Solid Edge Community Edn. – Gen. Qs. Thereof

Solid Edge Community Edn. – Gen. Qs. Thereof

Home › Forums › CAD – Technical drawing & design › Solid Edge Community Edn. – Gen. Qs. Thereof

- This topic has 101 replies, 19 voices, and was last updated 6 March 2022 at 01:16 by

Nigel Graham 2.

-

AuthorPosts

-

26 December 2021 at 07:11 #576798

JasonBModerator@jasonbPosted by Nigel Graham 2 on 25/12/2021 22:28:30:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 25/12/2021 22:28:30:…. Why on Earth has copying it thrown the rendering away – neither intended, nor previously met?

Depends how you copied it but I suspect when you clicked on it you in effect only clicked a layer and that is what was copied.

You may want to look at the thread about Kant Clamps, I posted a good example of why being able to animate an assembly is so useful

26 December 2021 at 07:49 #576800 Gary WoodingParticipant@garywooding25363Posted by Nigel Graham 2 on 25/12/2021 22:28:30:

Gary WoodingParticipant@garywooding25363Posted by Nigel Graham 2 on 25/12/2021 22:28:30:Thank you very much, Gary, for your very generous offer; but as you dojn't have a public profile, it tells me, I cannot see how to send you a PM!

That's very strange, I've received several PMs in the past.

26 December 2021 at 08:07 #576804 Gary WoodingParticipant@garywooding2536326 December 2021 at 13:42 #576845

Gary WoodingParticipant@garywooding2536326 December 2021 at 13:42 #576845Nigel Graham 2

Participant@nigelgraham2Peter –

Thank you for pointing that out. Will do!

Jason –

Layers. Ah. Could be. I have just opened the drawing, and find it does use layers: 1 for the centre-lines (which did not copy), 2,3, and 4 for the parts, but only for contrasting colours; and they all render as I intended in the Model Space.

I copied it as seems the proper way. I have just tried again, noting what commands to use, and what they each do in turn:

– Create a "View" of the model image, within a selection frame the tool starts.

– Move to Paper Space, Insert "Viewport"; [Go to] the selected View; and it shows it. Select [Close] to plant it on the "paper" for printing.

The rendering is removed from all three layers somewhere between the View selection and the [Go To] stage, before the [Close] that effectively means "Paste"..

Gary –

Thank you. Will message.

26 December 2021 at 14:06 #576849 Gary WoodingParticipant@garywooding25363

Gary WoodingParticipant@garywooding25363Nigel: Select the viewport, right click and select Properties, then choose the layers to be included.

26 December 2021 at 18:45 #576889Nigel Graham 2

Participant@nigelgraham2Gary –

My version of TC does not let you do that.

I found a Layers command and values display table, but it is not a control, just a statement of facts. So I analysed them by going back to the layer setting-form, instead, and selectively closing the little eyes ( Options -> Layers.)

This confirmed the pump components are on 4 layers, including the reserved 0 I used in fact, plus Layer 2, which by chance is the one I set for the centre-lines in this particular drawing. Usually I try to use L1 and L2 for the centre-lines and dimensions.

Those layers are : –

0) Black: Supposedly reserved, but I found I have used it for the end seals (thin washers)

1) Dark olive-goo: the casting and valve-body (with the T-drillings, held to the front end by one of the union nuts),

2) Black: centre-lines – I seem to have set the layer but have omitted the lines.

3) Dull "brass" yellow: the 2 used and 1 spare nuts

4) Grey: ram, links and lever – I noticed I have made the lever itself dark green.

The View is clearly picking up all 5 layers, as all 4 populated ones are visible. If it did not, I'd think it would show only certain parts, like the ram and links, floating in space.

What I did notice about that layers characteristics (not setting) table is that it lists render types, but shows all on each very crowded layer-line. I have no idea what this table is really telling me.

So it remains a mystery. It's bad enough me unable to control the printing sizes and scales properly, without TC itself now playing strange tricks. I'll see if this happens on another attempted 3D drawing. .If it does not, it might mean I have embedded some unknown, untraceable fault in that tender-pump drawing….

…. A far simpler thing based on a partially-complete exercise on Paul Tracy's tutorial. The object to be drawn is a simple padlock, and on my exercise is just a rectangular block with half a toroid ('Swept' circle) on top, in two different colours of which neither match the Layers form. No: it behaved in the just the same way.

'

Oddly the padlocks' layers include one called "$Constraints", tinged green. Was that in the instructions?

When I started to trying to learn the programme I did not use only the tutorial. I also invented very simple exercises such as blocks with holes through them, painstakingly assembled by calculating their entities' co-ordinate changes. So I revisited one such.

This too has a "$Constraints" layer… and also fails to render and copy properly. Since I have no idea what 'Constraints' are, in any currency, I would not have made any such layer, and have no idea how and why they formed.

Edited By Nigel Graham 2 on 26/12/2021 19:14:54

26 December 2021 at 21:16 #576903Nick Wheeler

Participant@nickwheelerThose are just some of the frustrations I had with Turbo Cad. I wasted more hours than I want to think about over several years, not to mention buying(and upgrading) the program in the first place. In all that time I never managed to create a useful model. Swapping to a native 3D program was a breath of fresh air; layers, paper space, view ports, complex work planes all became unnecessary, and a simple part was on the screen by the end of the evening.

here is your lock:

the hoop and two sketches to create it

and with the joint open plus the single sketch for the body created by two simple extrusions

Finishes are stock brass and stainless steel materials, and Fusion suggests it will weigh 261g

I spent more time saving and uploading the JPEGs than I did creating the model….

