Thank you Hopper for taking the time to write me such useful information and advice.

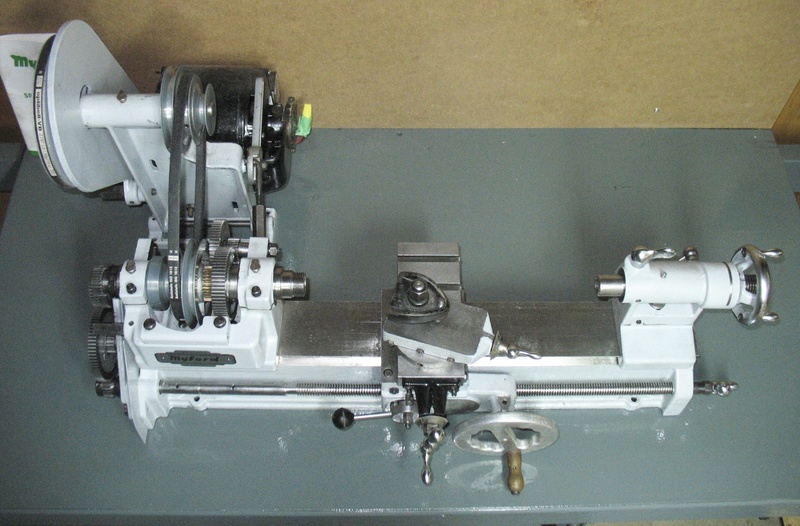

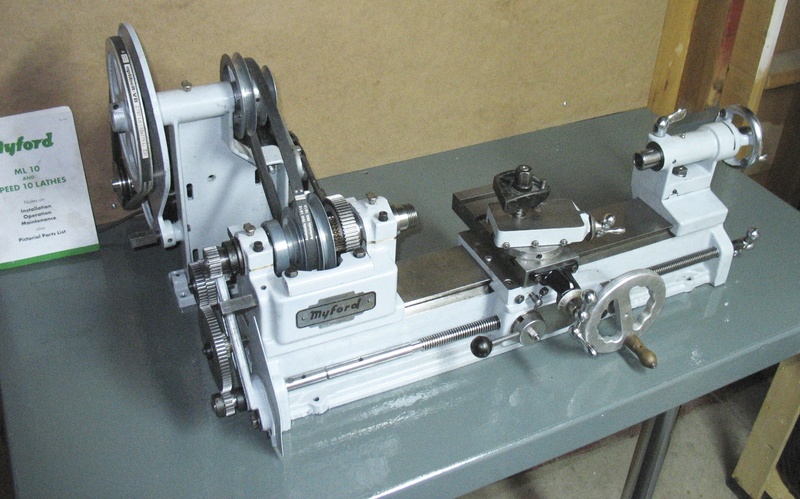

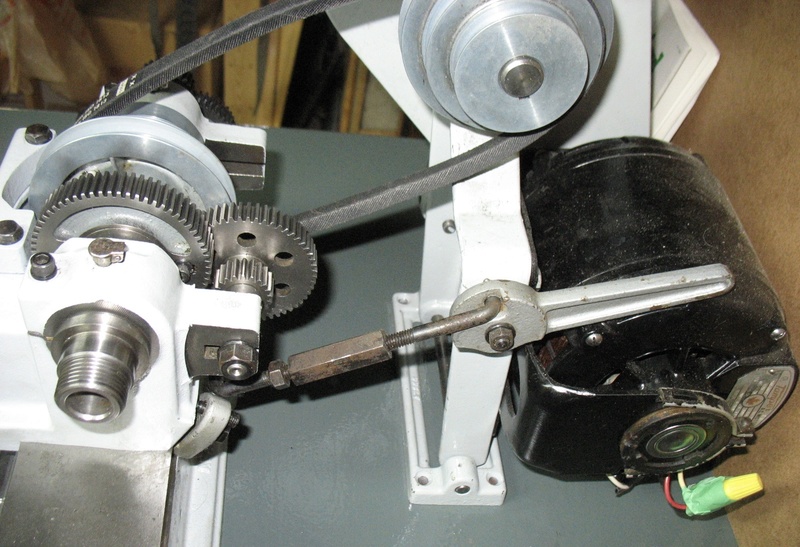

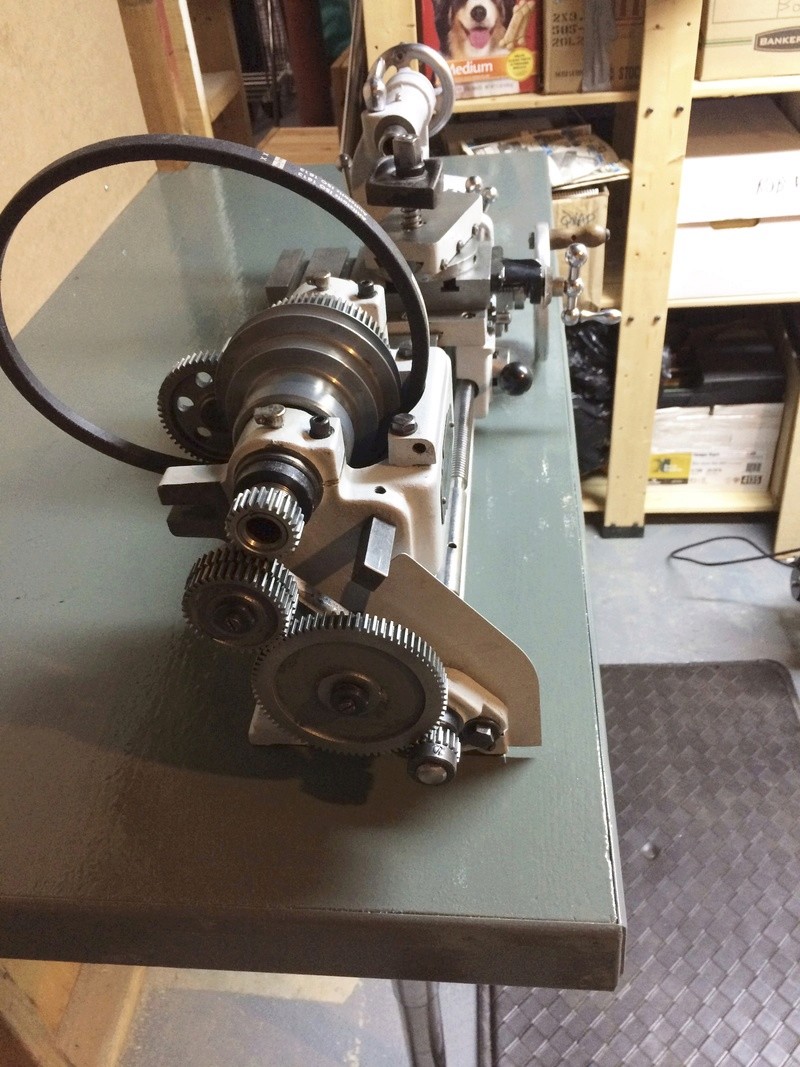

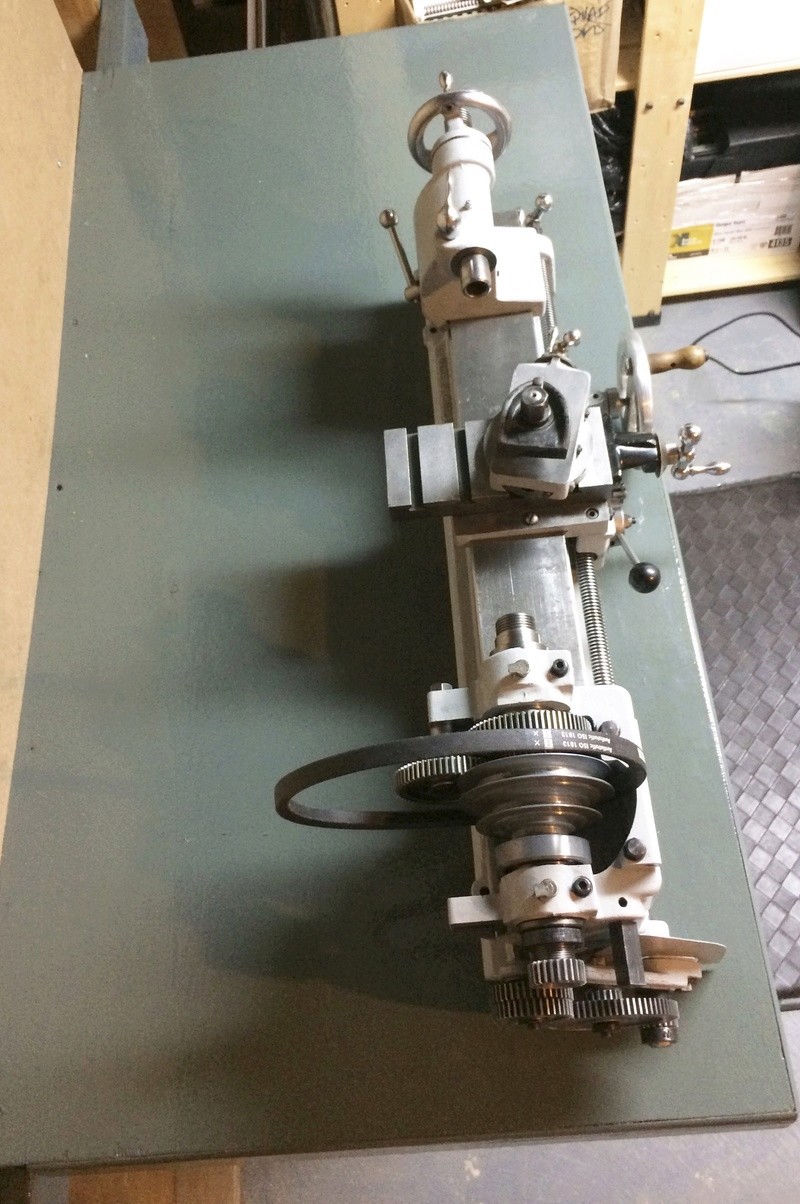

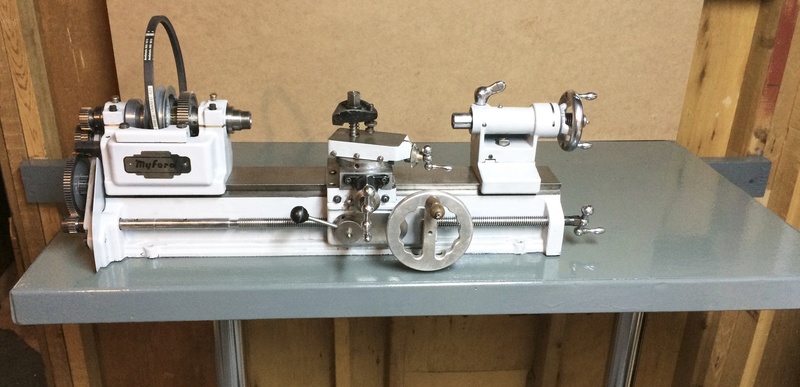

Indeed, I'll need to familiarize myself with the gear arrangement on the left of the headstock, which is setup as I acquired it. I still have a lot to learn about these type of lathes, the only lathe I own is a small swiss watchmaker's lathe, where one works with hand gravers.

