Merry Christmas and a happy New Year everyone.

Merry Christmas and a happy New Year everyone.

My planned Christmas present from Mrs B was delayed, but fortunately an item I happened to see on Ebay turned up just in time to replace it.

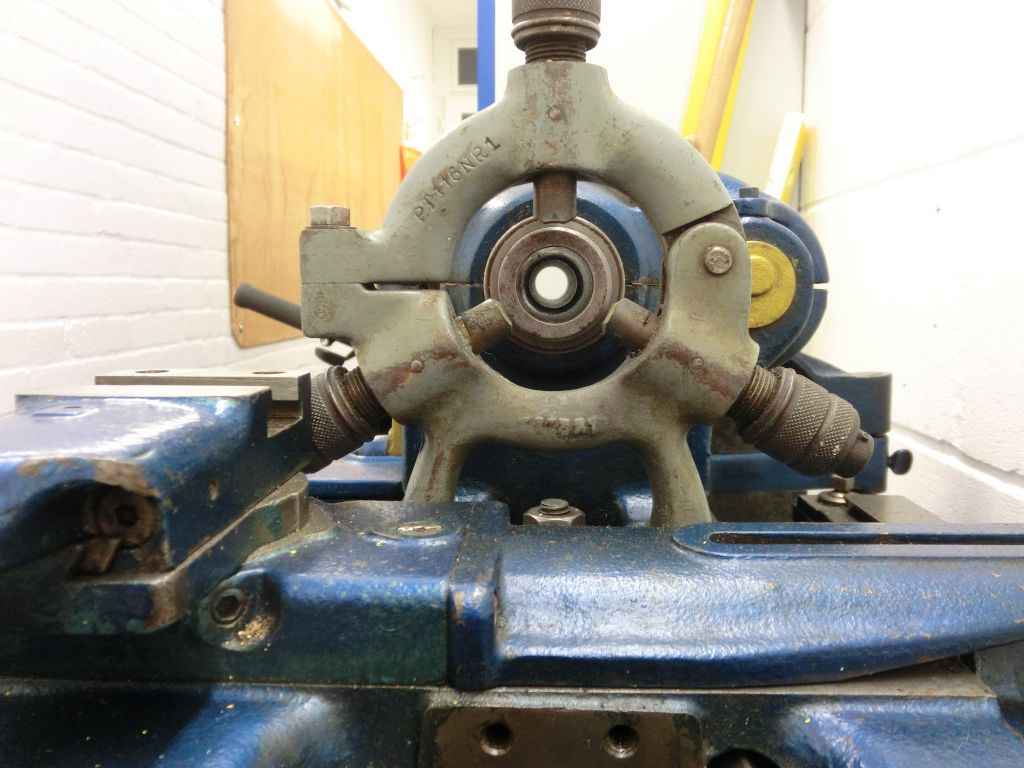

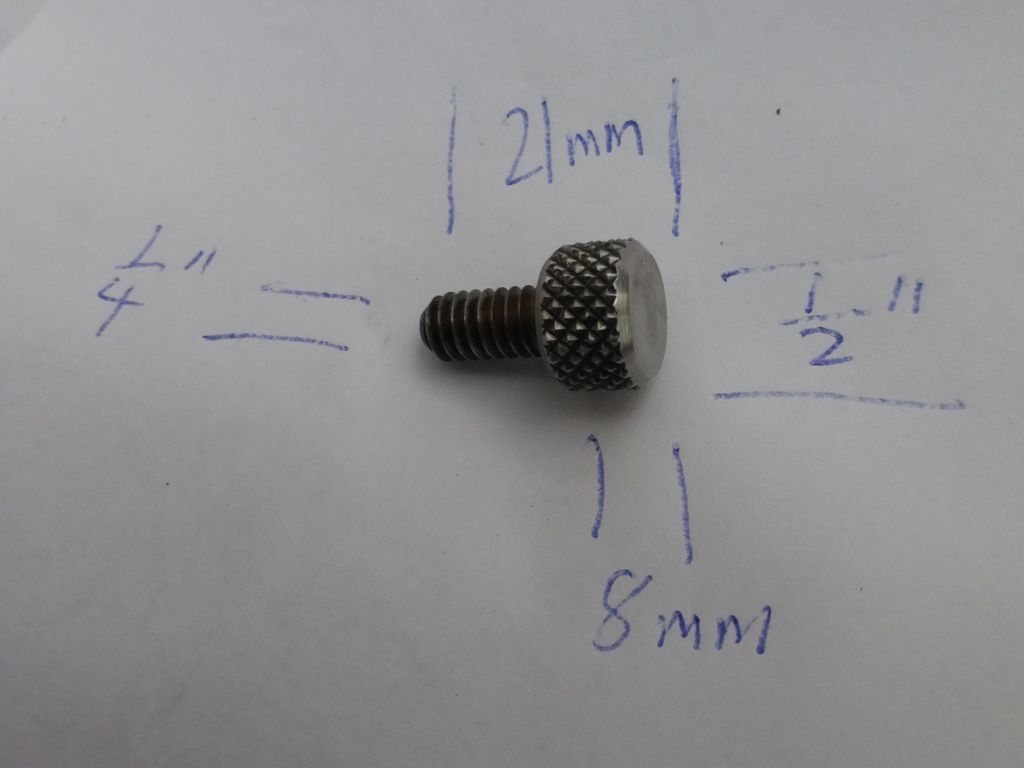

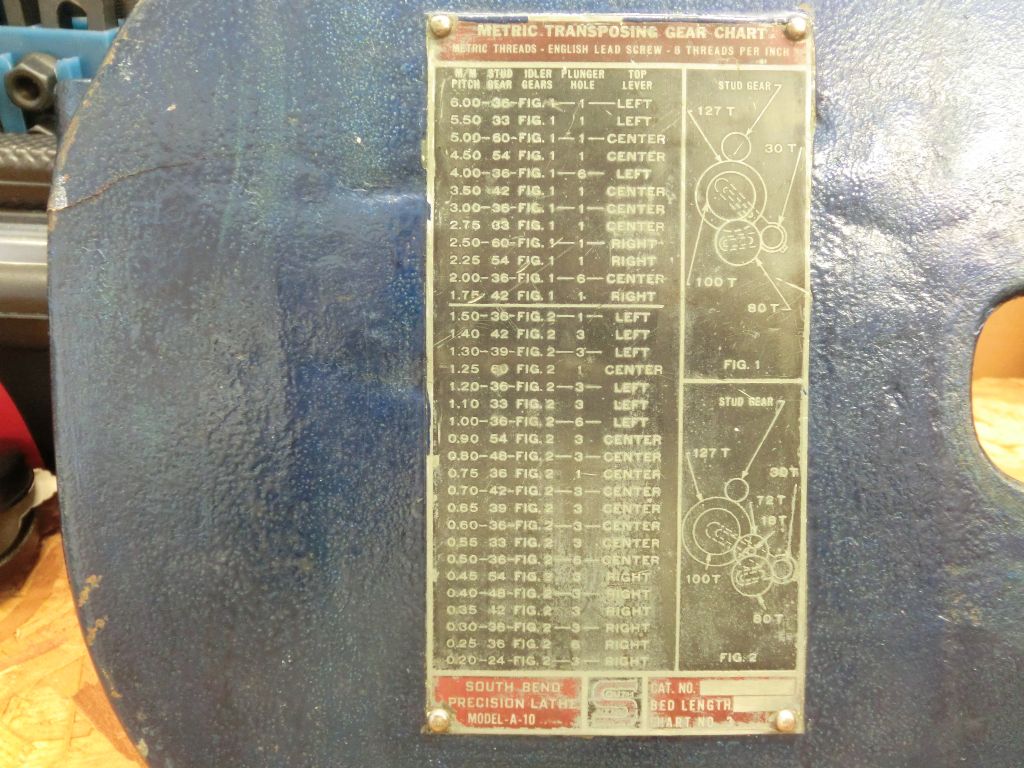

A fixed steady for the South Bend lathe. This is a very rare item in the UK, where these lathes are uncommon to say the least, and an expensive import so this one was worth a punt. In the event this item not only fits perfectly but also works perfectly as well, so I am very pleased. The only point of note is that two of the knurled locking screws have been replaced with brass slotted grub screws, this has happened recently as the screws are bright; I would have thought that they are a bit easy to damage, so I shall seek or make replacements.

This should allow me to machine long shafts and tubes, especially some steel I have that will be good for wheels and rolls for the small traction engines and rollers that I like, I am still crossing my fingers as the diameter that this fitting allows is a bit small. That's what you get with a tool room lathe that assumes that there is a bigger lathe somewhere. The upside is that this casting is very strong and flows metal around the adjusters, which are sublime in action, so it is many times better than the current style of inexpensive lathes that have most of the metal slotted out. Either way this important piece of kit was missing from my machine so it is now complete in that I have a travelling steady, three and four jaw chucks and a taper turning attachment.

Allowing for the chuck I should be able to cope with 500mm long workpieces.

Roger Best.