26 December 2021 at 22:52 #576905Nigel Graham 2

Participant@nigelgraham2I am impressed! Obviously I realise your speed at drawing is thanks to considerable experience and skill. I can't help thinking there is a lot more to it than that, though, and especially if you also want accurately dimensioned, scaled, printed elevations for the workshop.

Is a "native 3D program" as you call it, one working only 3D-first? If so, it must be possible to extract from the 3D model, orthogonal drawings for the workshop? It would be no use without!

I thought "layers" are basic to all CAD and photo-editing programmes, and the two generic CAD primers I have discuss them. For: defining line properties; repeating assemblies; construction by the CAD equivalent of the manual technique of laying one drawing on tracing-film over another. So do Fusion and similar have layers but under a different name, or do they use a very different method; but still to the same ends?

Fusion et al might not call them "work-planes", but you still need select the next operating facet of the 3D object; so isn't it just a rose by any other name?

Paper space and viewports are "only" TurboCAD's way to copy part of a potentially very wide Model Space region, to a standard sheet of paper at the wanted scale. (If you know how.) All CAD programmes must do something equivalent, so do others essentially use effectively a combined "Model + Paper Space", and call the scale and printer settings into that?

Your lock shows something common to most CAD examples here and in the magazines: joint-lines between the drawing's objects. Is that simply by default, primary rendering? TurboCAD also allows Adding them, e.g. to make that staple one piece. (You can't separate them again, except as an editing "Undo".) Do Fusion etc allow that?

27 December 2021 at 07:13 #576913 JasonBModerator@jasonb

JasonBModerator@jasonbLike Nicholas, I never have anything to do with layers and all these various spaces you mention just simple 2D sketches extruded to give the third dimension. If you look closely at his images you can see the white "outlines" of these 2D sketches that were then extruded as solids or cuts or in the case of the hasp swept or rotated.

It is very simple to produce 2D working drawings from those 3D models that can be scaled to fit the size of paper you want to use, even possible if you have some smaller components to have them at a larger scale to bigger bits on the same sheet or magnified detail areas at a larger scale.

By "joint lines" do you mean for example where the straight part of the staple transitions to the bent part, if so yes that can be turned on or off, It is not actually a joint just a change in direction of the surface from parallel to curved as it was formed as one swept part. The only "joint is where the bent bit meets the pivot but a fillet could have been added there and then it would all flow as one.

27 December 2021 at 09:42 #576924Nick Wheeler

Participant@nickwheelerNigel in order:

the speed – effectiveness is a better word – of drawing is mostly being able to recognise the most suitable profile to start with. Anyone who can make a 2D drawing of a 3D object should have a head start with this. I find it odd that it's this bit that seems to cause the most problems.

Native 3D – it has to start with a basic 2D outline, but that's converted to 3D as soon as possible. Fusion even calls these outlines 'sketches' which should give an idea of what is needed.

Layers are needed in 2D CAD due to all the extra stuff needed to represent 3D objects: hidden faces, construction lines, through holes, different colours, cross sections, matching parts, etc etc. The 3D equivalents would be sketches for additional features and the extrudes/sweeps/revolves to make them, and you should label each of those as you go along, but you don't need to be able to turn on/off the visibility of each operation once it's completed.

Yes, Fusion still needs 'work planes' but it makes far less fuss about how they're created and used: if you want a slot across a face, you draw its outline directly on that face. Additional planes are easily created at angles, through 3 points, along a line which was how the hoop was done, centred in an object(which is very useful) and so on.

You create the model fullsize. The program sorts out the scale necessary to fit your intended 2D drawing's elevations and other images onto whatever paper size you've selected. Doing that yourself would be like buying and training a rotweiler, but chasing off an intruder on your hands and knees while barking yourself hoarse. I haven't done much with the workshop drawing part of this, because most of my parts can be done with dimensions on the the 3D model for less effort.

Joint lines. Yes they're visible. Who cares? Time spent on rendering for a pretty picture for a customer gets rid of them, but why bother when you're the customer and the whole point is to design and make physical parts that will work as intended?

3D CAD removes the need for all the hard work 2D drawing creates: extra lines, layouts, scales, maths(who wants to keep working out how to make a line tangent to a random curve?), coordinates and so on. Then there's all the other essential things that are hard to do on paper but are basically free in 3D: cross sections at any place, mating parts made in place – pistons in their bores, fixtures or jigs – assembly clearances so you can actually get the bolts in, exploded diagrams, parts lists, part weights and centre of gravity, range of motion and many others.

It's those extras that make learning a 3D program worth the effort. It's not as if we all knew the basics of technical drawing after three 45minute lessons as 13 year olds. Some of the class I was in were still calling set squares 'rulers'……

28 December 2021 at 00:28 #577050Nigel Graham 2

Participant@nigelgraham2Thank you…

As reminder, my original question was not to find if one CAD package is intrinsically "better" than another; but which might subjectively be better for me.

I leave the competition to users' personal preferences based on their technical need and far greater CAD skill than mine.

Obviously these things all do the same task, and probably in much the same ways internally.

So I do not hold any one high-grade system inferior or superior to its rivals. I see all these professional-level packages as differing considerably in screen appearance and controls, and in ranges of functions offered; but all of similar quality and flexibility.

The weaknesses are not in these programmes, but in me.

So I am trying to assess which of TurboCAD or SolidEdge (Community) may be the easier for me to learn to a practicable level in both 2D and 3D.

– It may be better I stay with TC and try to improve my shaky skill in that; because changing means starting all over again with a different-looking programme with different tools.

