+1 for a simple lantern chuck.

I just got an M10 bolt with plain shank of about 12mm left once the head was cut off . Get a number of M 10 nuts and solder or silver solder them onto a piece of scrap brass sheet to cover over the front of the nuts. Then screw nut on , mount in chuck, trim the brass plate to diameter , drill and tap whatever size you want and there is your lantern chuck. Unscrew the nut to fit your screw of whatever thread you choose. Helps to mark the nuts with whatever thread they have been tapped – dont ask how I know !

I actually drilled down into the M 10 bolt end and fitted a little copper pad to cover the top of the M 10 thread with a spigot on the back to locate it in the hole, this prevents damage to the screwhead.. Also to help with longer screws, I fit a loose piece of copper of brass bar into the same hole , the right length to accommodate the length of the screw I want remaining inside the chuck. When doing this I find it best to also tighten up a nut on the inside of the lantern chuck facing / securing nut.

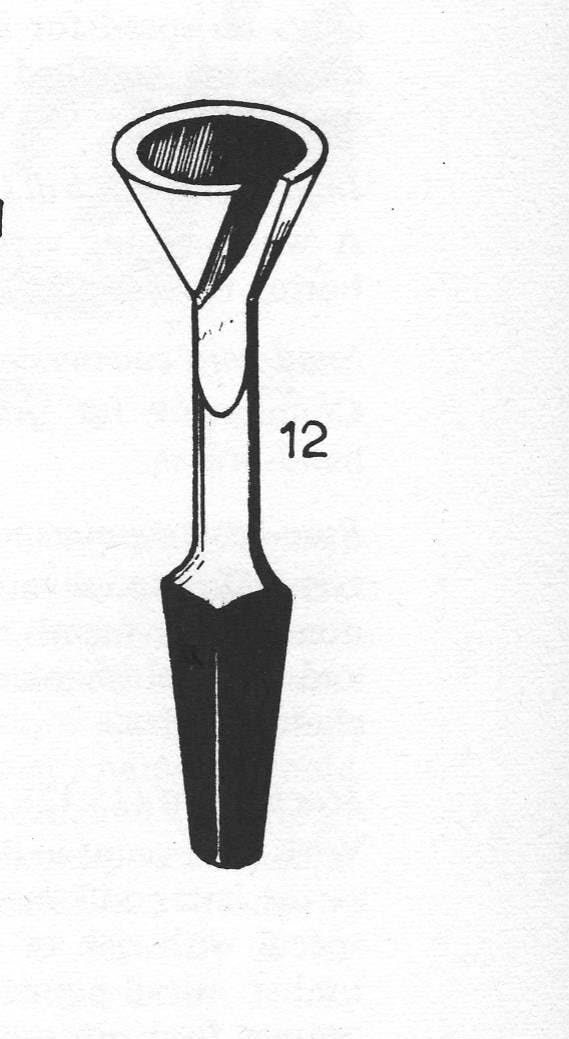

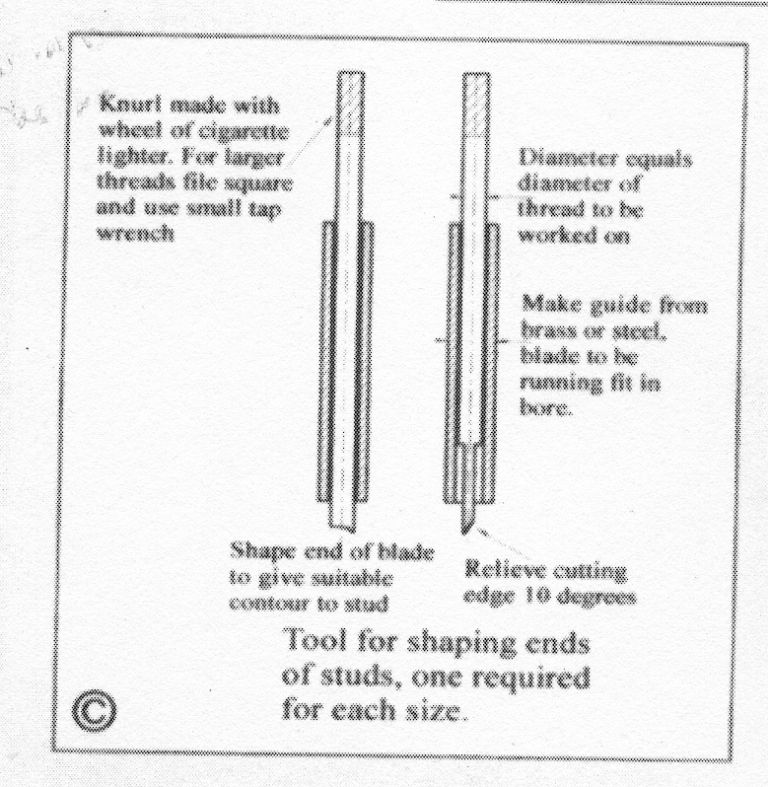

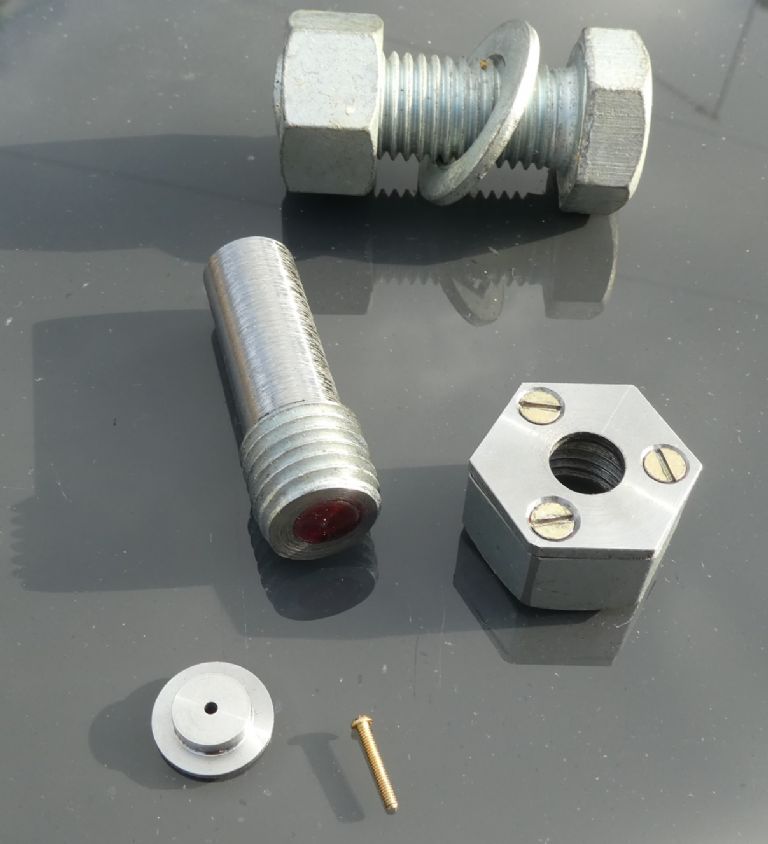

For shortening studs I use a "stud box " A short length of Hex bar say 8mm drilled and tapped through with the thread e.g 6 BA. leave thread tight , I use second taps only. On one end fit a 6 BA bolt and nut. In the other end place your embryo stud. Adjust the bolt and nut to give the exact length of stud you want and lock the nut. Hex bar in lathe and form the end of your stud. Reverse the stud in the stud box and form the other end. " Ditto repeato" This morning I did 20 6 BA x 1/4 long studs in far less time that its taken to type this !!

Happy workshop time All.

Speedy Builder5.