Jelly, thank you for that incredibly generous offer, but I will also say no thank you. I am in West Berks, so Sheffield would be a bit of a stretch.

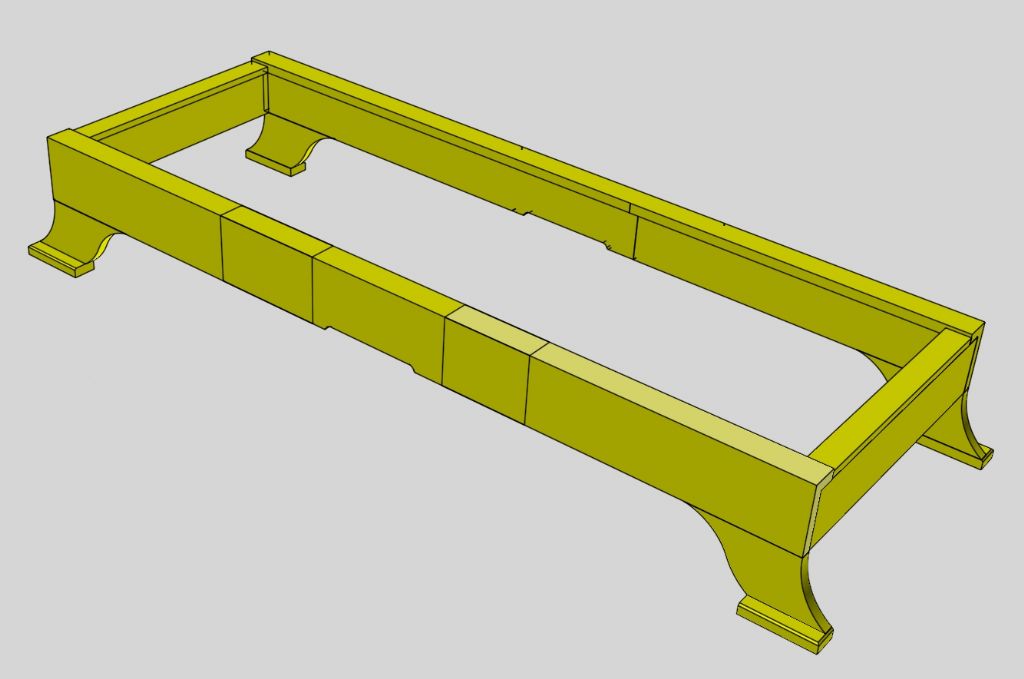

The attraction of making the clock is not the possession of the clock per-se, I have more than enough (40+) of those already, but the challenge of learning to do new and different things to keep my brain active in retirement. There is also, as Jason remarked, the "I made it myself" factor.

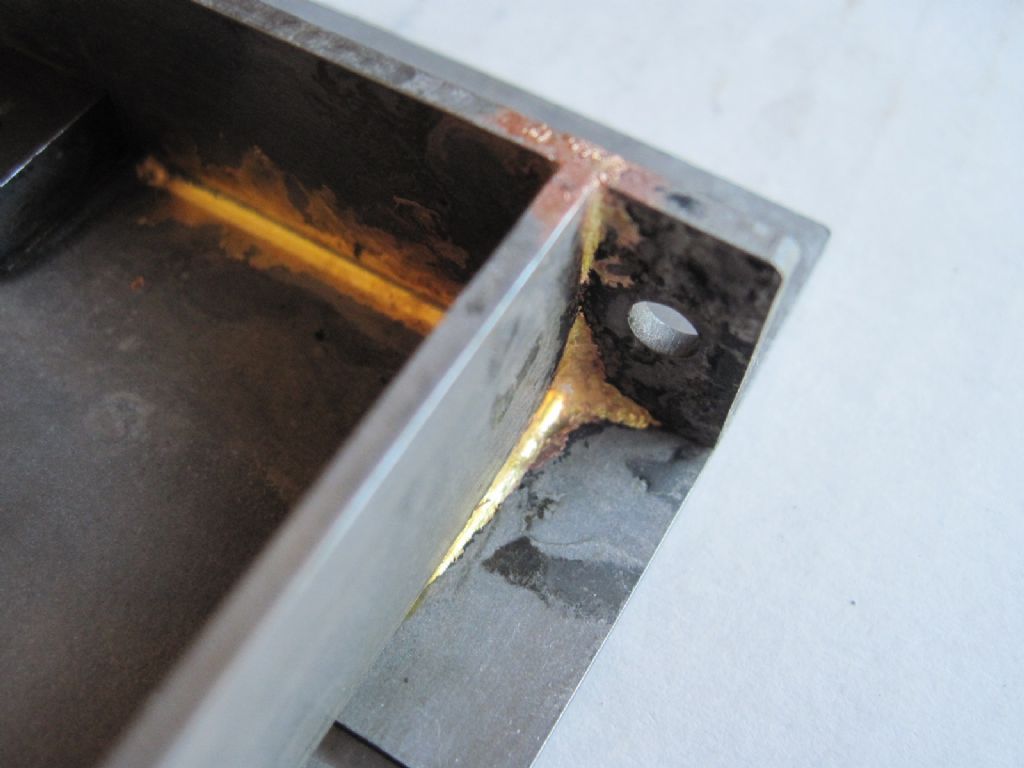

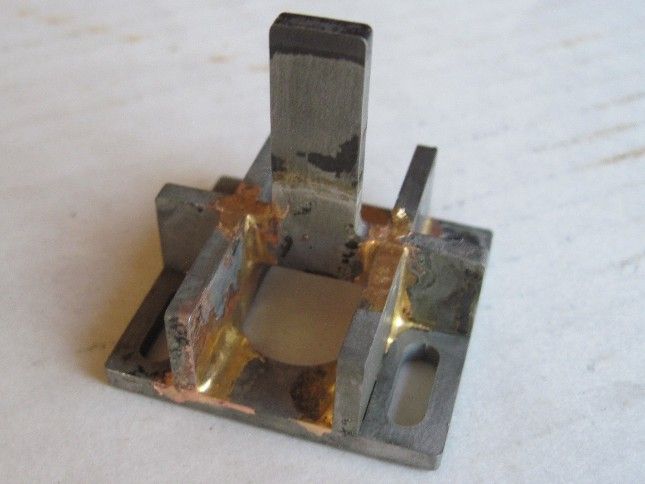

Having taken heed of al the advice so generously given here, I will probably splash out on a decent propane torch, the CuP alloys book and some silver solder and take a swing at learning to silver solder. I might also get some SiF bronze rods and flux to see how that works out.

There are quite a lot of other bits of the clock that are cast, and which I will need to fabricate in some way. Silver soldering may be the answer to those as well. I will probably be back with more questions over the next few years.

Thank you again for the incredibly generous offer, and thanks to all the others who give of their time and experience to answer my questions.

Ramon Wilson.