– Or I switch to SE if it may be simpler for me to learn and use to a higher level.

– With the same aim in both: both isometric assembly and orthogonal machine-shop drawings of an adequate standard I can use.

(Oh, before anyone else tells me off about the terms, TC does call its projections 'isometric' and 'orthogonal'!)

'

Jason –

I did see the white source outlines and realise their meaning, yes.

Layers and "spaces" are a different aspect, but TurboCAD offers a library of editable "primitive" 3D shapes and constructions, as well as its Extrude, Sweep, Revolve, etc. tools. So more than one way to create a 3D form.

'

Nicholas –

Efficiency: I see your point, but consider recognition is as much part of the skill as being able to drive the programme, and comes with experience. Skill and experience are not synonyms; it is possible to be strong on one but weak on the other.

'

'Sketch': I recall the term from trying Fusion, but did not really appreciate what it meant.

'

Layers: I find them a natural and very valuable tool, but understand other CAD programmes may not use them. I would not put holes on a different layer to the rest of the item though, regarding them as part of it.

In TC, construction-lines are automatically on a discreet layer. More often I produce a drawing line across the two adjoining elevations, then trim it to suit both.

One particularly valuable use of Layers is setting the component you are drawing in its assembly context. For example, to help me re-designing my engine's cylinders, I drew the covers on the block in plan, but on their own Layer in a contrasting colour. So having copied the stud-holes in place as part of the main Layer (the block's), I can slide the covers out of the way or back on, but keep them on the same "Model Space" for their own drawing.

I daresay other CAD packages have their own means to that end; but do not see Layers as "wrong" just because I found them awkward to learn. (I thought TC's 'Group' tool fulfills a slightly similar role, to allow copying assemblies within and between drawings, but I may be wrong.)

'

Scale: I realise the drawing itself is "full-size" by the screen rules, co-ordinates etc. TurboCAD allows you to transfer the image to the required scale to right-size paper on the printer – but it is I who cannot make it do that properly.

There is nothing wrong with the programme, just its user!

'

"… the hard work 2D drawing creates …" It is all hard work: as much effort in 3D drawing as 2D – if not more.

The programme does not force the user to do its mathematics for it, and I did not accuse it of that.

I had to calculate co-ordinates etc. only because I could not understand how to assemble the separate entities into a cohesive isometric drawing.

Again, nothing wrong with the programme, just its user!

'

Ancillaries: Clearances around bolts etc., should be revealed in either 2D or 3D, manually or by CAD.

I cannot see how drawing a piston in a cylinder is any easier in 3D than 2D projection, in CAD. Orthograpically they are circles and rectangles; isometrically, elliptical cylinders. Although the software plots them, you still need "tell" it where to plot them respectively to each other; and I find 3D the much harder mode.

By assessing range of motion, do you mean by animating a 3D drawing? I could not reach those heights.

I would leave weights, c.g. and the like to industry. Though I have 'Excel' for parts-lists if necessary, if I could not count a dozen components, I could not make them in the first place.

I still have to design the thing, however I draw it.

If the method of drawing it helps me design it so much the better, but I still need learn to draw it; and I know that CAD represents a massive skills overhead on knowing how to design and make the thing itself.

28 December 2021 at 01:52 #577053Anonymous

Posted by Nigel Graham 2 on 28/12/2021 00:28:21:I cannot see how drawing a piston in a cylinder is any easier in 3D than 2D projection, in CAD. Orthograpically they are circles and rectangles; isometrically, elliptical cylinders. Although the software plots them, you still need "tell" it where to plot them respectively to each other; and I find 3D the much harder mode.

Exactly what I meant when I said earlier:

"Prior exposure to 2D CAD is probably more of a liability than a help. "

28 December 2021 at 07:14 #577062Steve Pavey

Participant@stevepavey65865The learning process with any software is an interesting topic. My working life has included standing at a drawing board, and much later on teaching various software applications including Photoshop and Illustrator, to both adults and children. Teaching adults is a nightmare – they usually bring with them a lifetime of baggage, and their objections and observations all seem to consist of phrases like ‘why doesn’t it draw this/ that way’, or ‘why has it done that’. Youngsters, on the other hand, simply submit to the way the application works, happily adopting all the tricks and techniques that the adults find so difficult.

Fortunately, us adults have YouTube to help us learn, which is exactly what I did with Fusion360 – laptop in front of me, iPad on the left, watching Lars Christiansen and copying the moves. My previous knowledge of draughting was really not much help, other than being familiar with the concept of X Y and Z planes. After maybe 18 months I’m no expert, but I am able to draw what I need to for the work I do – mostly working in wood, like this jewellery box:

28 December 2021 at 09:51 #577073

28 December 2021 at 09:51 #577073David Jupp

Participant@davidjupp51506Nigel,

Working in 3D CAD has much more in common with making and handling the real parts, than it does with 2D drafting.

Whatever 2D representations (drawings) you want will be semi-automatically generated from the 3D models.

Try not to think of 3D CAD as 'drawing' at all.

I'll go back to what I said earlier – I believe that you need to choose a system that somebody can show you at least the basics of, and answer your questions as you go along – then build on that with tutorials or a manual. Unless you pick up the basics, I don't think you'll ever find any 3D CAD system will make any sense to you.

Alibre, Fusion, SolidWorks, SolidEdge and many others work in a similar way (though lots of detail differences between them). My very limited exposure to TurboCAD suggests to me it works rather differently.

For low cost software, it is very difficult to offer one-on-one or small group training at a cost that anyone is prepared to pay. The less that people pay for the software, the less they are prepared to pay to learn how to use it.

