Posted by Phil Whitley on 18/12/2016 21:16:35:

Makes my Alba New 1A with swiveling table look like a right bargain at £160 a couple of years ago, like many of them, the vice was missing

Hi phil

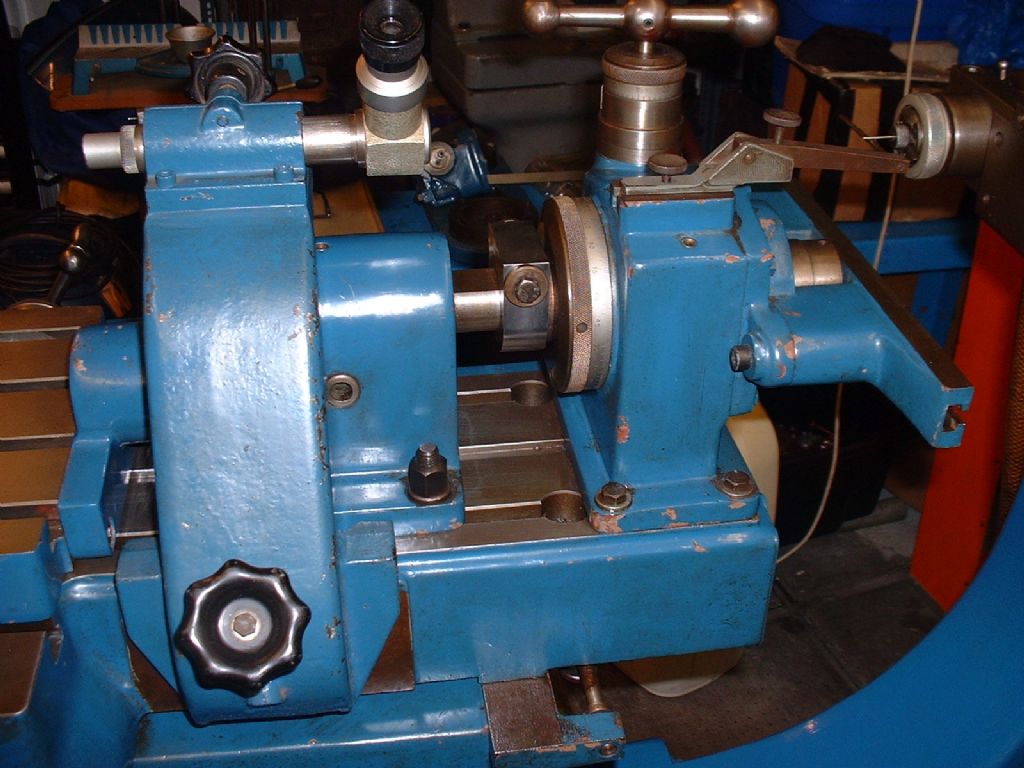

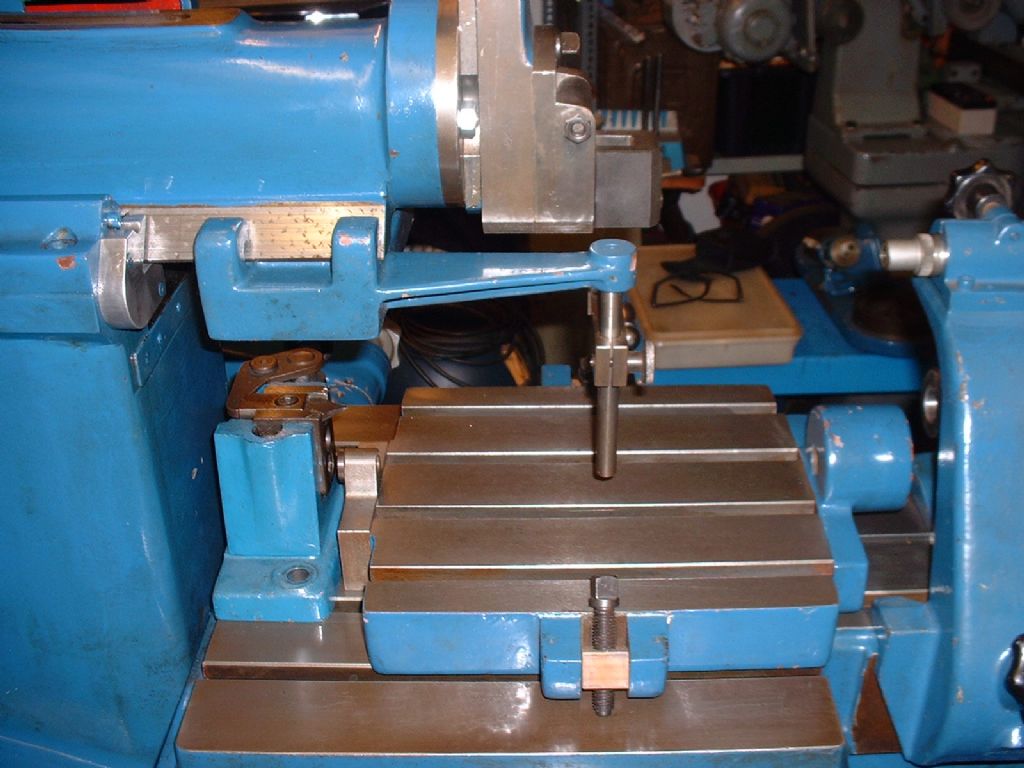

That is about the same price i paid for a mk 1 Royal, ( off a m/c tool dealer ) i did get A vice with it but not a proper shaper vice just a standard milling vice ( not a very pretty one, looked like it had been well pecker"d used as a drill press vice ) minus the the swivel base, so i filled in all the pecker dinks with weld, took most the excess weld off using the shaper in standard mode then resorted to angle grinder fixed to the tool slide to take care off a few really hard bits & a finale skim ( vice base is cast iron weldable but can get a few hard spots usually the size of a match head )

The vice is / was way too big for the table / box, of which i was never too impressed with nothing wrong with it just no where handy to put little bits & piece"s when setting up, so i cannibalized a old land rover engine conversion plate to use as a sub plate on top the box ( sliced off the bit the starter motor bolts to ) The hole in middle of c/plate where the oil seal fits is about the same size as the recess in the underside of the vice, have been using the the oil seal only half way fitted to centre ish the vice will get round to turning up proper boss / spigot some when!

