I don't think there's a manufacturing defect, it works the way it's designed to.

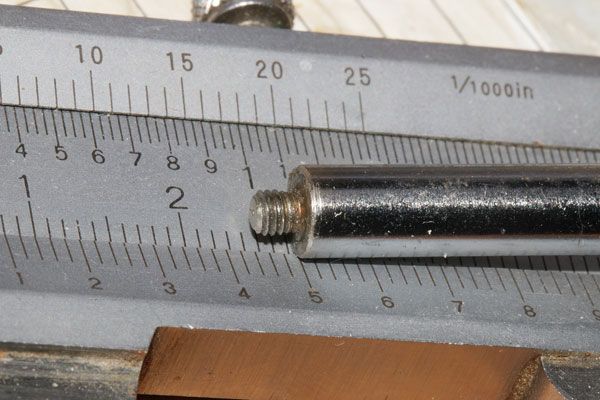

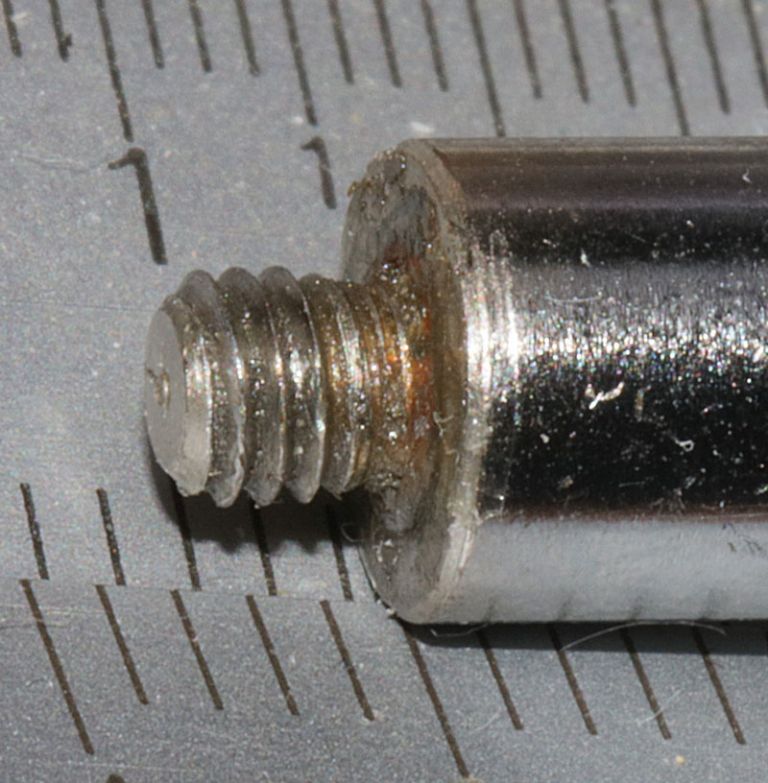

There may be a washer – or perhaps one flat oand one spring washer – missing, but there's precious little thread to put them on as you can see from the close-up.

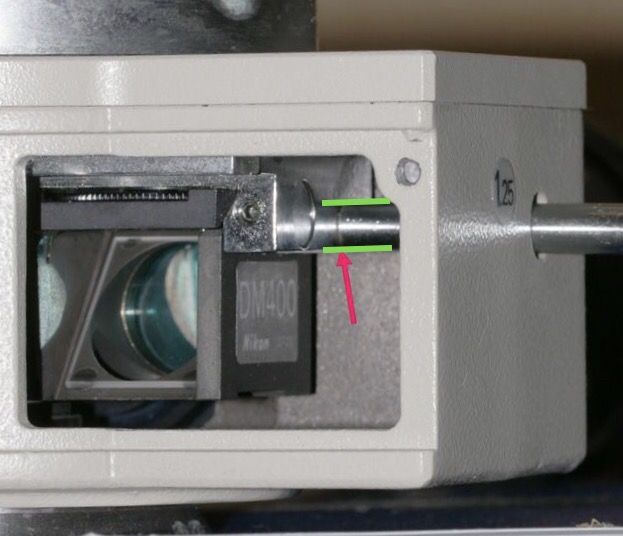

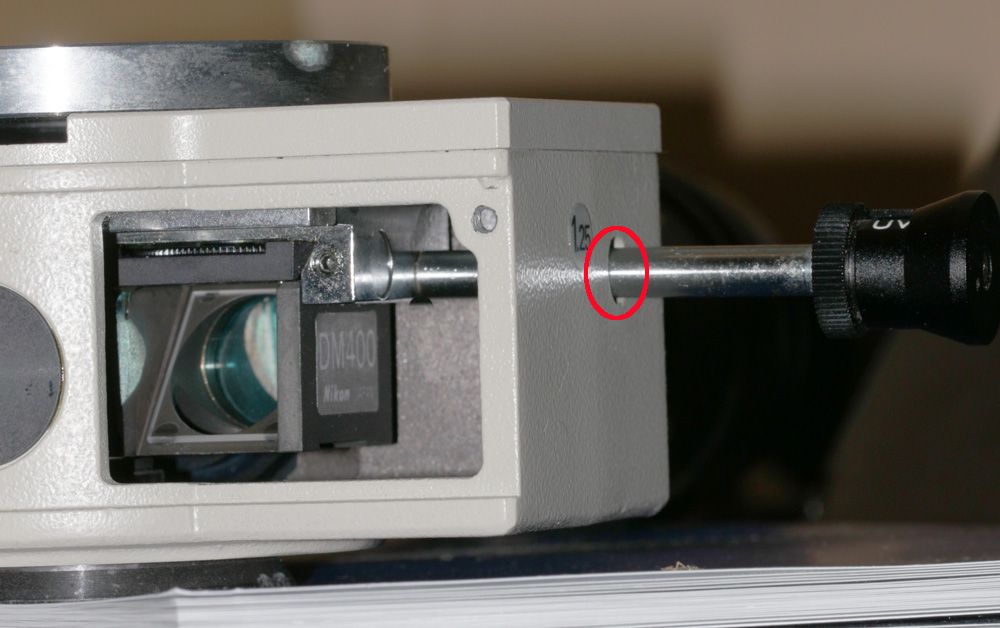

IF the shiny part into which the rod is screwed happens to be parallel to the outside of the box (there's no reason why it should be, with any precision) then I guess I could recentre the hole in the box, drill and tap it maybe 10mm and make a bush, for each rod (there's one each side).

But if that shiny surface is angled then the rod wouldn't stay in the centre of any hole, so things would bend inside when the rod is pulled/pushed. Can't have that.

My foot of 303 has arrived so I'll go that way for now. A slight annoyance is that the rod is not quite straight. Perhaps silver steel would have been ground, I don't know?

One significant contributor to the trauma is the nature of the dried up grease on the cubes' track, which makes them jerky. A dot of WD40 has helped but it'll evaporate.

Microscope greases ("Nye" tend to be very specific and expensive.

tend to be very specific and expensive.

This isn't critical but what type of grease would be light, clean, and long-lasting?

Ta.

Chris R 1.

tend to be very specific and expensive.

tend to be very specific and expensive.