It is unlikely that there will be a clutch, as such, between mandrel and Leadscrew. More likely a handle that operates the tumbler reverse to allow the feed to be engaged, for Forward, Neutral, or Reverse.

The technique for machining up to shoulder is to have fantastically quick reactions to open the half nuts, just before the tool hits the shoulder!.

The practical and sensible alternative is to stop the machine just before the shoulder and then rotate the Mandrel by hand, either pulling the chuck round by hand, or using a mandrel handle.to bring the tool upto the shoulder, stopping JUST short of it.

Your friend could spend his time well, initially, by making a Mandrel Handle.

It could save him a lot of broken tools and scrapped workpieces.

For a fine feed, with the aim of getting a good surface finish, the Leadscrew needs to be geared down so that it rotates as slowly as possible compared to the chuck. If it needs to be said, a small radius on the nose of the tool will improve surface finish.

The C2 and C3 mini lathes include two 20T gears and 2 x 80T gear, among their changewheld, so a 16:1 reduction is available Probably the C1 does as well.

With a 1.5 mm pitch leadscrew, this will give a feed rate of 0.09375 mm per rev ( 0.00369" per rev in old money)

If the lathe is Imperial, the Leadscrew is likely to be either 8 tpi or 16 tpi.

With a 16 tpi leadscrew this will give a feed rate of 0.00391" per rev.

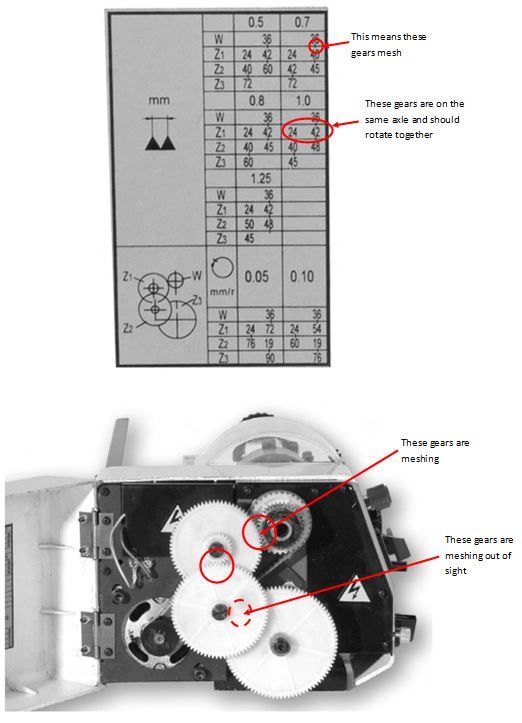

For screw cutting, the changewheels are selected to give the required ratio between Spindle and Leadscrew

So for a 0.5 mm pitch thread, with a 1.5 mm pitch Leadscrew tjhte ratio would need to be 3:1. Probably using a 20T on the Mandrel, and driving via an Idler, to a 60T on the Leadscrew.

To cut a 1 mm pitch thread the ratio would need to be 1.5:1 so probably a 40T driver to a 60T on the Leadscrew , with an Idler to fill the gap between the gears.

If your friend is unsure, he needs to buy a couple of books, for a deeper explanation and examples of set ups.

Martin Cleeve's "Screwcutting in the Lathe" which is No. 3 in the Workshop Practice Series, and Brian Wood's "Gearing of Lathes for Screwcutting" The latter gives table of changewheel set up for a number of lathe, so that probably no calculations would be needed, just set up according to the tables for your particular lathe, or one with a Leadscrew of the same pitch.

Obviously if cutting an Imperial pitch thread on a Metric lathe, or vice versa, ideally a 127T gear would be needed, but a 63T gear will produce threads with acceptable pitch errors,being a it is low powered, so shallow depths of cut will be the order of the day.

The manual for the C2 or C3 regards 0.010" (0.254 mm ) as a roughing cut, although many exceed that figure without problems.

HTH

Howard

Howard Lewis.