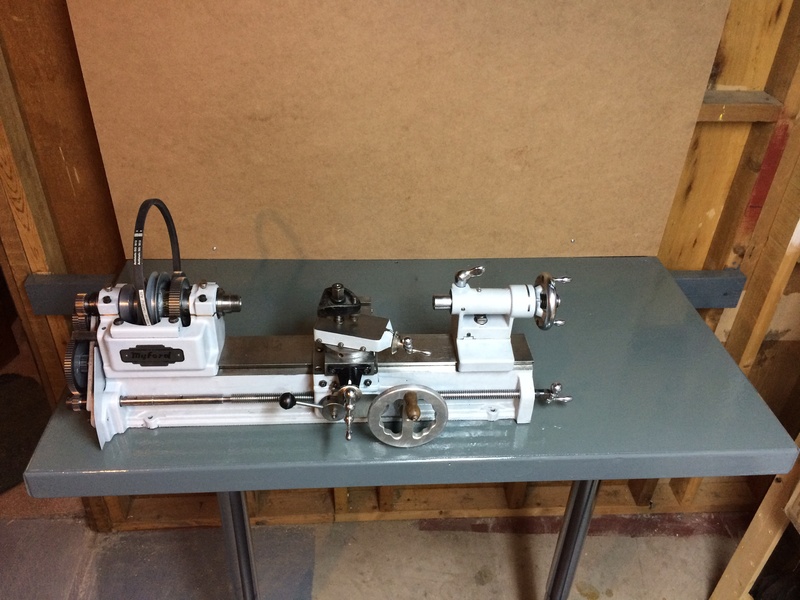

Indeed, it would be good luck to have my lathe mounted on wood blocks and retain accuracy. I've seen videos and read texts about people levelling them with a dial gauge to get maximum accuracy. I'm still not sure how accurate I will need it to be for the kind of work I am envisioning doing with it initially.

As you say, most important for me will be to get it setup and running, and learn as I go along, refining my setup as I progress in my learning path.

When I nailed the wood moulding around the bench to cover the edges of the plywood, I had thought about leaving a bit of a raised portion to catch swarf, and probably should have done so. It's an option for me in the future as you suggest.

Another thing I'll need to figure out is proper wiring of the motor, which according to the guy who sold me the kit is capable of running in both directions. I'll need to get myself a proper switch to start the lathe, and an emergency stop button, to make it safe. Then setup some appropriate overhead lighting, and off I go.

Best regards.

–Robert

Robert St-Louis.