgrade

- Square end on round stock – Milling?

- motor and switch wiring Myford ML7

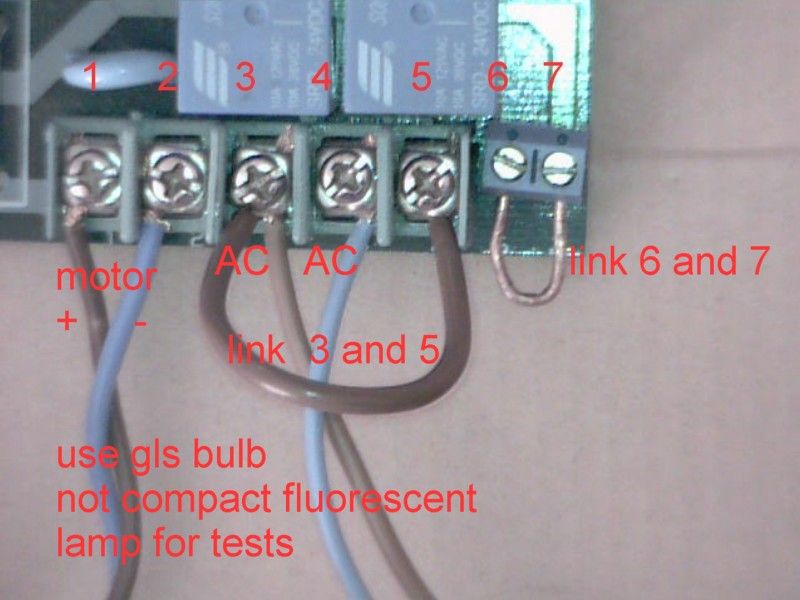

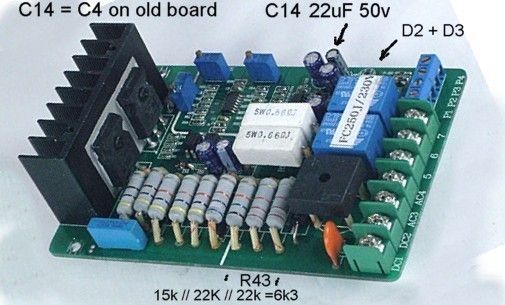

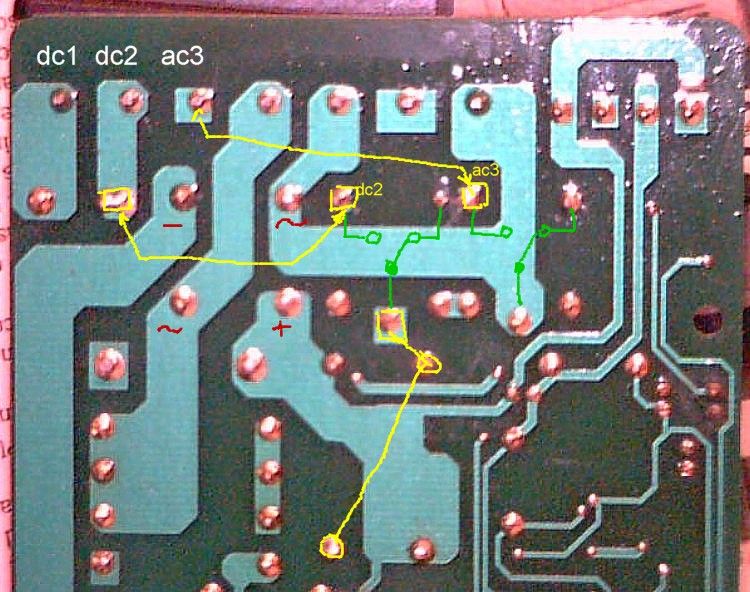

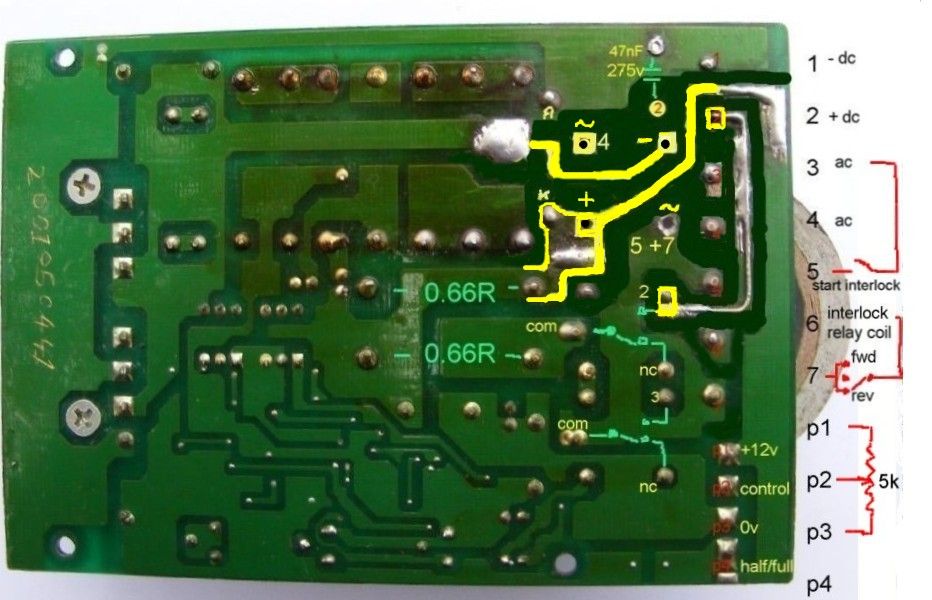

but did not blow the bridge rectifier or the motor’ I have had the motor tested by my nephew who works for a rewind company and it’s OK’ and I have sort off figured out the component side of the CB there is a bit of L shaped tracking missing between DC2 and the rectifier leg’ also there is a capacitor next door to the rectifier; do you know it’s value?. I have repaired the hole since the photos John don’t know whats gone wrong with photos they seem to have got lost must have done something wrong? they only place they show up is in albums?

but did not blow the bridge rectifier or the motor’ I have had the motor tested by my nephew who works for a rewind company and it’s OK’ and I have sort off figured out the component side of the CB there is a bit of L shaped tracking missing between DC2 and the rectifier leg’ also there is a capacitor next door to the rectifier; do you know it’s value?. I have repaired the hole since the photos John don’t know whats gone wrong with photos they seem to have got lost must have done something wrong? they only place they show up is in albums?

What I could do with is some kind soul to do me a walk through on how to post PHOTOS’ as I am fairly new to computers. MANY THANKS AGAIN FOR THE TIME YOU MUST HAVE TAKEN’ REGARDS Bob.

What I could do with is some kind soul to do me a walk through on how to post PHOTOS’ as I am fairly new to computers. MANY THANKS AGAIN FOR THE TIME YOU MUST HAVE TAKEN’ REGARDS Bob.