Thank you Dave.

I am afraid it still doesn't work.

I can assure you I was doing my best not to jump ahead. Your outline of assembling parts into the whole thing show that is far more advanced than I have reached.

I followed the second tutorial I had found (the first was the mystery micrometer) and managed to complete its first exercise, a simple L-shaped journal. The tutorial sort of suggested the exercises progress from there, using that journal.

Even with that I discovered SolidEdge is not all it seems because the instructions do not always match what appears on the screen.

So I set out to try the next exercise in the sequence; but it opened a third set! The journal's companion exercises had gone the way of the micrometer.

I picked what appeared the simplest – using a prepared drawing to show how to copy and move objects, which I had naturally thought among the major, most basic features in any CAD programme. Well, useful ones, perhaps.

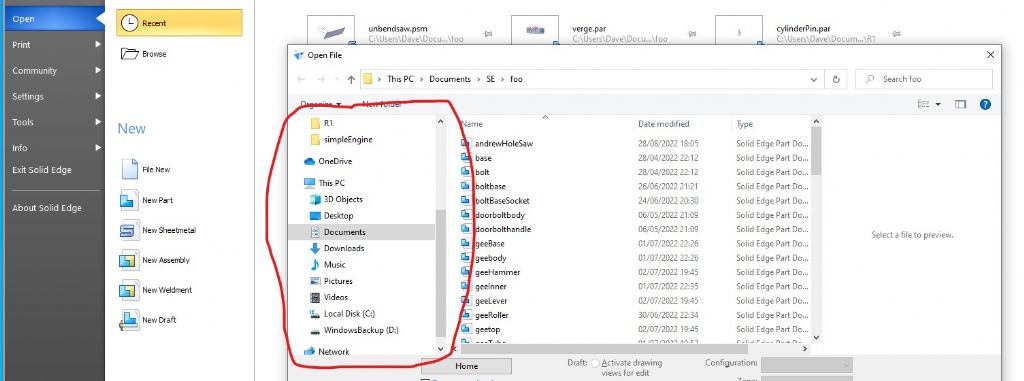

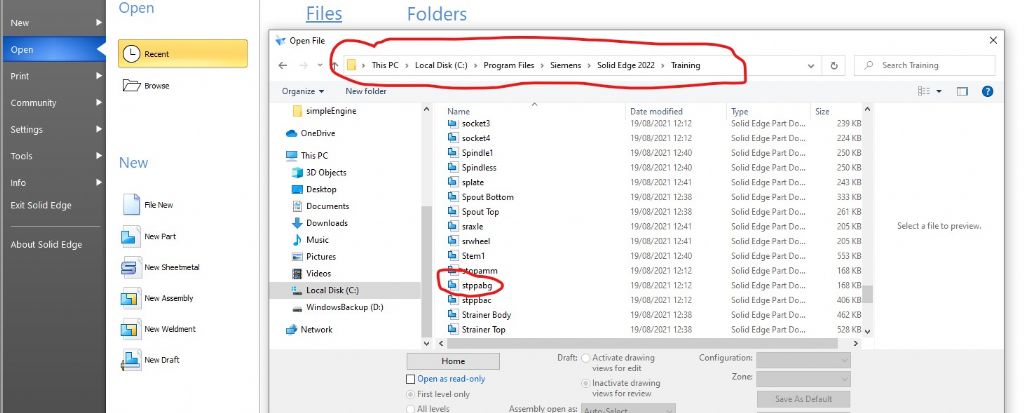

This is where I hit the end-stop; with Siemens' phrase "Look in" which seemed a tool-name, but which you tell me is really called the "Navigation Pane". So why didn't it use the proper name and path?

I have just tried searching, using the clues you give above. It lets me browse my PC, but the only SE drawings in there are my own attempts. This revealed that I had stumbled across yet another tutorial, drawing a rectangular Z-shaped bracket. I have no idea where that came from!

'

CAD is extremely difficult to learn anyway, but SE seems made as difficult and confusing as possible.

I must have spent hundreds of hours – and umpteen kW/h electricity – trying to learn CAD.

I progressed just enough with TurboCAD first, to make very rough orthographic drawings. Its 3D "model" mode is impossible; as is its very strange paper-printing system. It cost ££ too, this did.

Now with Solid Edge (Community Edition): 3D-first but appearing to be easier, slightly better documented and having none of TC's horrendous traps. Though a quick look at its "Print" tool suggested that is little better than TC's "Viewport" nightmare.

It's not much help "nailing" the basics, though, if they won't let you.

.

I knew before I started what CAD can offer expert users – the drawing-office at work used SolidWorks – and though I realised it would not be easy to learn, I thought it might genuinely help my model-engineering.

Right on the first point; half right on the second (not just "not easy" ; virtually impossible). Completely wrong on the third.

The two magazine are now full of pretty-coloured images of machinery, their workshop drawings to full CAD quality, photos of 3D-printed things, and articles on CNC machining. All beyond me, but I was not aiming for those lofty heights. I wanted only to draw efficiently, things I want to design, to help me make them.

Nigel Graham 2.