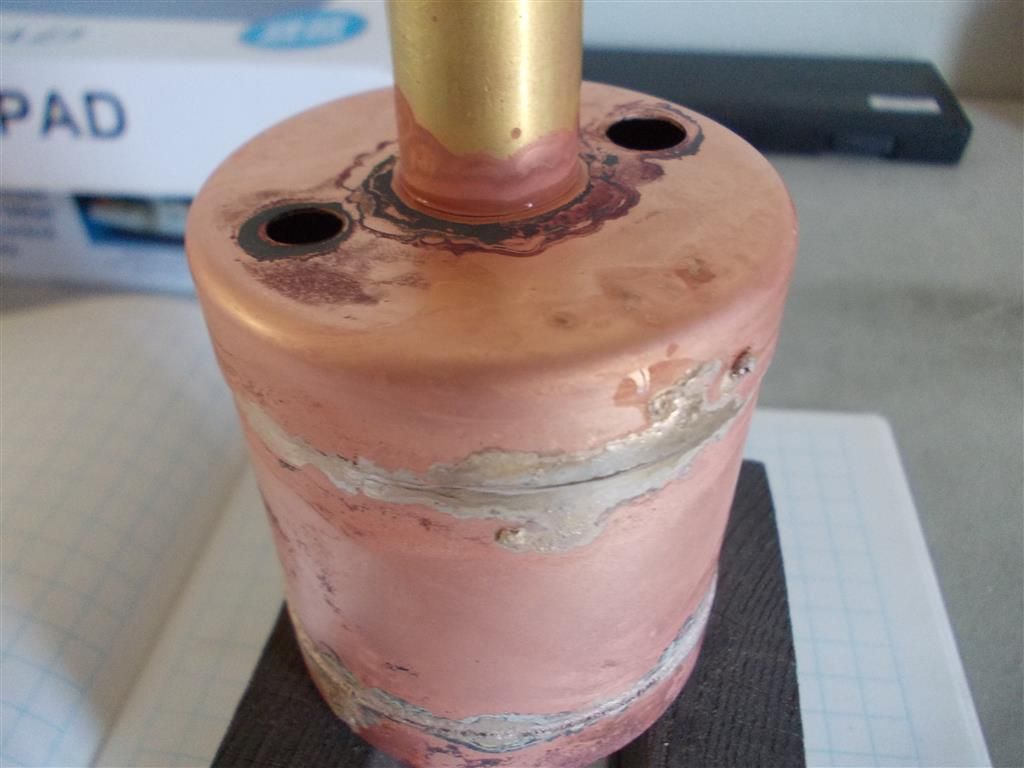

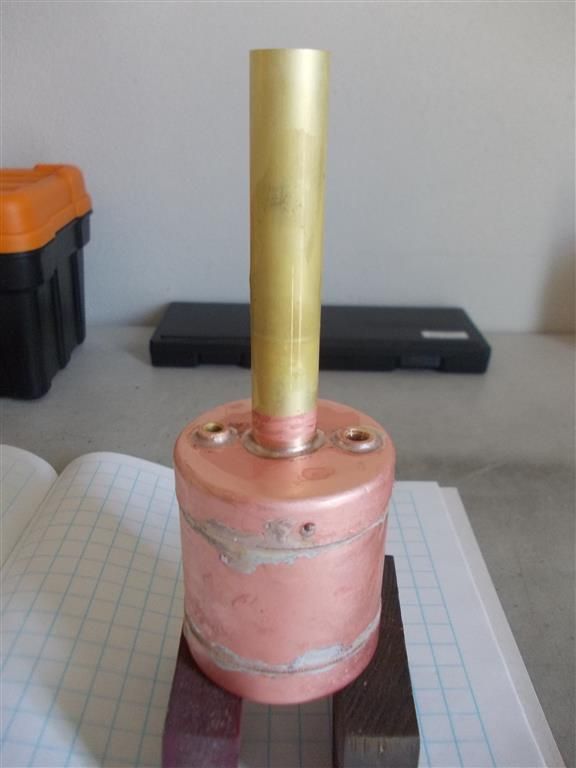

Placing solder around the joints : Yes, I did it this way when I was soldering the cylinder to the spacer. I did not have the full flame burner then and I could not get the metal hot enough to solder it properly. But by heating the metal parts as hot as I could then heating the solder which I had already placed in position I was able to achieve a good join.

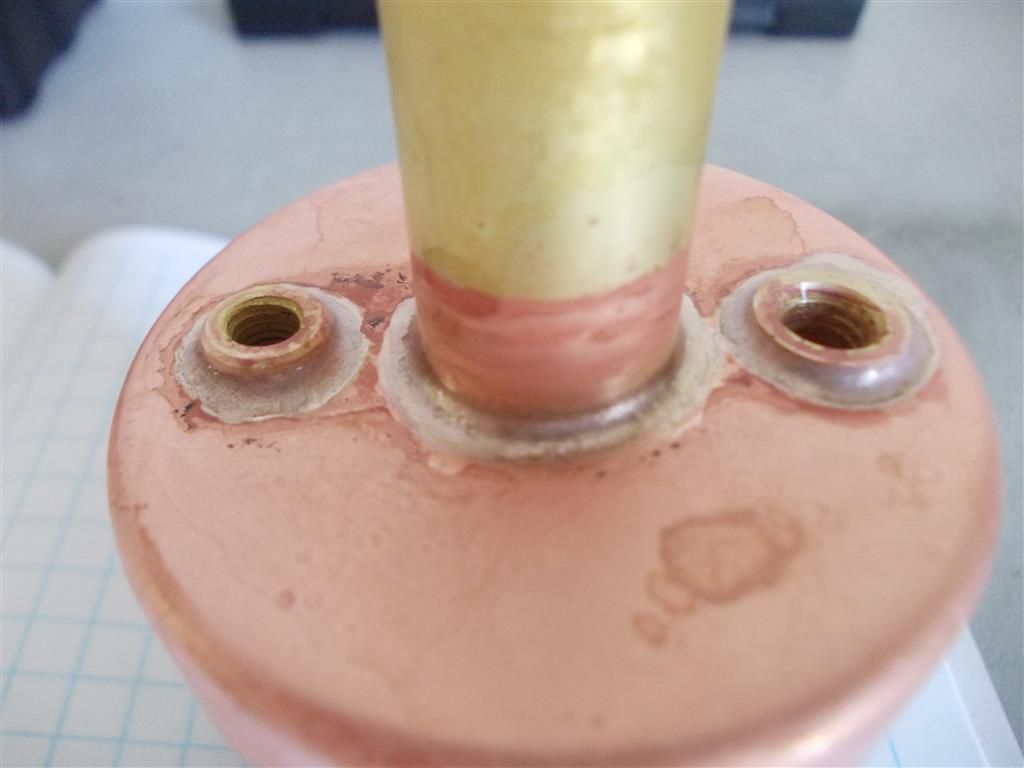

I think you can only do it this way when you have a ''horizontal ledge'' on which to place the solder pieces. This method would not work when soldering the top and bottom caps of the boiler but it I may use this method when soldering the chimney, steam outlet and safety valve.

1. It is good to know that the solder has a higher melting point when heating it a second time. That is very useful information. Why is it so ?

2. Placing the metal parts in citric acid for a few hours seems to get everything much cleaner then using sandpaper. Is this an acceptable method to clean the metal prior to soldering ?

Edited By Brian John on 06/12/2014 08:32:32

Edited By Brian John on 06/12/2014 08:32:52

Edited By Brian John on 06/12/2014 08:40:42

Brian John.

I have a small courtyard outside the apartment.

I have a small courtyard outside the apartment.