3D CAD is not horribly difficult, BUT is does require a very different mindset from 2D CAD / manual drafting. You need to get some help to make that leap, or you'll struggle forever (regardless of which software you choose).

My comments are based upon experience live and remote training both novices and those with prior 2D CAD experience, in the basic use of Alibre Design. I've seen and heard that 'lightbulb moment' when trainees suddenly 'get it'.

Find somebody to help you, either in person or by live screen share. A few hours spent with a reasonably knowledgeable (patient) user will make a huge difference. The 2 day course that I used to teach was based on a few simple but structured exercises to cover all the main topics, and left enough time to look at specific items the trainees brought up.

Good luck in your quest.

Edited By David Jupp on 28/12/2021 10:18:49

28 December 2021 at 11:12 #577089SillyOldDuffer

Moderator@sillyolddufferPosted by Peter Greene on 28/12/2021 01:52:04:Posted by Nigel Graham 2 on 28/12/2021 00:28:21:I cannot see how drawing a piston in a cylinder is any easier in 3D than 2D projection, in CAD. Orthograpically they are circles and rectangles; isometrically, elliptical cylinders. Although the software plots them, you still need "tell" it where to plot them respectively to each other; and I find 3D the much harder mode.

Exactly what I meant when I said earlier:

"Prior exposure to 2D CAD is probably more of a liability than a help. "

Agreed. And David Jupp is correct when he says "Try not to think of 3D CAD as 'drawing' at all."

Thinking in 2D technical drawing mode is at the root of Nigel's CAD problems. I suspect TurboCAD was an unlucky choice because it supports 2D-CAD, and seems to fit in with Nigel's expectations. Unfortunately, 2D-CAD is stuffed full of features like Layers that are liable to confuse or invalidate 3D objects : the user has to understand when not to use them.

Nigel says: 'Orthograpically they are circles and rectangles; isometrically, elliptical cylinders. ' This is correct in 2D, but 3D CAD absolutely doesn't represent a piston as an isometric elliptical cylinder! Rather it's defined as a centre point with an X,Y,Z coordinate and a diameter, plus a dimensional property that extends the circle into a cylinder. (And many other properties such as 'made of Brass'.) The 3D CAD package can view objects from any angle, in perspective or isometric, make them transparent, render them realistically, or generate First or Third Angle Projections. CAD does most of the drawing, the operator defines shapes, usually by extruding 2D perimeters.

In 3D-CAD you don't normally 'draw' a piston in a cylinder. Rather, the piston and cylinder are defined as separate objects and fitted together. Although 3D-CAD starts by drawing simple shapes like circles, later stages are nothing like 2D. When creating 3D objects, it's vital they make sense internally: looking OK on paper might be 'good enough' in 2D, but 3D objects are highly particular. Separating 2D and 3D methods is vital because mixing them up causes chaos.

Nigel's strong desire to stick with outdated hardware and software is a complication. It makes life extra complicated, because there's no guarantee modern software will run on what he has. Not only necessary to understand a different CAD paradigm, and learn how a particular CAD package is organised, but it's likely a bunch of nasty incompatibility problems will have to be sorted too. The desire to 'keep it simple' by staying with a familiar operating system on older hardware becomes a viper.

I'm certain no 3D-CAD package meets Nigel's combination of requirements. None of them work as he expects, which is a show-stopper.

In an earlier post I suggested Nigel should build on his strengths by sticking with 2D-CAD. Perfectly respectable and LBSC managed with paper and pencil!

Dave

28 December 2021 at 11:13 #577091Nick Wheeler

Participant@nickwheelerPosted by Nigel Graham 2 on 28/12/2021 00:28:21:I cannot see how drawing a piston in a cylinder is any easier in 3D than 2D projection, in CAD. Orthograpically they are circles and rectangles; isometrically, elliptical cylinders. Although the software plots them, you still need "tell" it where to plot them respectively to each other; and I find 3D the much harder mode.

By assessing range of motion, do you mean by animating a 3D drawing? I could not reach those heights.

I would leave weights, c.g. and the like to industry. Though I have 'Excel' for parts-lists if necessary, if I could not count a dozen components, I could not make them in the first place.

I still have to design the thing, however I draw it.

If the method of drawing it helps me design it so much the better, but I still need learn to draw it; and I know that CAD represents a massive skills overhead on knowing how to design and make the thing itself.

Drawing a part in place isn't any easier than doing it separately. But having the relevant dimensions, axes, geometry and dimensions visible sure makes the design easier. That's what using a computer is supposed to do: take care of the time consuming maths, keeping track of parts, what goes where, what it's called, how it fits to other parts, turning the thing through 107.5°, reusing important dimensions like a bore size so that the piston changes as well as the bore if you decide to add a couple of mm, updating the workshop drawing and so on, freeing you to do the creative part. And that's just for a relatively simple round part that can be produced with just a couple of profiles.

Animating an assembly is inherent to attaching one part to another; it's not like cutting one flat part out of the sheet you drew it on and pasting to another. Instead you allow a crankshaft to rotate in its bearing caps, the conrod to rotate about the big end, piston around the gudgeon pin, and piston to slide on the bore axis. They're all separate and adjustable. Turn the crank, and the whole assembly moves and clears other areas as intended. Or it doesn't, which means you get to fix it before wasting expensive time and material making parts that won't work.

Fixing it could be as simple as rotating the crank to where the conrod touches the base of the cylinder liner and using a boolean operation to make the part cut its own clearance. You know what you want but not the details – how deep, what angle, how does this curve change along that angle – all of which the computer does with a couple of mouse clicks. I know there's a load of technical stuff going on to do that, but I don't want to spend months working out how to do it; A-level maths was almost 34 years ago!

