Hi, Old Mart…..I do not fully understand how you did exactly the following…

I bought a steel threaded bar from farm workshop 16mm same thread as original toolbar(I determined the olenght to accommodate all, hacksaw it off). At the top I added a long nut and lock it with a short nut just like you, in my case those go down in the spindle hole no problem. However I can only insert the bar from the top, its too long from the bottom, so if I want to copy what you did, I must hacksaw a short piece of drawbar, screw Bronze Nut on it, then position it with loctite into the spindle, then unscrew that, and screw the drawbar from the top.

1-Where exactly you cut the threads blank…I am not sure how you exactly went about this…

—-In my case I think I dont need to cut threads blank…….? Its 16mm right through.

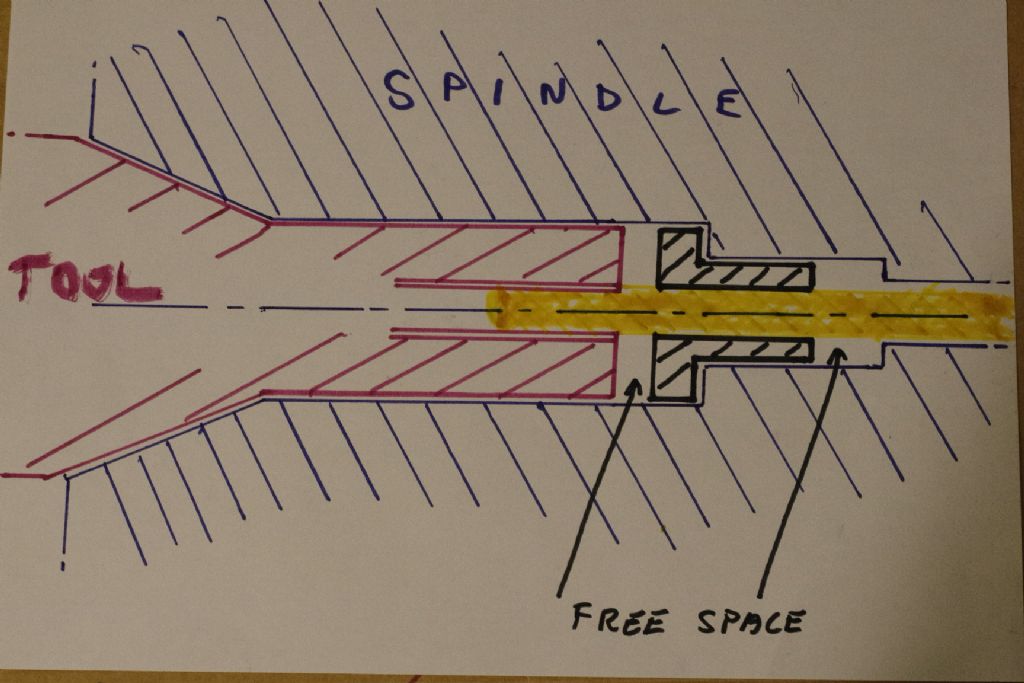

2-I assume your drawbar screw from the top through the Bronze Nut with a space as indicated into the in my case MT4 tool and you can tighten lock it as usual. If you unscrew the drawbar the pressure is in the treads of the Bronze nut forcing out the MT4 tool in my case….?

Thankyou

Chris

Qwote:

Some measuring will be necessary before any work is carried out.

I cut the thread on the 7/16" -(11.11mm)-en 19T drawbar blank on the lathe, and put about 2 1/2" -(50.8mm)-on either end.

I made the bronze nut (in black) long enough to Loctite securely with a flange thick enough to not be in any danger of breaking off.

Chris Mate.