Ray

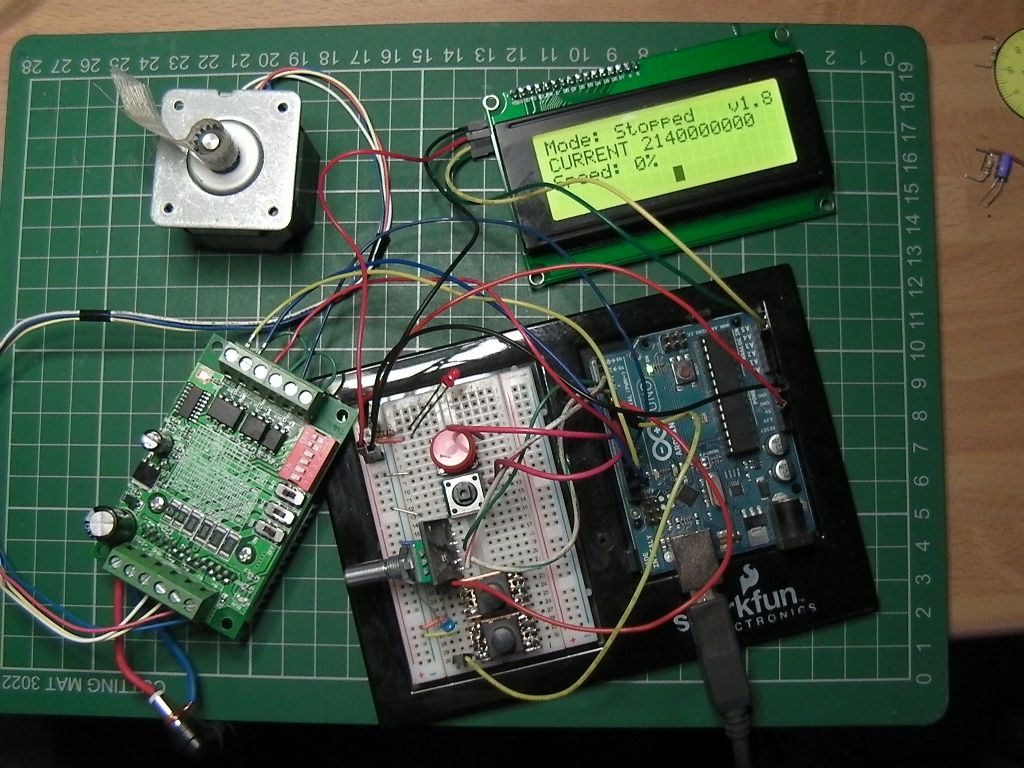

I thought i should add some more information regarding my earlier picture of a rather untidy Arduino Stepper combo.

I wanted to build a power feed using a stepper. I bought a 3A stepper driver for £5.50. It requires 3 incoming signals. Enable=power to the motor (this holds it so it cant be moved) ,Step direction=0v to go one way and +5v to go the other and Step=0v to + 5v and back to 0v to step one step of 200.

MEW issues 118 & 119 show you how to build a power feed using a 555 timer I/C + discrete components. The circuits are all included in the article.

I did consider doing this but i also enjoy writing software and i thought the task would suit the Arduino Uno. The Arduino + LCD display only cost £7.60 so not a big investment. The Arduino IDE uses the 'C' programming language and gives full control of all the Input/output pins of the Arduino. The program can be downloaded easily to the Arduino board and tested tme after time. The software gives flexibilty to add functionality not easily achieved using a 555 timer I/C.

My current unit offers Manual control in either direction + speed control that is remembered for each direction. Sofware setting of end limits, Semi Auto single push button to start automated move between limits at the remembered speed and last Auto moves back and forward at the 2 speeds between limits all day long.

But this is still work in progress. You are welcome to a copy of the Arduino C program. I am quite happy with it's current operation but it needs more bells and whistles.

regards

Steve

.

Tony Jeffery.

available on the web that would make the Arduino board behave as a programmer to program a spare microcontoller of the same type as the one on your arduino board. This method will only work if the Arduino that you have uses a plug in microcontroller.

available on the web that would make the Arduino board behave as a programmer to program a spare microcontoller of the same type as the one on your arduino board. This method will only work if the Arduino that you have uses a plug in microcontroller.