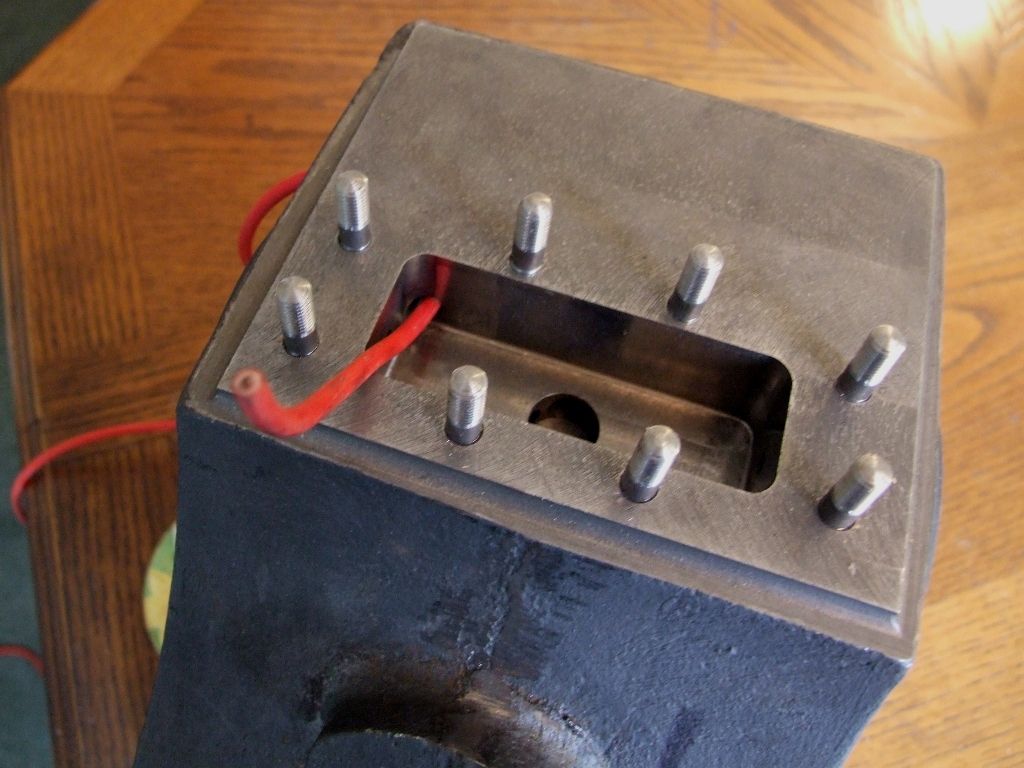

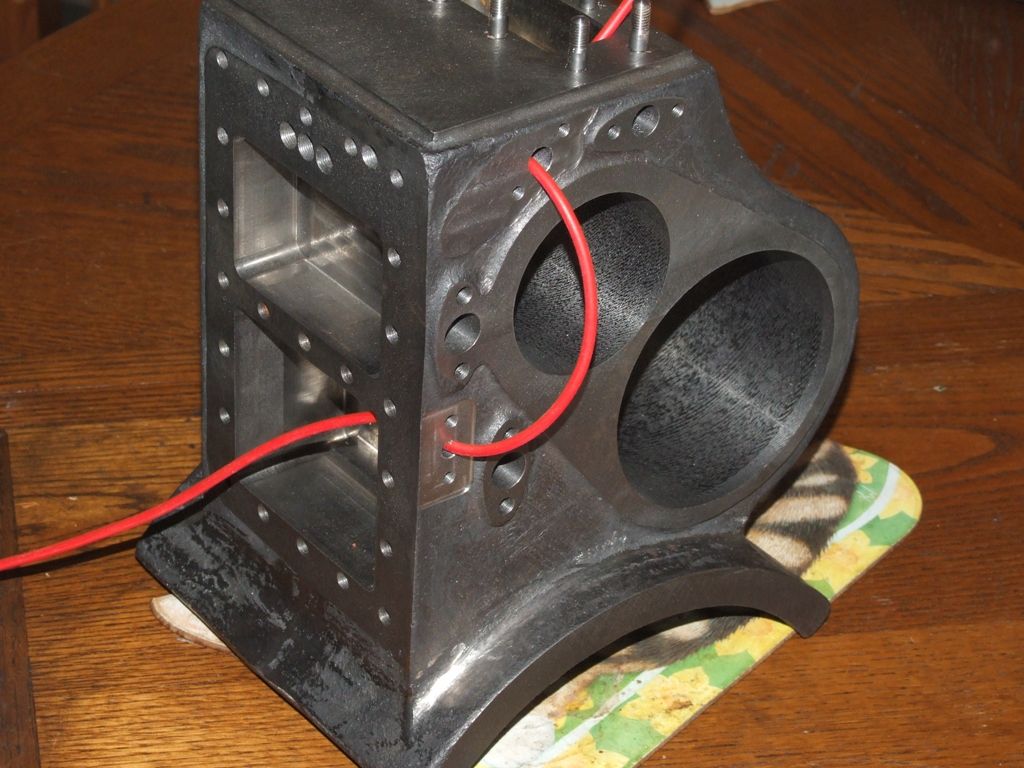

Compound Engine for a Hindley steam-wagon – no drawings available just 100+yo advertising photos, of which several suggest the regulator was an ordinary gate-valve bolted to the boiler top, and one suggests the simpling-valve was on the outside of the HP valve-chest.