2D CAD reduces the technical skills you need to able to design something. 3D CAD takes on even more of them. But they are complicated programs, so some thinking and practice is needed. That thinking might be contrary to what you already know, which is what is happening here. What helped me was a lecture at an ME exhibition at Stoneleigh, where these concepts were explained by demonstrating the basic design work on a single cylinder crank, case, barrel, piston and rod. I still think that having someone do the same for you with a simple assembly you already understand, perhaps a QCTP/lock/throttle body/spindle/whatever, would turn on the cartoon light bulb in your head.

As for which program to use, that depends on too many things for us to decide for you. Fusion's UI actively removes options that can't be applied: click on a straight line and it greys out the concentric constraints, you can't extrude an open profile etc. I tried Solidedge and it was like stepping back twenty years – lots of tiny impenetrable icons constantly on display, different terms for the same concepts that were coined by people trying to show off how clever they are and the rotate and zoom controls reversed which

wasis incredibly frustrating. I could retrain my brain to use it, but currently have no reason to do so.28 December 2021 at 13:11 #577131Nigel Graham 2

Participant@nigelgraham2Peter –

Sorry, but while others may, I don't make that link about "prior exposure to 2D" draughting.

My point is that with any CAD package, you need learn how to to fit drawing's objects together properly, whether in 2D or 3D. Nothing to do with the projection, but as with any other complicated software, you need know how to "ask" it to perform the task.

===

Despite been taught manual Technical Drawing at school (my only A-Level from there!), using loose T-square and set-squares, and using conventional engineering-drawings at various times at work and home since; I do not see CAD as a direct digital version of those skills, in both orthographic and isometric projection.

Instead I see CAD as its own way to perform a given task. Its parallel with manual draughting is the result (the drawing) not the way to it. So I knew from the start to see CAD in its own right; as a digital plotting system, not electronic species of ebony and ebonite.

Similarly, my mainly-orthographic background does not colour my view of isometric CAD "models", though orthographic projections are more useful to me. Isometric projection has always been important in technical drawing – but is slow and difficult manually, needing considerable geometrical constructions. 3D CAD does all that constructing, but its use replaces one lot of difficulties with another.

Nothing to do with familiarity with orthographic drawings.

'

I reject the assumption that the only way to make any workshop drawing is via a 3D CAD model. I found it a very difficult long way round from envisaging an item to the drawing that guides making it. The 3D model did not help me even just draw the part; certainly not to design it. For a 3D drawing to help me design it, a rough sketch on paper is far easier and quicker.

Some 3D-first advocates argue it by our living in a 3D world, designing 3D objects. Fair enough, but often we can, and may need, see only one elevation at a time; and usually need full orthographic views to be able to make the item.

So how might 3D CAD drawings be useful to me? Errr… I am not sure, but I may as well have the opportunity. Yet the drawing is only a means to an end; and " because we can " or de rigeur, are no reasons at all. So I thought of when I first considered using CAD.

At work I frequently saw orthographic drawings with small, explanatory pictorial renderings helping the machinist visualise the part; and sometimes, 3D assembly-drawings. Hemingway uses the same approach on their kit drawings. I could see the advantages CAD offers over manual draughting, and decided to look further; encouraged by two other contemporary matters.

1) Serious problems with my steam-lorry project, by having to design and draw it from only a few old photographs, so at times I nearly abandoned it. If CAD could help me make decent drawings more readily, it might help me design the vehicle – I had no idea of CAD's difficulty, only its purposes.

2) CAD was appearing in model-engineering. Paul Tracy started advertising TurboCAD in our magazines: the only industrial-quality CAD package available, and at sensible prices, to we amateurs.

So I went for it!

'

TurboCAD allows both immediate orthographic elevations and 3D modelling, fortunately because I have learnt the former, with a struggle, to an adequate level; but the latter is far harder. I feared the later Fusion and Alibre rivals' 3D-first approach as a huge, additional IT barrier between rough pencil sketch and functional workshop drawing.

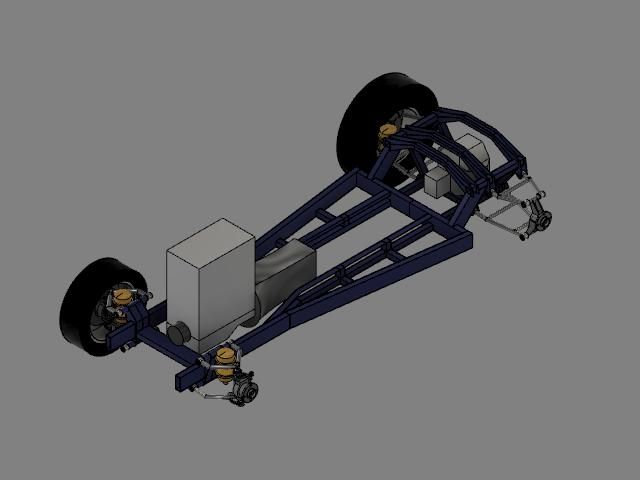

Yet 3D is potentially useful to me, for certain, limited purposes; e.g. preliminary sketches and layout drawings. I cannot expect reaching the level Nicholas shows with his car engine.

So I would like to be able to make three-dimensional, low-detail sketches of single parts or simple assemblies like that hand-pump; and even to represent an entire machine by sub-assembly outlines – e.g. my steam-wagon but to better than I showed.

If Solid Edge (C) is easier to learn than TC it may advance my CAD skill enough for me to do those, to a useful level.

