"When you say "towards me" i presume you were standing on the operators side, ie where all the handles and adjustments are. If so, you do in fact have a problem."

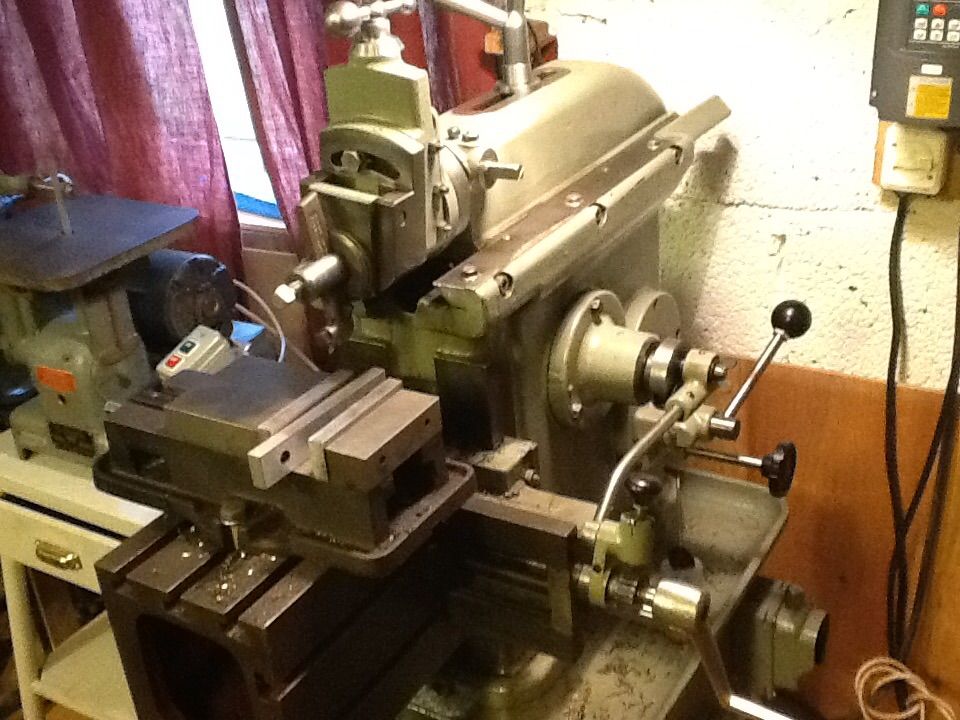

Mike – your presumption is correct and as you rightly point out, I do have a problem. Just to clarify my OP, if I stand in front of the machine facing it, the table is stuck hard over to the right nearest to the winding handle.

Because the machine had been standing idle for many years and despite my attempts at cleaning and lubing, the table was quite tight – but movable – on the cross slide, I have tried pushing it while winding to get it back on the thread but it is far to tight for that.

Next thing I'll try is to loosen the bottom jib and one of the screws on the top jib (the other two are masked by the main casting) and try and give it another push.

While I have been pondering a solution I set the ram going for a little light entertainment and the rotten drive belt snapped !

Do you ever get that feeling that you are being got at?

They say these things happen in three's so just in case I'm wearing an extra pair of underpants.

Rik

Rik Shaw.

Rik Shaw.