Can anyone please tell me how these things are actually meant to work?

I cannot find any general principles for these fittings.

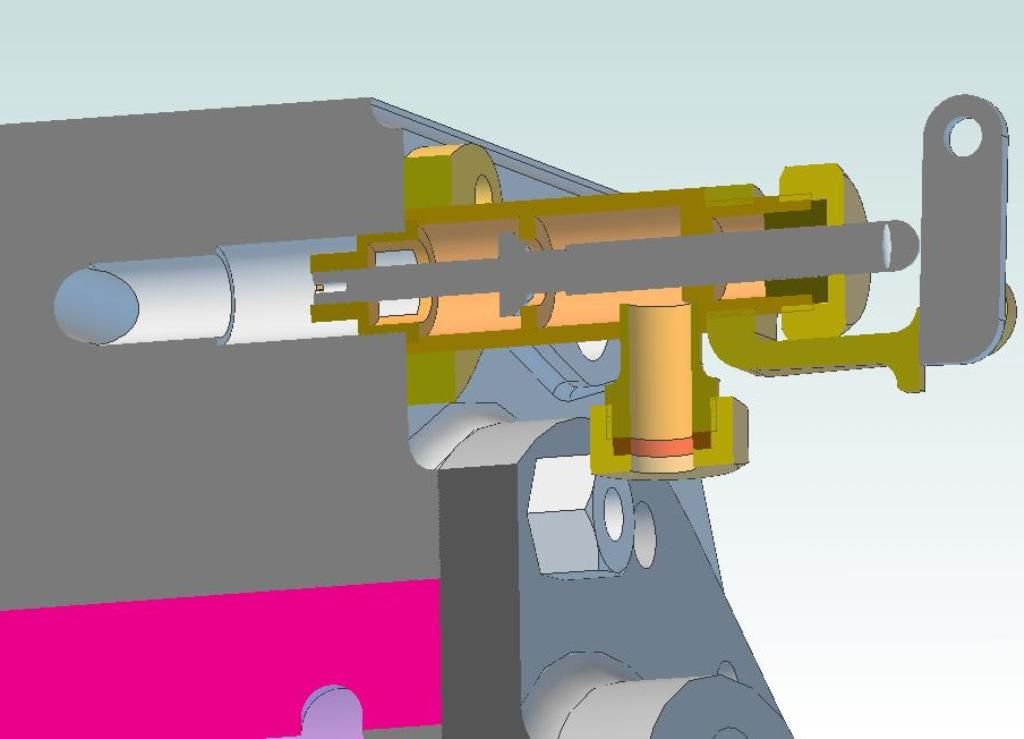

I can find only scant drawings and information suggesting various basic forms. The drawings are only cylinder sections showing complex multi-port plug-cocks within tangles of untraceable cavities and passages in the cylinder casting.

Assuming I have identified the controls correctly, the photo I have suggests the alleged starting-valve is formed in the elbow connecting the live-steam pipe to the valve-chest wall, and may open a take-off / restrictor that dives into the mysterious innards, presumably to the LP valve-chest.

That seems inadequate though.

That alone would theoretically give a double-high setting, but negated by putting live steam back against the HP exhaust. Yet this engine seems to have just this single tappet-valve operated by a short lever, on the outside of the unit. (Unless it is actually the regulator – so why the prominent gate-valve upstream of it?)

There is also a curious fitting on the bottom corner of the HP valve-chest, apparently a valve on a pipe that vanishes round the corner of the engine case. If it is a valve it has no obvious handle or control-link, though might be a drain-cock independent of the linked cylinder-drains.

'

I would expect at least two valves for basic double-high working: one feeding HP steam to both cylinders with a restricted flow to the LP, while the other diverts the HP cylinder's exhaust straight to the main engine exhaust. (The restrictor is necessary for approximately equal piston forces in D-H working.)

By two valves, I mean either literally that, linked by a control-rod, or a single piece of metal amid appropriate ports and passages.

SO….

Whilst I still have some grey hairs, I would be very grateful if someone can tell me the basic layouts of double-high valves.

I know what they do… I need to know how they do it!

Nigel Graham 2.