Posted by Antony Cook on 09/07/2009 20:32:10:

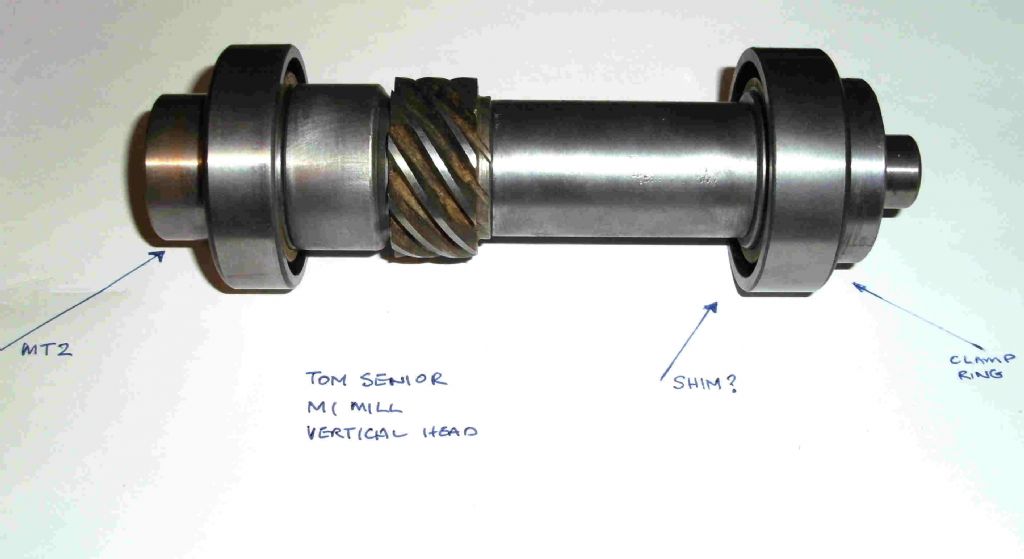

I have a Tom Senior M1 milling machine with a vertical head of the old type. I have had to change the quill bearings and in doing so found a lot of strange things with this head. It seems that there is no positive shoulder for the end bearings (thrust bearings) to rest against, these just resting against the end caps (which were shimmed).

Is there anyone who has changed bearings on one of these heads, and could they eventually be persuaded to make a diagram showing how they were put together? OR is there anyone who is willing to dismantle a head to find out? and make a diagram? I can produce a machine drawing from a diagram which I can afterwards distribute to those who would like this(and to Tony Griffiths of course).

I’ve just come across this post – and last week had exactly the same problem – only perhaps slightly worse. I can confirm that indeed there is nothing in the way of shoulders within the spindle shaft, and that it relies entirely upon the position of the end caps to prevent axial play. And also I can confirm that this total lack of adjustable preload is a pretty poor piece of engineering – almost like an afterthought on what is hopefully (when I’ve rebuilt it) quite a chunky small mill.

In fact, I’ve still got the head in pieces, as I am also contemplating what to do about it. The difference with mine is that there were/are no shims at all – it appears to be just a carefully made fit. To be fair, I couldn’t detect any play – but there again, this particular example hasn’t been run for a very long time, and I wasn’t running the head. The mill was only used as a horizontal, and not very much, by the look of it; the rest of it’s in pretty good condition considering that it’s an early one. It’s currently completely in bits awaiting restoration.

I should perhaps add, whilst I’m rambling on about it, that the reason that I took the head specifically to bits was because there was a small (Clarkson I think, but I’m not entirely sure because it was slightly weird) collet chuck jammed rather firmly in the M2 taper. I ended up taking the whole thing to bits just so that I could support the spindle shaft itself without damaging the casting whilst removing it (this took a couple of hours, and I’ve never had anything jammed quite as firmly as that before). If I can ever get this thing sorted out properly, I intend to replace this with an ER32 chuck instead.

If it’s any help, over the next couple of weeks I can take pictures of what I’ve got, which will at least confirm the current build state of yours.

Edited By Steve Garnett on 16/12/2009 00:08:10

Steve Garnett.