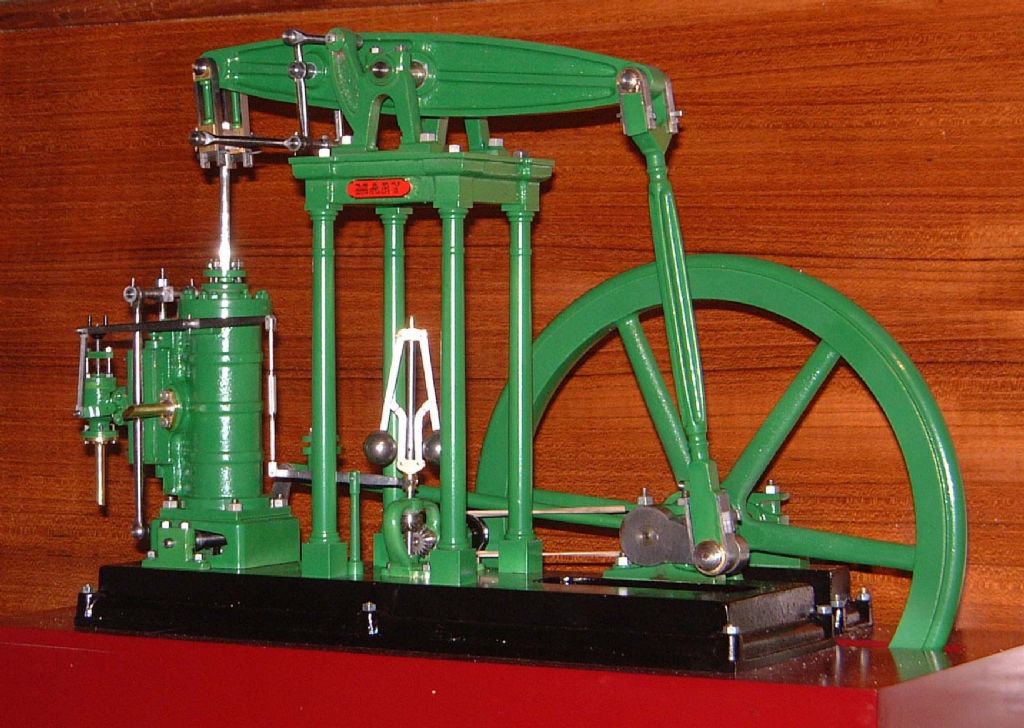

Well I did make a crude beam engine at school but don't have a photo, was not much of a sucess as the aluminium flywheel I cast using a Mamod one as the pattern was never going to carry things round with all the tight spots and air leaks to contend with.

I do still have the square that I made, rivited together from layers of 1.5x20mm steel, still gets used for rough marking out of things like black bar

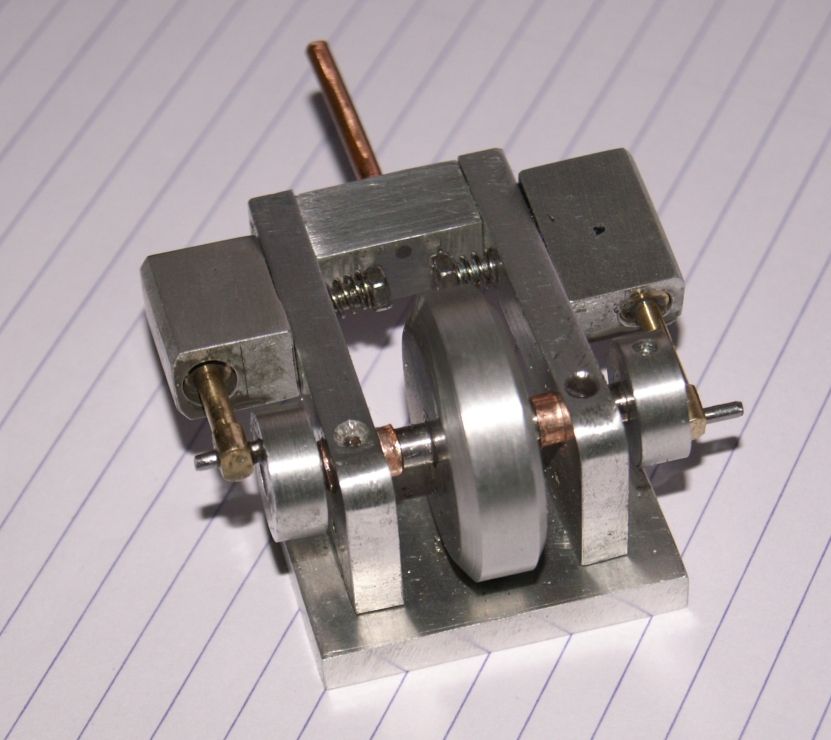

When I was about 15 Dad bought me a Unimat3 and I made several bits for that, the only one that I could find knocking about in the back of a draw was this marking gauge minus it's pianowire point.

