Posted by Ron Laden on 09/05/2020 07:26:10:

Posted by Dr_GMJN on 08/05/2020 10:35:53:

Posted by Ron Laden on 08/05/2020 09:58:40:

Well I had a pleasant surprise, reading above the tramming of the SX2P I thought I would check mine as is quite some time since I did it last and the mill has done a lot of work since.

Y reading across table edge to edge 5.5" = 0.0002" X reading across 4.2." each side of table centre = 0.0008". I don't think I will complain about those readings.

GMJN, one tool I would recommend for your SX2 is the ARC 25mm 2 insert end mill. It takes coated inserts for steel and uncoated for alu etc, it really is excellent I use mine all the time on parts large and small. Great for facing and reducing thickness and the finish it leaves is excellent. Its about the perfect size for the SX2 and the mill doesn't have any issues driving it, very good price to.

Ron

Edited By Ron Laden on 08/05/2020 10:04:47

Thanks Ron – did you try moving the head with your hand while checking the tramming? I'd be interested to see what your thoughts are on any deflections you might get?

No I didn't try moving the head so to answer your question I set the DTI up, centered the table and measured 100mm each side of centre in X. Pressing hard down on each end of the table I had movement of 0.0012" one side and 0.0015" on the other.

I then centered the DTI on the front edge of the table and whilst pressing down on the table I pushed the top of the head back as hard as I was comfortable with. The reading lifted 0.0025" and it was similar dropping 0.0027" when I pulled the head.

I expected there would be movement as it is a small hobby mill but it was better than I thought it would be. Am I worried about it? not at all the machine produces parts to the dimensions I am aiming for and gives a good finish.

Your machine is now trammed just use it, with some half decent tooling it will be fine..

Ron

Thanks Ron, much appreciated.

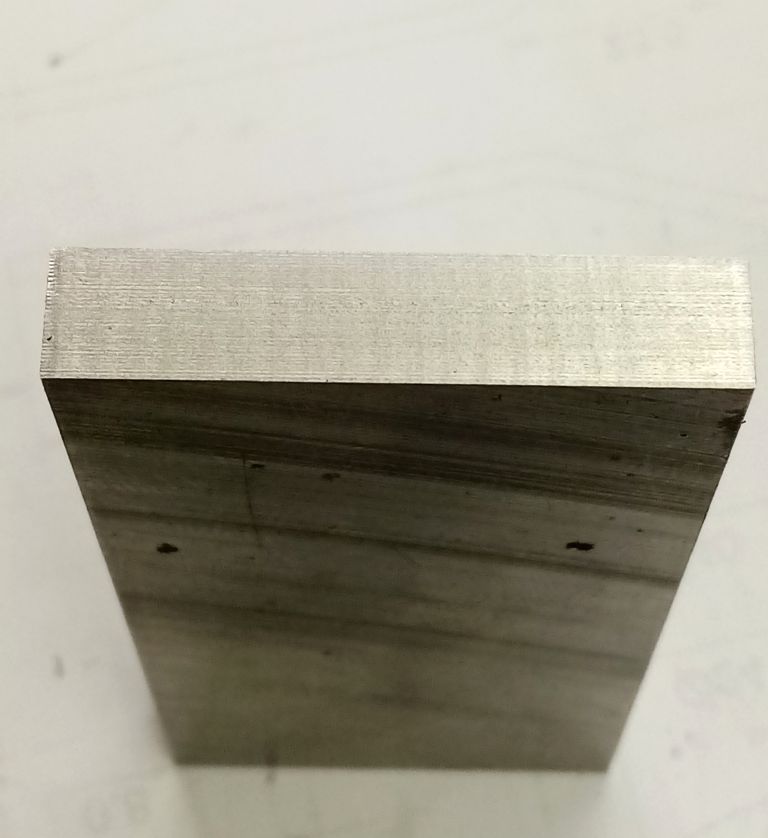

Yes, tomorrow is D-Day in terms of making a start. And make a start I will, although maybe only some preparation on the box base.

I am waiting for delivery of a fly cutter and some new end mills (ass suggested by folks on here) so I'm starting from a known baseline in terms of tooling. Once I'm happy using those, I'll make a start on the machining.

Thor 🇳🇴.

Thor 🇳🇴.