Strip-down nearing completion & photos in my album; here are some samples:-

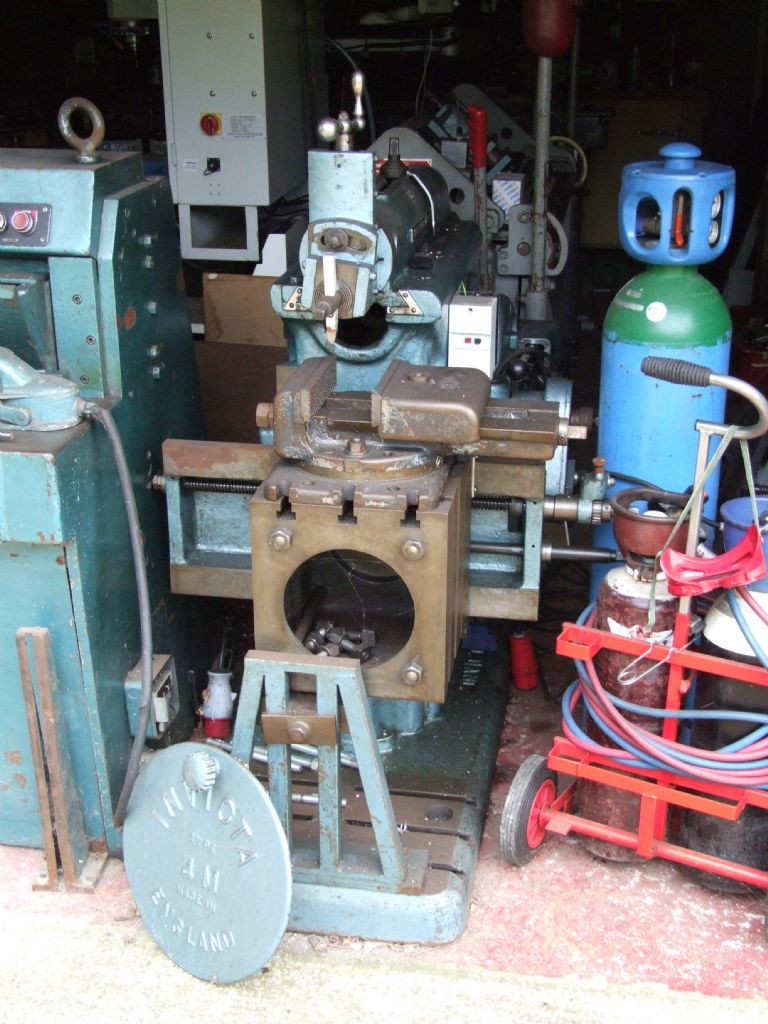

1. As seen & working

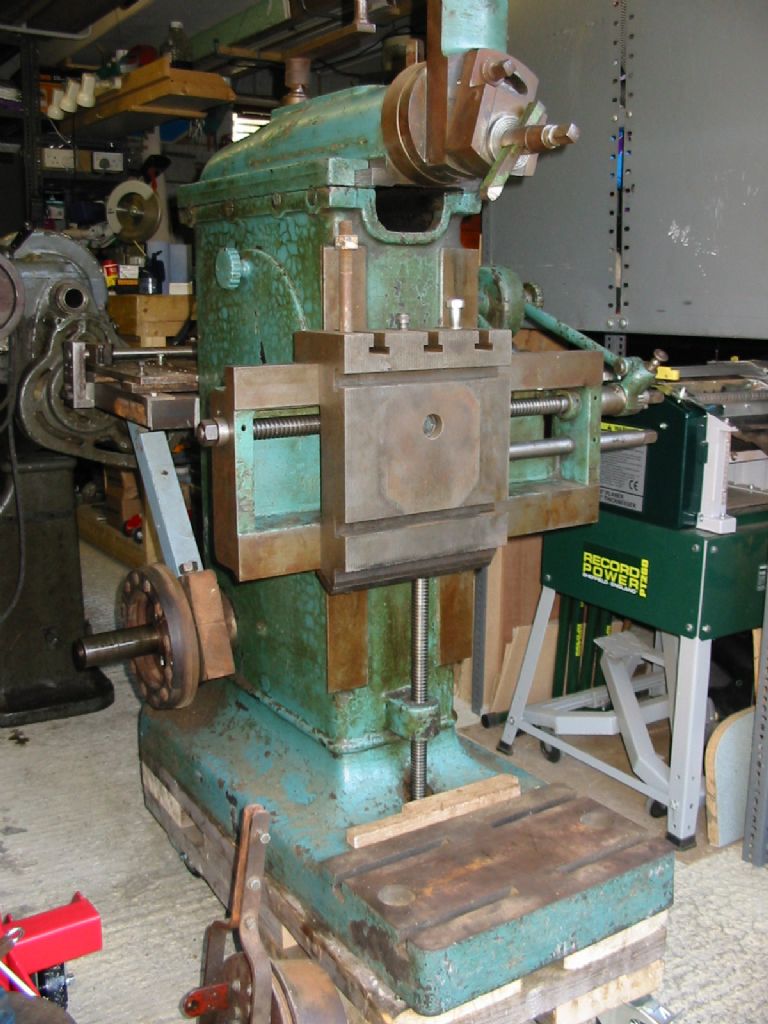

2. Light strip for transport:

3. Fuller strip, LH (clutch opened up; the metre rule is indicating 38" to ram base)

4. Fuller strip, RH:

Things I have discovered so far:- Still no clue to maker. Original colour seesm to have been a light grey – see area behind vice table. Some blowholes in the main casting (none critical). Most theoretically symmetrical mating parts stamped with number (always 1) & do not fit well 180 deg out; poorly-aligned (Whit) boltholes discourage "alternative" fitting. Clutch driving member is an offset, internally coned, spoked, flat belt pulley, now modified with the addition of a plywood, v-belt circumference, outer face bolted through the spokes. The mating driven member is hardwood lined & fixed to the cross-shaft, with separate bronze-bushed bearing housings either side of the main body. From the RHS, drive is taken upwards to the pinion shaft, which is steel running directly in a separate iron housing. Of the 2 flat-belt, 4-step pulleys that came with the m/c but were not fitted, one fits well but the other will not slide fully along the smaller of the 2 shafts – it has a curious lacquer-like finish to the bore that has started to tear with my efforts to test fit it – and there is no obvious way of keying it to the shaft. These pulleys are of slightly different size/weight and the bores are slightly different (not the originals (?)). I intend to fully dismantle the m/c to check the bearings & gear tooth wear and the next step is to invert it to separate the base & main castings and gain access to the bearing at the bottom of the operating arm. I should also apologise for the use of any incorrect terminology as I'm making the part names up as I go along……

My latest thoughts:- 1. Forget about flat-belt drive. 2. Re-con the clutch & fabricate from steel an improved lever operating system. 3. Using the as-supplied motor platform, I estimate v-belt primary drive would be over about 70 cm, with about 8mm of axial motion for clutch operation. Similarly on the other side, re-instate the later v-belt drive to the pinion shaft, junking the 4-step pulleys. 4. Deep breath, install new 3-phase motor & matched inverter.

Questions:-

1. Should I consider modifying the pinion drive housing & make a bronze bush? The shaft surface isn't great, so a light clean-up, bore the housing and turn up a bush seems like a "proper" solution. There again, it's lasted 75 years or more as it is…

2. Between what appears to be cellulose filler under the coats of paint and the iron is a thick-ish shellac-like black layer that isn't susceptible to paint stripper; any ideas?

3. Reference previous discussions: I've gone off the idea of direct drive from motor to pinion shaft with electric "clutching" as too experimental for my situation & capabilities. However, are we in agreement about the layout described in my latest thoughts above?

4. And, of course, any suggestions on parentage would be welcome; we have Butler as a starter for 10…

My thanks in advance, again, for any comments or suggestions.

Adrian

John Olsen.