Posted by ega on 03/08/2022 09:45:31:

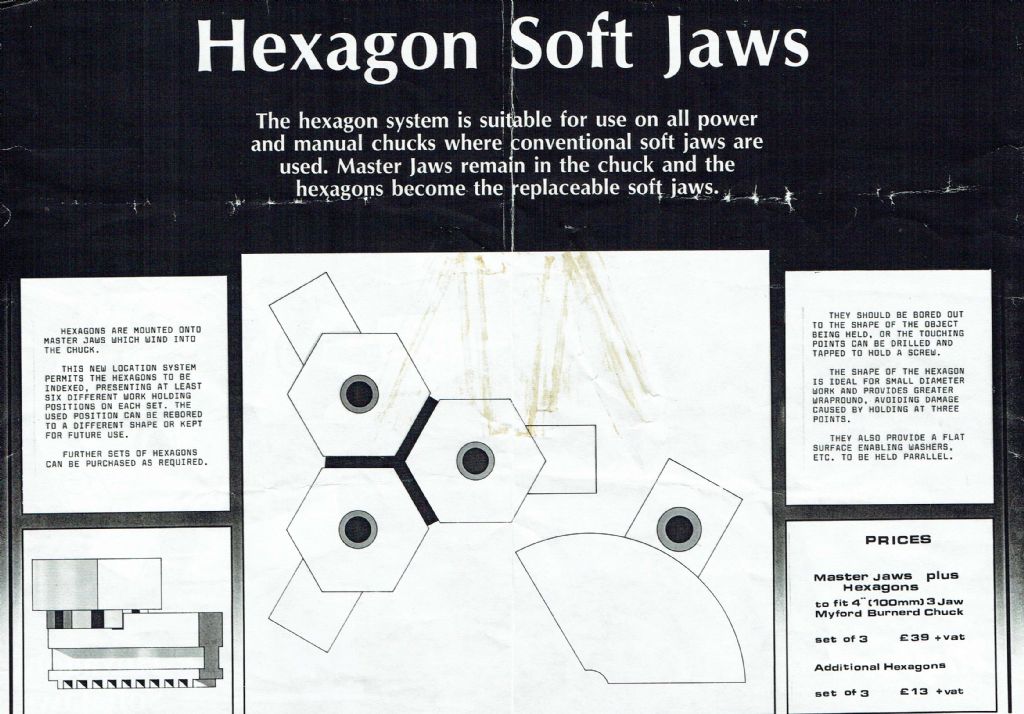

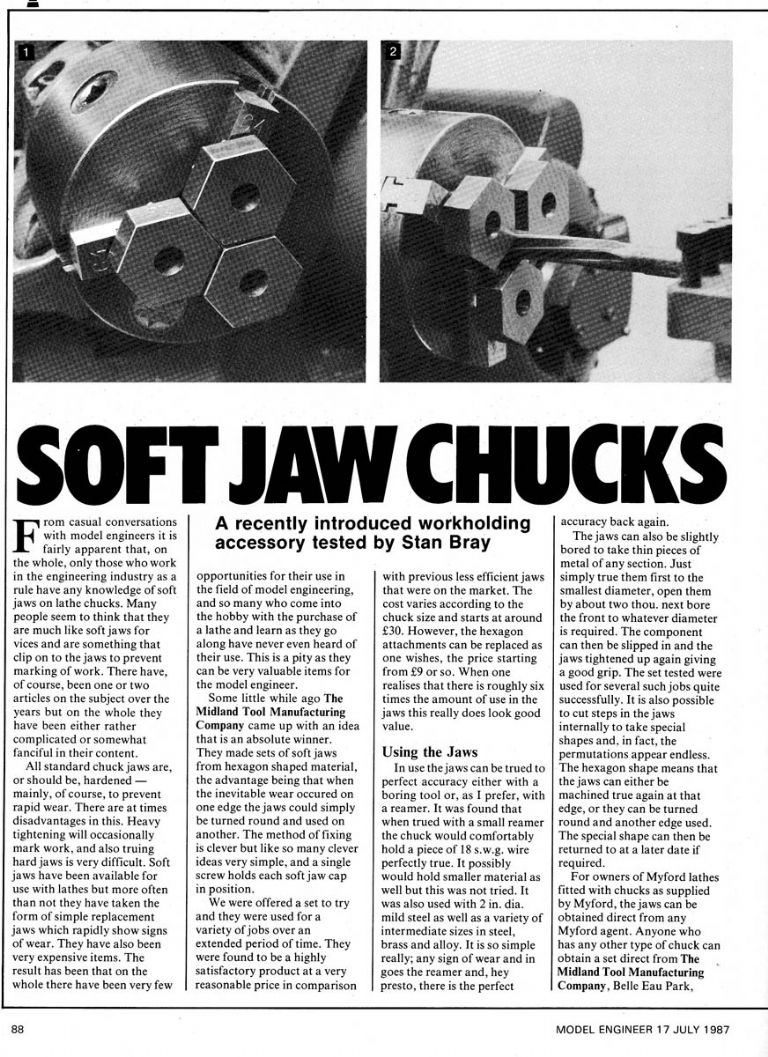

The precise construction is not clear, to me at least, from the Myford leaflet

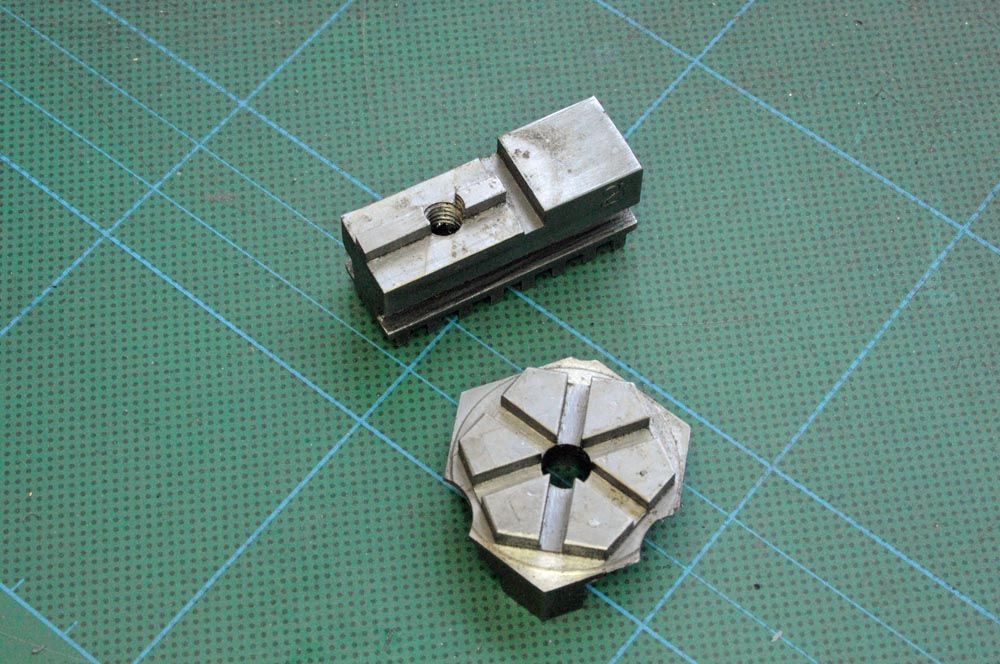

The photo below the Myford leaflet explains it very well. The groove in the hexagon locates in the tongue on the base jaw. The flat of the hexagon (which is perpendicular to the groove) locates on the step in the jaw, the back side of the cross-groove milled in the jaw.

It relies on the pressure from the work pushing the soft jaw against the step, so only five out of six degrees of restraint are provided, so you could not grip the inside of a tube with the jaws, but for normal, external gripping, it should be highly repeatable.

The concept is 50% of a traditonal tenon-and-groove two-piece jaw setup. See for example,

https://www.chestermachinetools.com/product/3-jaw-self-centering-2-piece-jaw-chucks-plainback/

Soft Top Jaws for Bison 2 Piece Jaw Chucks American Cross Tenant By Bison

For information, this type of jaw is made to ASA B5.8 or IS 15248 2002 or ISO 3442 (and the dimensions in the international versions are direct metric conversions of the original imperial units).

Have a look at 11:47 onwards here: https://www.youtube.com/watch?v=JplJAxX3buA

Harry Wilkes.

Harry Wilkes.