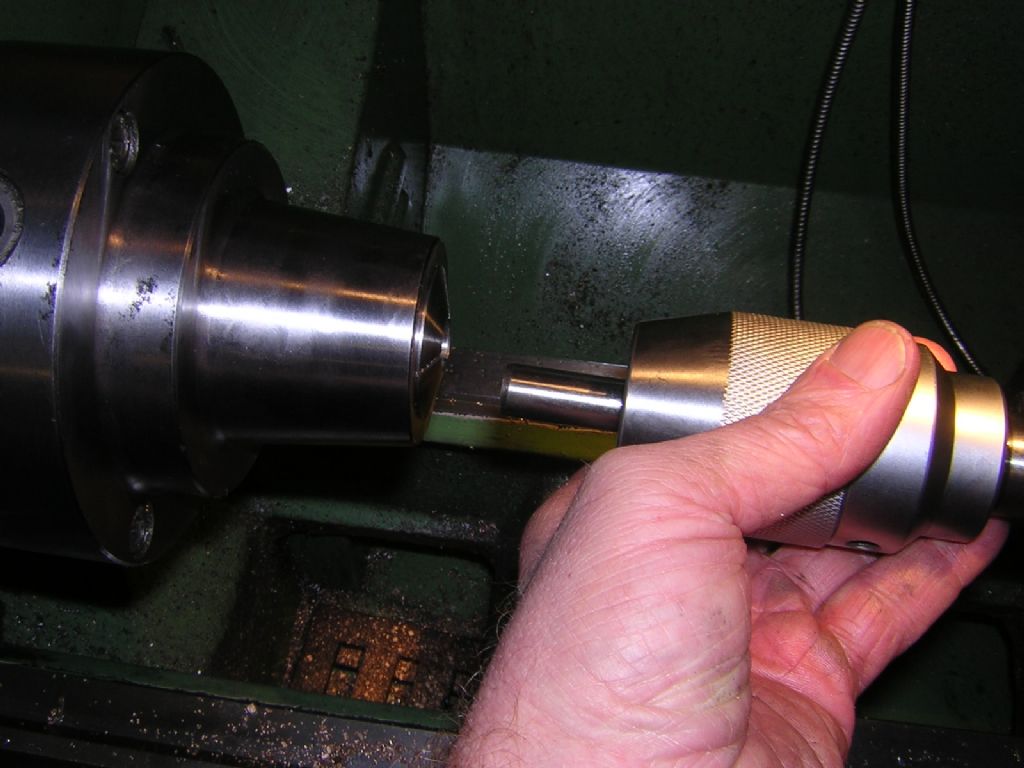

I did the tang to drawbar mod today. I had a nice chuck with integral MT3 taper mount (integral as it uses less headspace in the mill) but wanted the security of a drawbar. So, with JS's suggestion above, and having read an article by Tubal Cain (Tom Walshaw) I set to. I elected to hold the chuck using a dowel held in the chuck's own jaws and a collet in the lathe:

Using a centre in the tang end, I turned a parallel section at the small end of the taper:

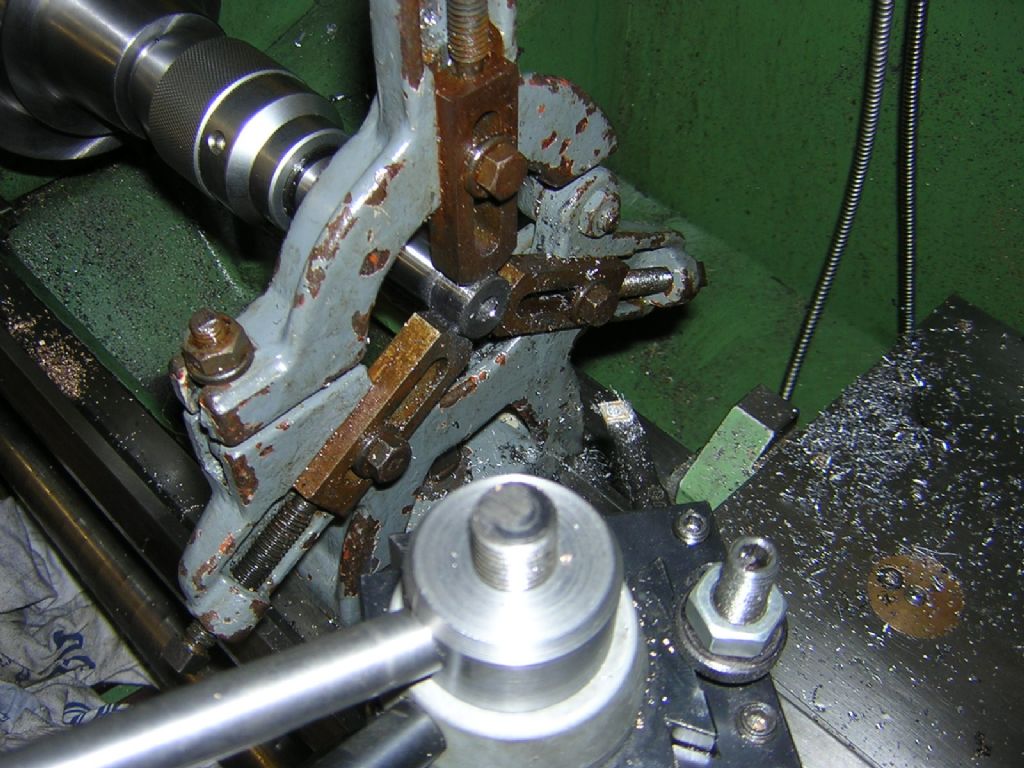

With the centre still in place, I set up the fixed steady on the turned portion of the shank:

I then took the chuck out and cut off the tang. I found that the tang was quite hard – a file skidded off it, but a cutting disc in a Dremel lookalike got through:

Then it was just a question of using a carbide tipped tool to gently turn down the end, drill – again, I started with carbide, but eventually reached softer metal – and tap for the drawbar. Except I didn't have a 3/8 whit tap……so that is a job for another day!

However, the method of holding the tang for machining, using its own chuck, worked well. The tang end was harder than I expected though, and i ended up grinding some of the metal away. In hindsight perhaps i should have cut more of the tang off in the first place using the disc.

regards,

John

Edited By John Corden on 05/03/2014 19:55:35

Edited By John Corden on 05/03/2014 19:56:03

John C.