It all has nothing to do with my orthographic background, but very much with how easily I can learn the sotfware!

28 December 2021 at 13:48 #577143David Jupp

Participant@davidjupp51506Posted by Nigel Graham 2 on 28/12/2021 13:11:25:So I would like to be able to make three-dimensional, low-detail sketches of single parts or simple assemblies like that hand-pump;

3D sketches are only used for very specific things in 3D CAD (and are not even available in all products). For now don't even think about 3D sketches.

2D sketches are the basis of all 3D parts.

28 December 2021 at 15:37 #577159SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 28/12/2021 13:11:25:

…

It all has nothing to do with my orthographic background, but very much with how easily I can learn the sotfware!

Nigel, many of us have noticed you seem to have a strong 2D mindset. It flashes like a beacon throughout your posts. If it looks like a duck and walks like a duck, perhaps it is a duck?

If we're correct, it's the reason you can't easily learn the software. A 2D mindset is a fundamental road block to taking 3D-CAD on board. Nothing to do with intelligence – it's roughly equivalent to a classics scholar trying to learn an oriental language from his trusty Latin Grammar.

I think you'd get on much better with a basic 2D CAD package – not TurboCAD, AutoCAD, or any of the other big boys because they're packed full of confusing advanced features. QCAD / LibreCAD does more than I need, others available!

Dave

28 December 2021 at 16:08 #577164Nigel Graham 2

Participant@nigelgraham2Dave (S.O.D.) –

I appreciate that assembling a 3D drawing needs to be very accurate, but I know the programme does that provide you can use it correctly. My sticking-point is knowing how to ask it do that, in any CAD package.

I have no "strong desire" to use "outdated" software. Only to use appropriate software; though I don't approve of the IT industry's commercial obsolescence methods. After all, we don't buy a new lathe every couple of years, but only to replace an old one worn beyond economical repair, or with one that genuinely will better suit our needs.

SO…..

I am preparing to up-date my PC from WIN-7 to WIN-10, and for safety have aready copied everything to two independant solid-state drives.

PC security apart, this will give me three CAD options: continuing with TurboCAD 19 Pro, buying its new version, or at least trying SolidEdge Community. The latter TC almost certainly and SEC definitely, are written for WIN-10 anyway.

My reason for using CAD has not changed, what I want from it has not changed; my design and building abilities have not changed. I woul dthough my CAD abilities to improve, and that includes trying to learn 3D CAD enough to be fairly useful. I know I could not reach its advanced levels and I doubt I need its more rarified aspects anyway.

'

I am afraid that though I appreciate CAD helps you to design machinery, I cannot see how it reduces your skills as a designer. It does the formidable plotting maths and geometry for you, yes; but you still need understand what you are designing, its materials and how to make it. Also to avoid the CAD trap I have seen in professional drawings, of mathematically correct details very difficult and inefficient, even impossible, to make.

Rather, I think the skill level about equal. CAD has exchanged your geometrician's skills with your IT skills.

'''

David –

By "sketch" I meant simply any rough preliminary drawing or layout, lacking fine details, line formats, etc.; as a basis for the proper workshop drawings.

Not as the generating-lines for 3D extrusions. I forgot Fusion's terminology!

The "sketch" of my part-built steam-wagon is just that – a "sketch", despite a 3D image to the real dimensions, comprising many extrusions and primitives.

E.g. I Assembled one channel-section chassis rail from three Extrusions of a figure made by Adding three "box" (cuboid) primitives. The other is its Mirror-copy about the chassis centre-line.

It shows the vehicle's layout, and if I knew how to take off and dimension its elevations, it would help further work; but is still only a sketch, and a very crude one at that.

28 December 2021 at 16:37 #577170Nick Wheeler

Participant@nickwheelerYour steam-wagon is the 3D CAD model of a 'back of the envelope' sketch.

That isn't an insult, as they are are just as useful as ones done in pencil on an actual envelope. It allows you to develop what are important features, where the datums are, not to use the primitive solids(seriously, don't use them) and dimensions that you can establish as parameters before you start on a more sophisticated model. One like this, which might look finished but only a few of the measurements are final, the rest are based on incomplete tape measure work or educated guesses:

Your work shows that you are on the right track, but just need some encouragement from a more experienced person. The pump would be a good place to start.

28 December 2021 at 16:41 #577172David Jupp

Participant@davidjupp51506Nigel,

In most 3D CAD the terminology has very specific meanings.

2D sketch – a simple profile that is used to define the outline (shape/size) of a 3D Feature. The Feature when combined with other Features will produce a Part. A sketch is not unlike a traditional 2D drawing but contains much less information – it needs just enough to define a part outline, or perhaps a hole. It definitely doesn't define the entire part. Keeping sketches simple makes later editing much easier.

3D sketch – typically a path in 3D space, might be used for example to Sweep a 2D Sketch along to produce (for example) a piece of formed pipe. 3D sketches are not used very often – they tend to be tricky to produce. The same result can often be achieved with 2D sketches (perhaps on newly added reference planes). I would suggest avoiding them in the early days.

Your use of terminology contrary to how it is usually used in 3D CAD is probably not helping you to follow what other are saying, and vice versa.

I don't know enough about TurboCAD to make any fair comment about it, so I won't criticise it.

In most 3D CAD systems you can very easily both set and change the sizes of features after doing the initial sketches. Ease of making changes as a design evolves is a major strength of 3D CAD.

Measurement tools are provided in the 3D workspace.

