On the LUXdrive units (they look nice!) I couldn't see a Vout on the site Michael linked to (may have missed something?) but the LUXdrive A011-D-V-700 is available in the UK from Digi-Key for £20.50 and they give a maximum Vout of 48V – so they should be fine for this application.

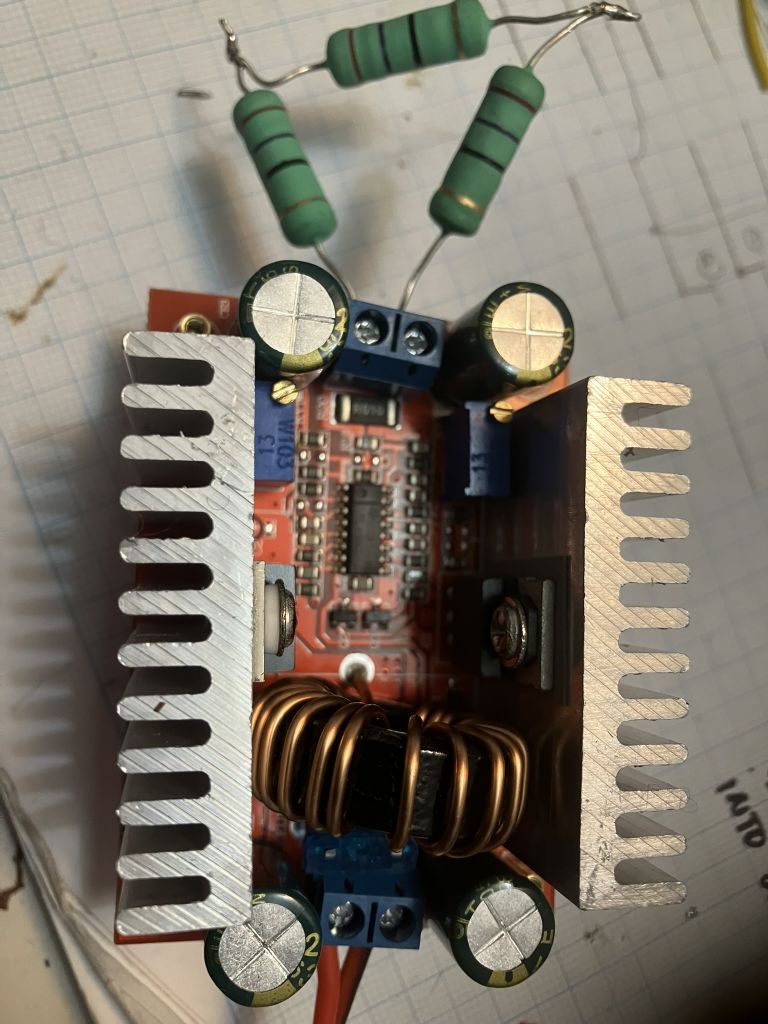

On other (cheaper) solutions I, like Noel, ordered a 400W booster (£8.49):

Reading Les' account I went very carefully! With 10V input and no load I adjusted the output to 12.5V – the module drew ~10mA. Connecting an 81 ohm load (shown) the voltage remained stable and it drew 220mA at the input . Cranking the current pot right down the voltage across the load dropped to 11.5V, so I guess it's working as expected and I'm hopeful that it will be OK to drive the LED array..

A slightly odd thing is that the +ve output appears on the leftmost heatsink in the photo. Something to be aware of if going down this road.

Robin.

Edited By Robin Graham on 26/01/2023 21:40:12

Edited By Robin Graham on 26/01/2023 21:42:35

Edited By Robin Graham on 26/01/2023 21:43:21

Edited By Robin Graham on 26/01/2023 21:57:24

Mark Easingwood.

Mark Easingwood.