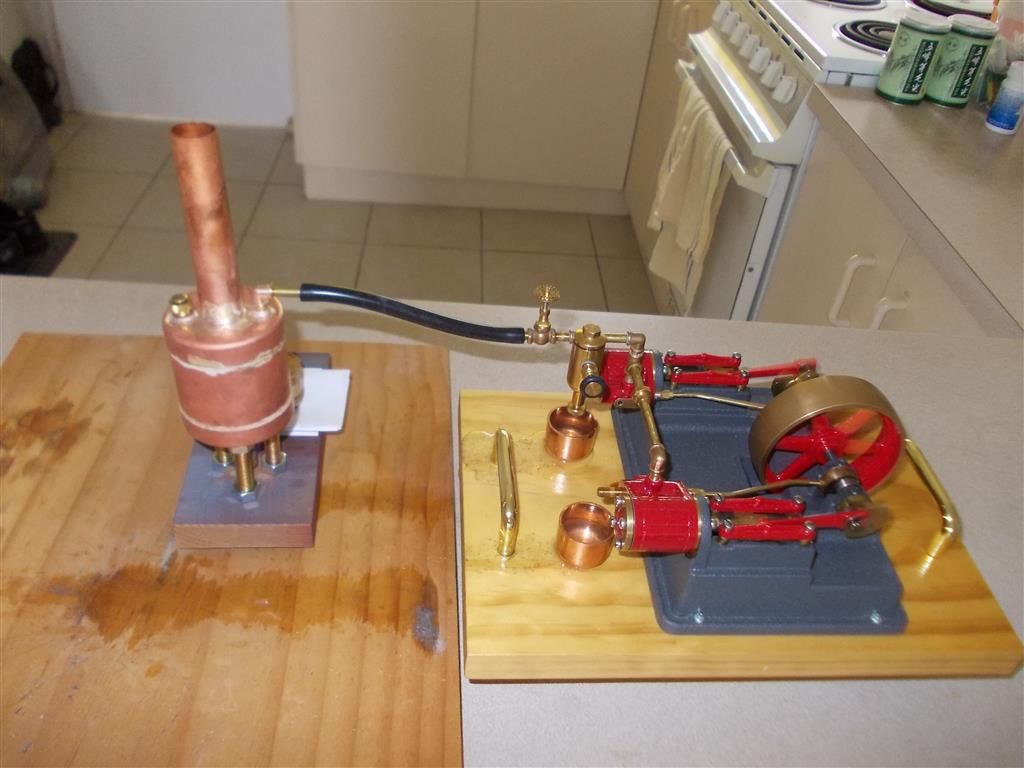

I went to the scrap yard this morning and a found piece of copper tube which fitted nicely over the brass tube. I also found some copper tube the exact same size as the brass chimney so next time I build one of these I will use a full copper chimney right through which is what Midwest should have done in the first place. I decided to remove the damaged part of the brass chimney ; I think this was a mistake as it would have helped keep everything upright by leaving the full chimney intact.

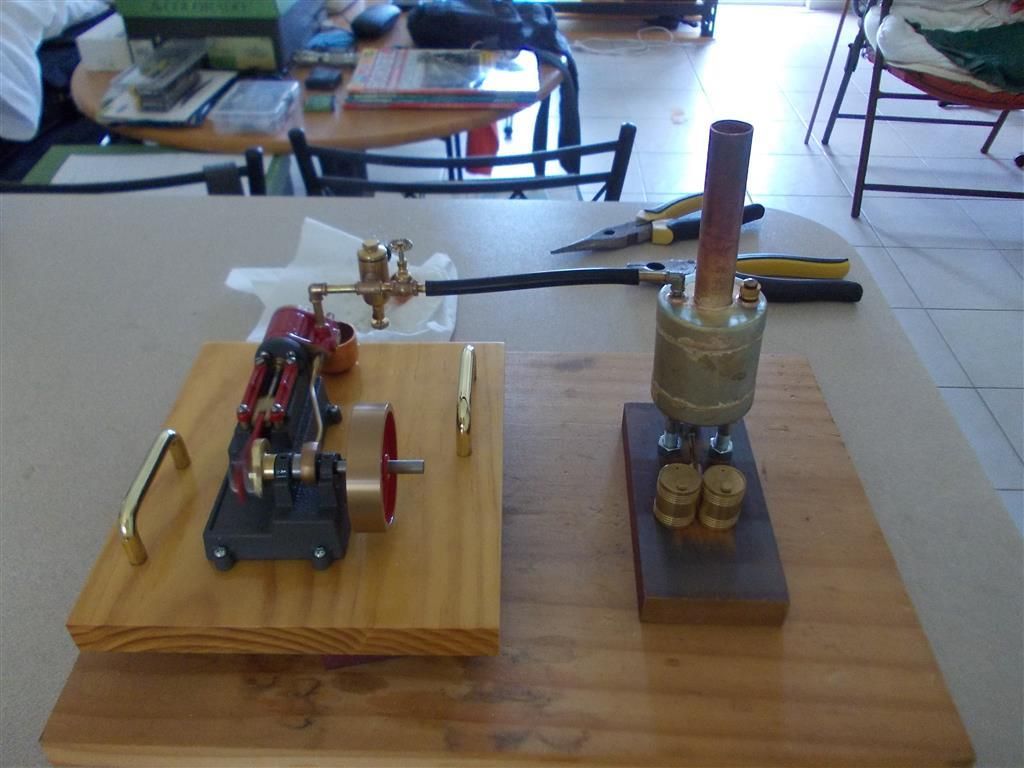

As you can see from the photos below, after the solder had hardened the chimney is not perpendicular…very frustrating as it was perfectly straight when I started soldering. I suspect that the top of the boiler may have changed shape and buckled a bit or the copper sleeve was not as good a fit as it could have been.

After putting it in the pickle for one hour a decided to give it a quick test to see if it actually produces steam as there would be no point putting the insulation and wooden lagging on if there was a leak somewhere. In the photos below it is not actually under pressure as I left the fitting out for the steam outlet but the water does boil and steam comes out of the hole so something should happen when I connect it up.

I really must buy another one of these and do it properly next time ; both the boiler and the engine could have been much better. I am not sure if it worth trying to remove the copper sleeve as that would require a lot of heat and it may ruin all the other solder joints.

NOTE : It does not look too bad in the photos but it is actually quite bad……seriously thinking of grabbing the blow torch and trying to remove it !

Edited By Brian John on 10/12/2014 03:10:04

Edited By Brian John on 10/12/2014 03:10:53

Edited By Brian John on 10/12/2014 03:34:07

Brian John.

.

.

.jpg)