Workshop drawings can be prepared from any part or assembly, by switching to the 2D drawing module – choose paper size, scale, required views, place dimensions (which are automatically populated). Better still, if you edit the part/assembly (change size, or add a hole) the workshop drawing updates to reflect the changes – no need to re-draw anything. If you later want to change the sheet size or re-scale a view, it takes a few seconds.

I would do a screen share session for you to run through this – but it would be Alibre based, which you've already decided against. It would be best not to confuse you further even if the basics are similar to most 3D CAD systems.

28 December 2021 at 18:50 #577195Nigel Graham 2

Participant@nigelgraham2Thank you for the encouragement and tips.

Nicholas –

The terms I use are as both conventional draughting in any medium, and in IMSI's TurboCAD.

What is the problem with the Primitives?

The pump drawing is mainly of extrusions, but their generating forms (the "sketches" then, in other CAD versions) were from the tool-bar library of plane figures including the hexagons for the nuts. I think I made the cut-away portion by extruding a 'C' by circles and lines, but might equally have used 3 primitives by 'Subtracting' a cylinder and a cuboid from a larger cylinder. The foot is certainly an extrusion. The ram, pins and links were probably a mixture of library 2D and 3D figures. I would have inserted the ram by making its and the cylinder's axes equal by co-ordinates, then applying the appropriate single-axis move.

'

David –

I have not seen the word Sketch used in TurboCAD, so opened TC then its "Help" site to find out. Sadly though, IMSI's pdf document opens at Page 1, but no longer works. It froze and I had to use Task Manager to close it – a WIN-7 / Firefox/ Adobe conflict? Eventually, I found Sketch among the tool-bar commands, and added it to the appropriate tool-bar to experiment…

…. In IMSIan, "Sketch" is literal. It allows you to scribble free-hand with the mouse!

'

Using TurboCAD's 2D/3D switch wrongly can cause very baffling havoc with the workplane; apparently one of the most common TC beginner's mistakes. I think to take off an elevation from a model you set the workplane temporarily on the view's "nearest" facet.

'

That cross-linking of dimensions does not seem to happen in TC, at least not in the 19 Pro edition. Nor can you dimension a 3D view, only an elevation or plane figure. I don't know if changing a dimension is automatically reflected in its copy elsewhere. It might if an "associative" dimension, whose value tracks altering the entity.

'

I have just tried another, existing 3D drawing – two cross-heads, one sectioned lengthways with its cut-off part slid backwards to show the cavity and pin, plus the piston-rods and pistons – to see if I can make sense of the above.

Instead I selected by a simple slip, "Edit Mode": a peculiarity of unknown purpose, irreversible without closing and re-opening the whole programme! The Sketch tool would not go to sleep either. These stopped me doing what I was attempting. I tried to copy the simply-rendered image to Paper Space, and yes, that too reverted to wire-frame form.

Among other things, I found I was incorrect previously: IMSI calls its projections, Isometric and not orthographic but Dimetric! Where the heck did they find that word? Shorter caption, I suppose. I've managed to delete Sketch from the tool-bar though.

Maybe it's time I did move to a less frustrating CAD programme!

'

Alibre – I decided against it when MEW was promoting it. I tried Part 1, maybe Part 2, happily enough, in copies bought in the shop. I started a subscription but it somehow skipped 1 or 2 issues. The unexpected break made me realise I was trying to learn – and would eventually need apparently subscribe too – a totally different replacement for a fully paid-for system in which I was beginning to make some headway.

29 December 2021 at 13:02 #577289 Gary WoodingParticipant@garywooding25363

Gary WoodingParticipant@garywooding25363Nigel: Just to whet your appetite, try creating a line drawing in TCAD containing…

Two lines from a point – 1 vertical and the other horizontal – like the +X and +Y axes of a graph.

At the point of intersection, ie locn 0,0, draw a square of side 12 units.

Now draw a line, 35 units long, that just touches the two lines and just touches the corner of the square.

And yes, I know it's a very old puzzle that's a pig to calculate, hard to draw in TCAD, but trivial in Fusion or any other modern 3D cad system.

29 December 2021 at 17:16 #577333Nigel Graham 2

Participant@nigelgraham2Gary –

Ah, the old ladder puzzle: the ladder has to reach as high up the wall as possible despite the obstacle – never mind the 1-in-4 safety rule!

That is how I have seen it in a maths text-book. I soon realised calculating it would be impossible for me, with having to derive either extremely advanced trigonometry, simultaneous equations in x and y with both values squared and possibly calculus. Or all three. It roused a vague memory of a slightly similar locus problem in A-Level Technical Drawing; and whose principle was used in a shaping-machine attachment for generating large concave curves by raising the work end as the table is traversed past the ram.

It proved easy to solve to 4 places of decimals in TC – a very simple drawing but a rather tedious set of iterations. It certainly shows the fractional definition that CAD gives!

Appropriate Snaps set, some preliminary experiments with a 35mm dia circle at (6, 6) and two extended diagonals narrowed the search area to a provisional foot at about (8, 0).

A cross-hair at that point, join its intercept to the (6, 6) vertex, produce that line to cut the y-axis then measure its length (diagonal dimension.)

Delete the line, nudge the cross-hair a bit, repeat the slope and measurement…

Delete…..

Eventually down to 0.002mm cross-hair steps.

I stopped at slope length 34.9997 units (actually mm).

This gives intercepts at (7.2750, 0) and (0, 34.2353)

….. Close enough?

(I suppose you'll now you go and tell me there is a construction that solves it in one go!)

+++++

I have decided as far as IT goes I may be best buying a new system, lower-range as I don't use my PC for games/entertainments, but still WIN-11 straight off or WIN-10 with up-rate capability. The retailers are still selling both. Really I need find an independent dealer – they and I are more likely to understand each other than some bright young thing in the anything-leccy emporium under the sign of highly-spiced foods or horse-rakes.