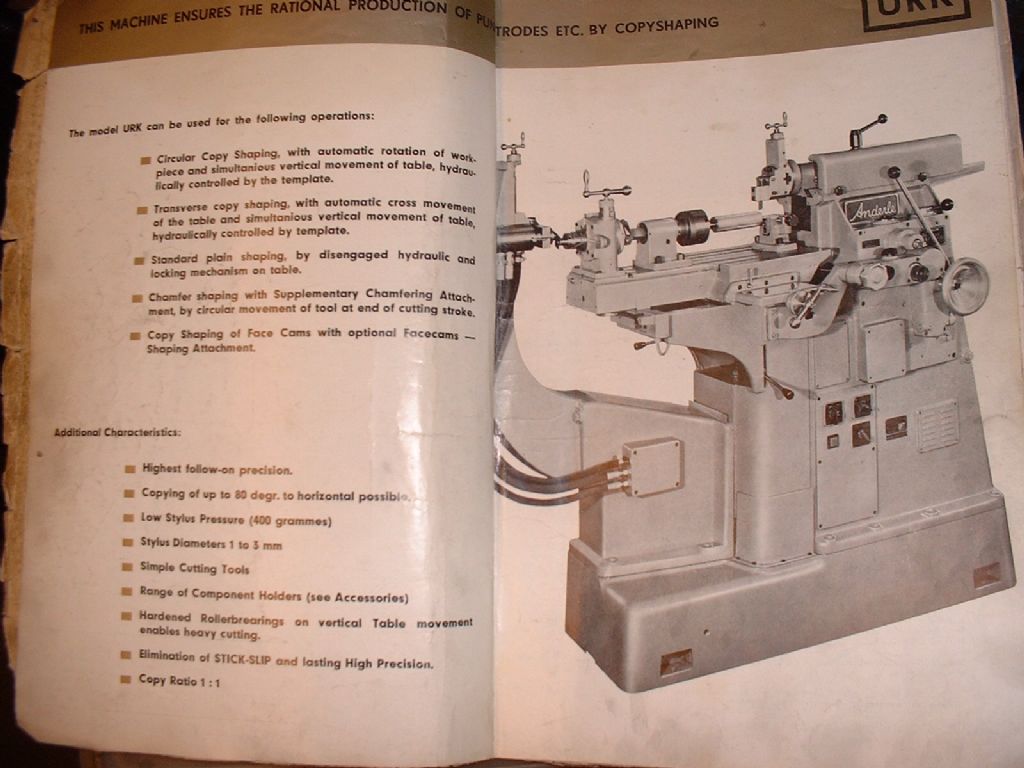

The Royal mk 1 is pretty much the same as the Alba 1a the only difference being the Royal has square shears to the ram where the Alba ( later to become the Elliot 10m ) has dove tail shears ) there are advantages and disadvantages to both, though with the Royal the disadvantage may be more easily over come, cant say for sure as its a work in progress thing, some when!

I have manuals for the 1a and the 10m as far as i can tell the only difference being the 10m has a roller bearing some where in the works and 1a and the Royal have plain bearing, for what its worth i have always thought the terms used in the sales blurb at the time " The new Elliot high speed shaper " to be total BS marking ploy as well as saving a fair few quid by not having to fit the OEM 6 pole motor & jacking the price up with the term "high speed"

The original design speeds for the Alba 1a & Royal mk 1 were 28,36,44,52 of course things things will take a little longer to do but it makes for much more pleasing machine to use, running at these speeds one can mount the machine on a trolley very handy if ones pushed for space

With a few mods a shaper will match the finish & accuracy of a surface grinder…………..b

Mike Poole.

Mike Poole.