Posted by Vic on 12/02/2021 21:30:07:

Posted by IanT on 12/02/2021 14:52:14:I

I'm not sure how accurate this would be in practice though. Probably in the "near enough" category for most things I would think but I don't know for sure. I guess I'll have to test it now…

Regards,

IanT

let me know if you do …

OK then Vic here we go

Warning ! – I am not a Metrologist (and those here who are will probably faint with horror) but this is what I did to test it.

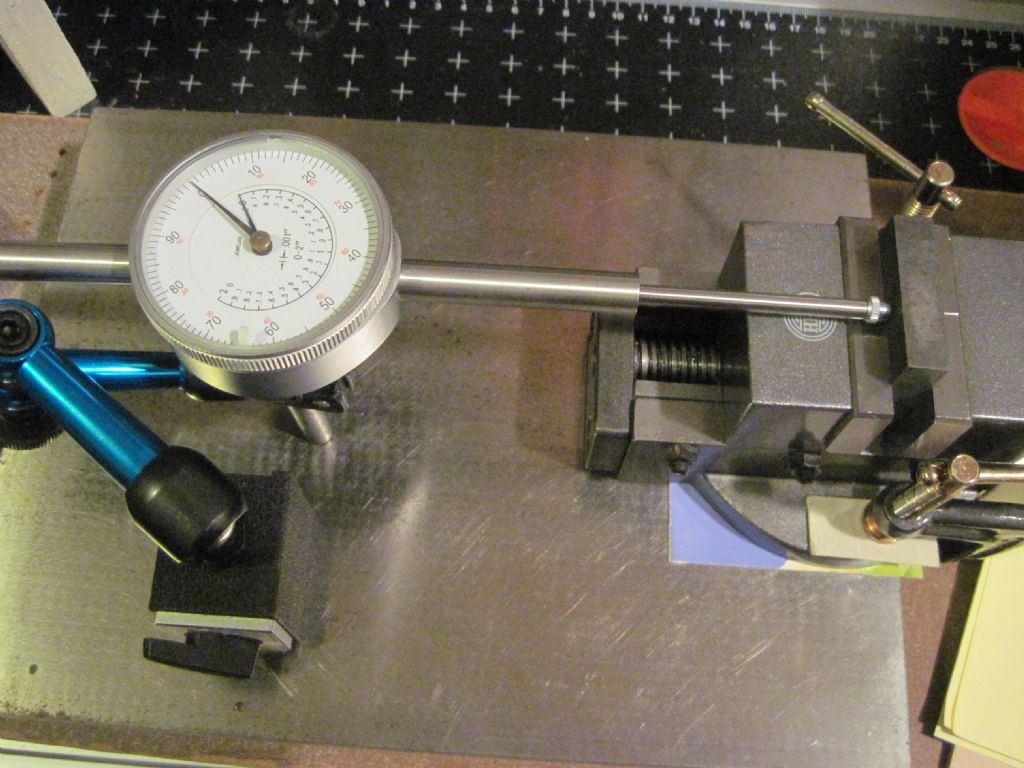

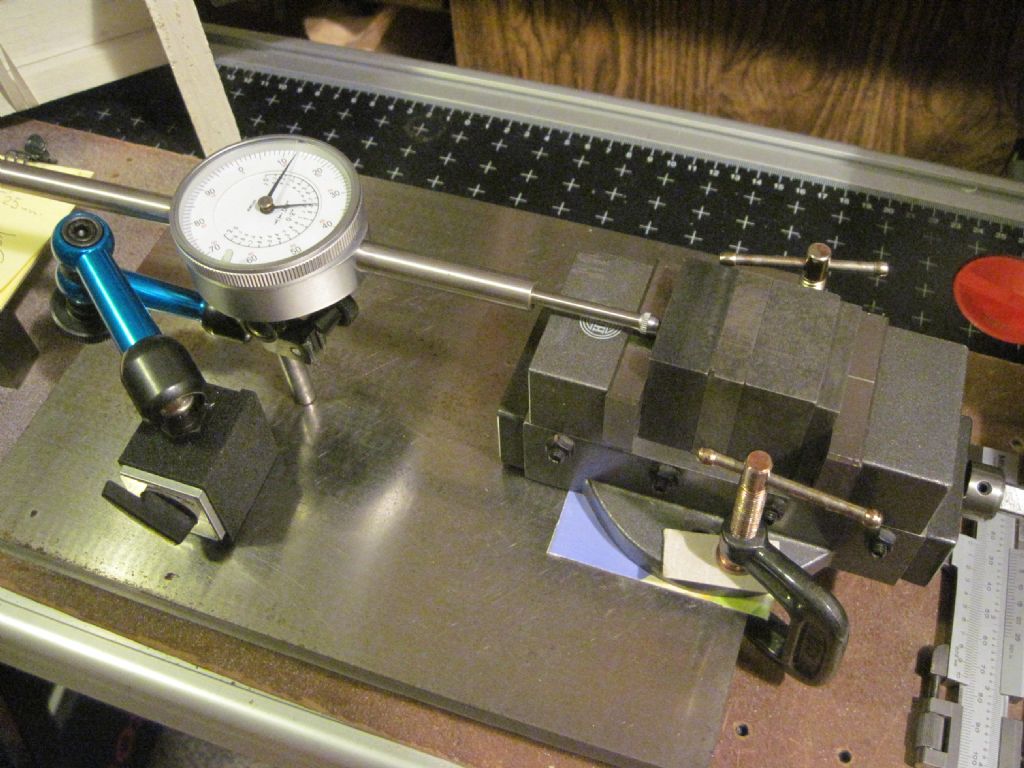

I clamped the vice to the edge of my small workshop surface plate (now well over 20 years old and showing it) and set up a long reach 2" Dial (Imperial) Gauge with a 3/8th packing piece clamped in the vice. I was in two minds on the wisdom of using my Jo Blocks (in a vice?) for this job but the gap at the bottom of the vice was too large for them to sit squarely and that decided me (so they stayed in their box). I have some fairly accurate (but not very pretty) packing blocks that I use (obviously) to pack things 'up' with by a known amount. These seemed good enough for this use…and I didn't mind sticking them in the vice either…

With the dial zero'd on 3/8th (0.375) I added a 5/8th (0.625) and took a reading, then added a 1/2" block before adding finally going to 2". The vice can fully open to about 2.2" .

I then reversed the process, taking readings as I removed blocks. In all cases the vice was slightly 'over-opened' and then tightened back up on the packing, such that any backlash was taken up.

This is what I found:

Packing Reading-Up Reading-Back Calculated

0.375 0.00 -0.0008 0

1.000 0.3115 0.3105 0.3125

1.500 0.5605 0.5605 0.5625

2.000 0.8128 0.8128 0.8125

To explain, the readings are referenced to the zero setting, so are off-set from the centre by 0.1875 initially (half of 0.375). Taking half of the packing size and subtracting 0.1875 will give the 'calculated' number. There are clearly all sorts of things that can effect the readings taken (and note that the dial did not return to zero) but for a relatively inexpensive vice, I don't think it is too bad. Certainly in the "near enough" class for most things I'd use it for I think… which doesn't include CNC by the way.

So I hope that's useful Vic. I'm sure I've screwed something up (or forgotten something key) – I usually do but bear with me, I'm trying my best…

Regards,

IanT

PS The Vice is the 2" HBM branded one, commonly available from your favourite UK Supplier with a rotary base but my base had gone AWOL before it came to me in "used" condition – although it seems it's previous owner was kind to it.

Edited By IanT on 14/02/2021 17:47:38

IanT.