That can run accept and run whatever CAD system I then choose: the new TC or SolidEdge Community; but I will keeping the one I'm using now (WIN 7) and all its programmes and files for off-line use and back-up. (I still have my old, ex-works, WIN XP computer all set with monitor, kbd, mouse.)

I found yesterday that TC's on-line Help won't appear. Perhaps IMSI has made it W10-only. I tried to find out via its Forum but my password won't pass either, and my attempt to obtain a new one failed.

TurboCAD allows saving drawings in a wide variety of file-types. These include DWF, DWG, DXF. Am I right thinking those are more or less industry-standards so SolidEdge (or Alibre or…) should read them?

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Problem getting the right parameters on a VFD

Started by:

Robert Graham in: Electronics in the Workshop

- 4

- 5

-

5 April 2025 at 13:38

Craig Brown

-

How to wire up 3 phase motor and 3 phase converter?

Started by:

ell81 in: Beginners questions

- 7

- 13

-

5 April 2025 at 12:35

Robert Atkinson 2

Robert Atkinson 2

-

Flattening brass plates

Started by:

t1krt in: Workshop Techniques

- 1

- 1

-

5 April 2025 at 12:21

t1krt

-

Morse Key

Started by:

Steve Withnell in: Work In Progress and completed items

- 2

- 2

-

5 April 2025 at 11:43

SillyOldDuffer

-

James Coombes Drawing Error (or mine?)

Started by:

Steve Withnell in: Drawing Errors and Corrections

- 4

- 5

-

5 April 2025 at 10:51

Steve Withnell

-

Myford S7 Taistock Adjustment

Started by:

Harry Wilkes

in: General Questions

Harry Wilkes

in: General Questions

- 9

- 11

-

5 April 2025 at 08:53

Martin Kyte

-

Measuring increments on boring head

Started by:

Bill Phinn in: Workshop Techniques

- 15

- 18

-

5 April 2025 at 08:48

Bo’sun

-

Flexispeed Meteor 2

Started by:

ferroequinologist in: Manual machine tools

- 11

- 19

-

5 April 2025 at 07:01

ferroequinologist

-

What Did You Do Today 2025

1

2

3

4

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 23

- 78

-

4 April 2025 at 20:57

Nigel Graham 2

-

Powered hacksaw – blade lift for the return stroke

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 17

-

4 April 2025 at 20:00

Nicholas Farr

Nicholas Farr

-

Damp proofing concrete floors

Started by:

Duff Machinist in: General Questions

- 13

- 13

-

4 April 2025 at 19:57

Bazyle

Bazyle

-

New member old lathe

Started by:

t1krt in: Introduce Yourself – New members start here!

- 8

- 16

-

4 April 2025 at 19:52

t1krt

-

Elliott Omnimill Quill Clamp

Started by:

dangermouse in: Manual machine tools

- 3

- 3

-

4 April 2025 at 19:23

Bazyle

Bazyle

-

Tangential tooling

1

2

Started by:

Keith Matheson in: Workshop Tools and Tooling

- 13

- 29

-

4 April 2025 at 18:14

Howard Lewis

-

Which lathes have drawbars in the headstock?

1

2

Started by:

ell81 in: Beginners questions

- 17

- 26

-

4 April 2025 at 18:04

Howard Lewis

-

Stripped aluminum threads. Now what?

1

2

Started by:

brucemc777 in: Beginners questions

- 19

- 33

-

4 April 2025 at 16:34

old mart

-

gear cutting with the shaper

Started by:

jacques maurel in: Workshop Techniques

- 5

- 6

-

4 April 2025 at 15:15

Andrew Tinsley

-

Machinery Handbook

1

2

Started by:

Dalboy in: Books

- 30

- 37

-

4 April 2025 at 12:27

SillyOldDuffer

-

Electric motor vibrations

Started by:

Sonic Escape

in: General Questions

Sonic Escape

in: General Questions

- 8

- 12

-

4 April 2025 at 07:38

JasonB

JasonB

-

Build Your Own Metal Working Shop From Scrap (7 book series)

Started by:

Dr_GMJN in: Books

- 6

- 7

-

4 April 2025 at 06:39

Pete

-

Scraping

Started by:

ryan.carter848 in: Books

- 7

- 10

-

4 April 2025 at 05:11

Pete

-

Ml10

Started by:

keel in: Beginners questions

- 5

- 7

-

3 April 2025 at 23:06

duncan webster 1

-

Warrington Model Engineering Developments

1

2

Started by:

colin wilkinson in: General Questions

- 14

- 41

-

3 April 2025 at 20:26

keel

-

Vice as Broaching Press

1

2

Started by:

James Hall 3 in: Beginners questions

- 16

- 37

-

3 April 2025 at 20:00

JasonB

JasonB

-

UK consumer protection laws?

Started by:

Fulmen

in: General Questions

Fulmen

in: General Questions

- 8

- 10

-

3 April 2025 at 19:07

Fulmen

Fulmen

-

Problem getting the right parameters on a VFD

-

Latest Issue

Newsletter Sign-up

Latest Replies

- Problem getting the right parameters on a VFD

- How to wire up 3 phase motor and 3 phase converter?

- Flattening brass plates

- Morse Key

- James Coombes Drawing Error (or mine?)

- Myford S7 Taistock Adjustment

- Measuring increments on boring head

- Flexispeed Meteor 2

- What Did You Do Today 2025

- Powered hacksaw – blade lift for the return stroke