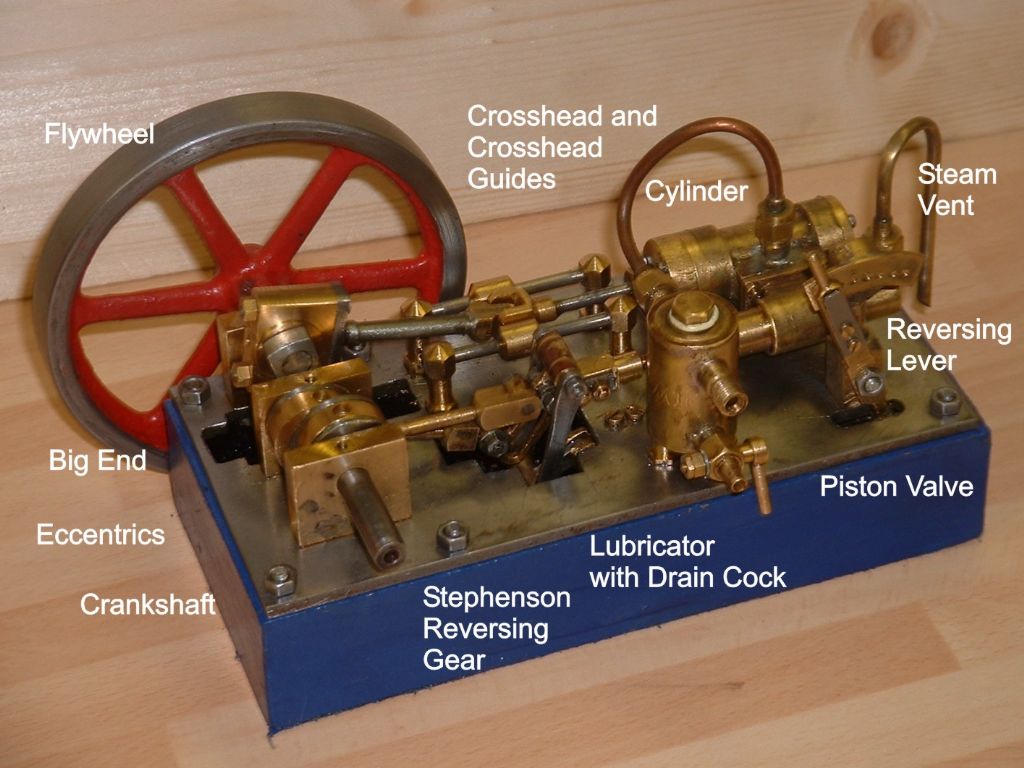

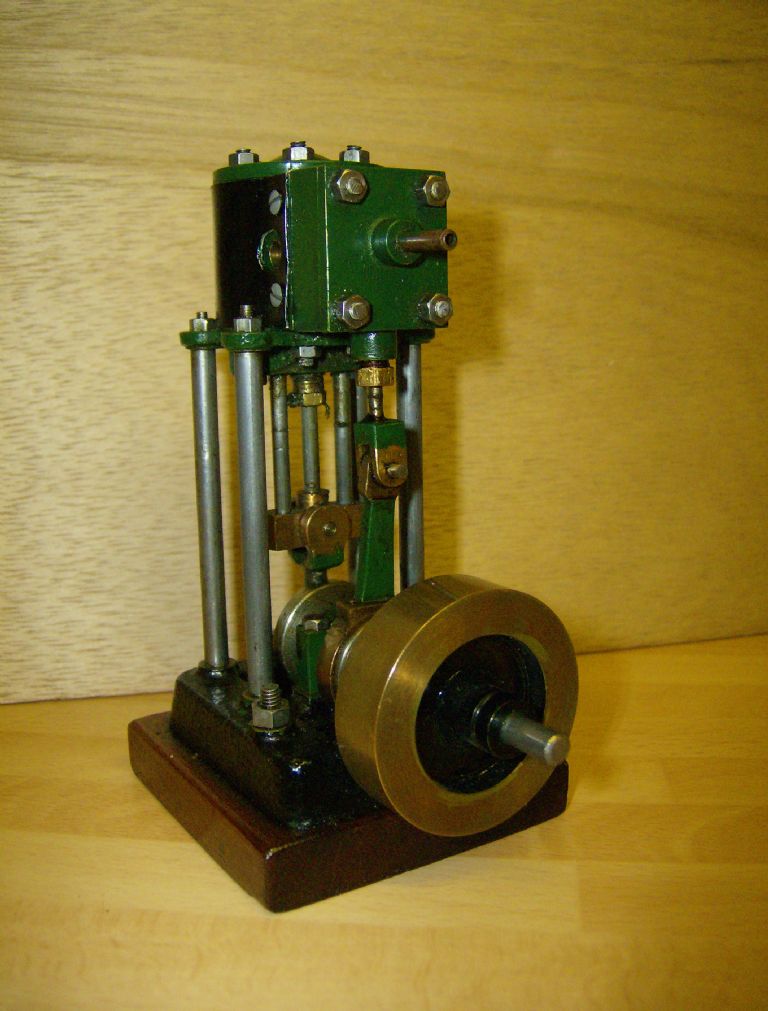

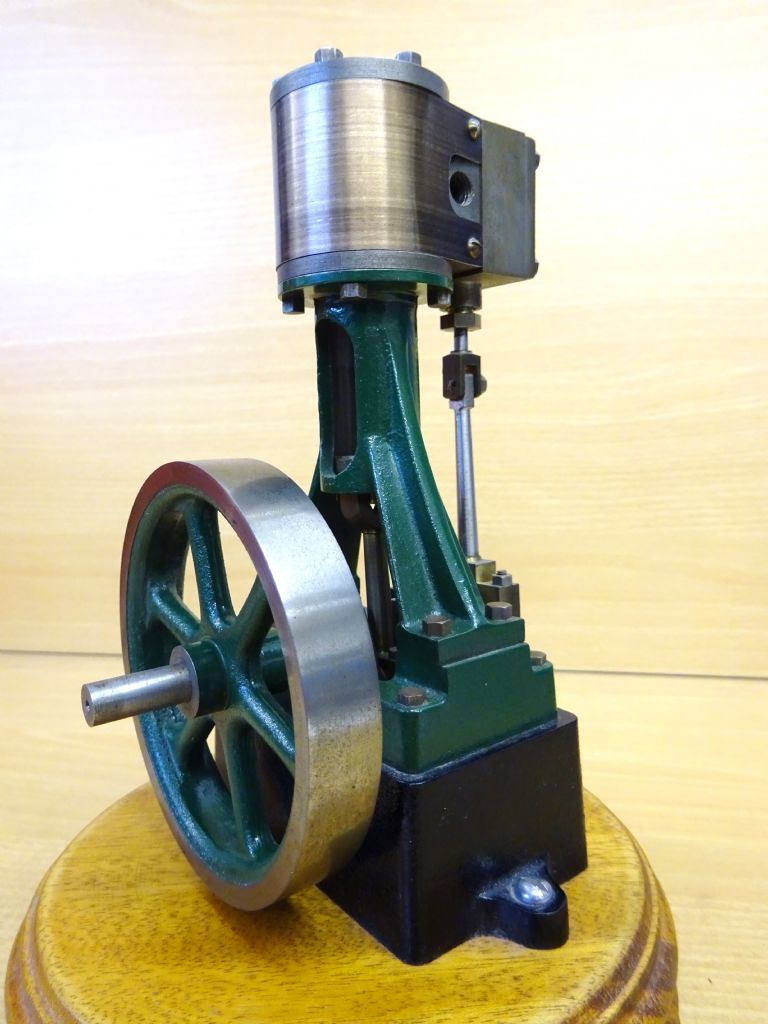

At about 16 or 17 I made a proper engine all on the Unimat 3 in the form of a Stuart 10V, its a bit rough when I look at it closly now but was the best I could manage at the time.

I dusted it off over the weekend and made a connector for the compressor, does not run as slowly as I would like due to quite a big airloss around the piston rod gland as that has to be left very loose if things are not to bind up. I suppose I should remachine the offending bits now but will probably leave as is.

J

daveb.