@Pete – I need the metal to stay absolutely flat after it has been cut.

In my experience sheers never seem to achieve this.

@David George 1 & John Haine

Yes from what I understand, small desktop circular saw-type machine can't properly 'cut' mild steel because they spin to fast. I am also slightly nervous about the rear (rising) edge of the thing, but at least they will cut in a straight line (unlike a manual hacksaw!)

So my instincts are to go for some kind of 'grinding' cut rather than a cutting blade.

I googled it but to be honest, I don't really know what a "surface grinder with a slitting blade" is!

I am assuming that that tile-cutter does its cutting with a grinding wheel – probably with diamonds in it. That's an interesting line of thinking! Even if the build quality looks v cheap & sure enough the reviews are terrrible.

Fwiw, here's another one:

==> "QEP Diamond Wheel Wet Tile Cutter 450W"

https://www.screwfix.com/p/performance-power-ptc450e-450w-electric-tile-cutter-230-240v/469gt

110mm "general purpose" diamond blade,

"For wet cutting only. General purpose will cut: ceramic, marble, granite, stone."

– 'suspiciously cheap' at £34. Build quality looks low for precision work, but at least it is well reviewed.

Designed to be cooled by water it seems.

450w, 8Kg, but rather slow – just 2950 rpm. My steel parts will just get hotter and hotter, me thinks without being removed fast enough.

Can anyone tell me how well a diamond-embedded blade cuts mild steel?

I was very struck but just how well aluminium oxide & Corundum cutting disks cut steel, using my hand held highspeed drill (20,000RPM) but only once you get them up to very high speeds.

Unfortunately mine is only 40watts (an old MICROMOT 50/EF) and torque suffers, but it does the job.

One option would be to uprade to a more powerful drill that has better control of torque

Precision drill/grinder FBS 240/E **LINK**

"For drilling, milling, grinding, polishing, cleaning, carving and engraving."

"The full wave electronic speed control results in virtually constant torque, even at lower speeds,"

5,000 – 22,000rpm. 100W. Weight 450g.

My main problem then becomes finding a circular table type housing to mount the thing on.

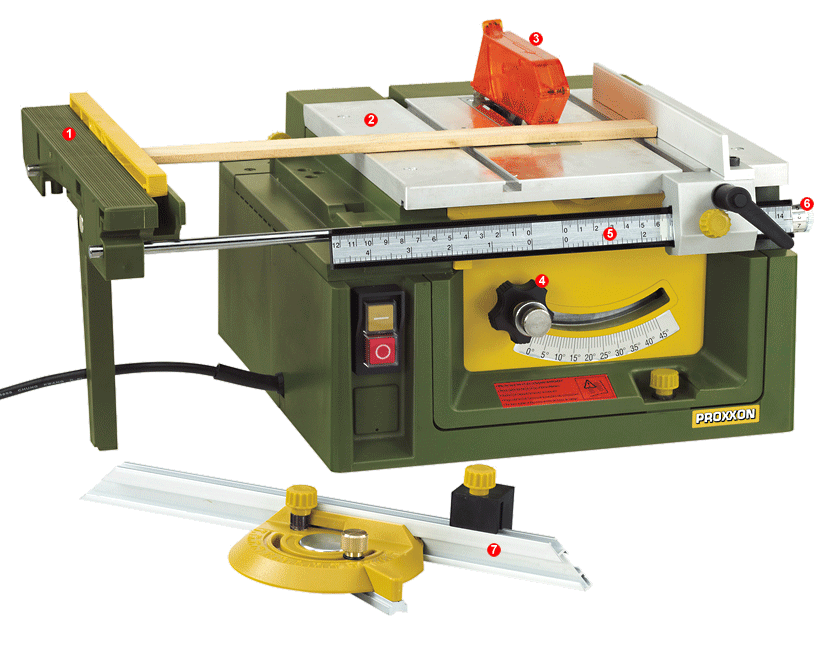

…Which takes me back to the Table saw FET (IF I stay with Proxxon – which in many ways I would prefer not to!)

HOWEVER the FET Table Saw is only 7000 RPM even though it is more powerful thant the hand tools (being 200watts), so I don't think it will cut very well using abrasion.

@JasonB

Re I'm still thinking about a milling machine. Buying a Sherline would be a huge investment for me.

PROXXON SOLID CARBIDE SAW BLADE

https://www.axminstertools.com/proxxon-solid-carbide-saw-blade-702072

@Roger B – that 50mm Proxxon solid carbide blade 28 011 may cut steel but it's certainly not designed to do so "non-ferrous" only.

@JasonB – Call me unusual, but my brain simply cannot function with flashing graphic like that. I have a zero tolerance of flashing adverts.

@Stuart Munro 1 – I thought those "Stanley 20-800 Adjustable Angle Clamping Mitre Box"

do look interesting. But can they cut steel? At a quick look, I thought that they were only for wood, no?

IF they can cut steel then they DO look useful but they won't allow me to cut sheets of material

(plust they are a fraction bulky… and won't be able to cut very thin stuff…)

MY THINKING THUS FAR

So far I am still leaning towards a small, high-speed, "circular saw type" design, but using a grinding process to do the cutting, and probably using a reinforced aluminium oxide or Corundum disk. I know it will wear but I don't think that will matter.

J

Edited By John Smith 47 on 21/04/2021 12:22:51

Edited By John Smith 47 on 21/04/2021 12:27:13

Michael Gilligan.

Michael Gilligan.