Don't get hung up on Ordered versus Synchronous. With few exceptions it's more convenient to work synchronous mode, with Ordered in reserve if necessary. So ignore Ordered for time being.

Here's an example to show the difference. The example is a cube with a hole in it, where I decide later to move the hole and alter its diameter.

FreeCAD and most other 3D-CAD packages are Ordered.

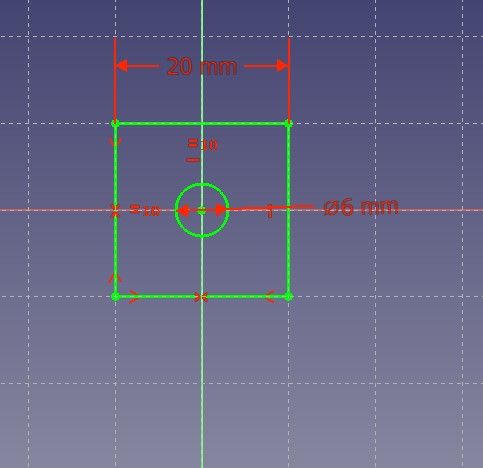

Step one is to 2D Sketch and dimension a square with a circle representing the hole.

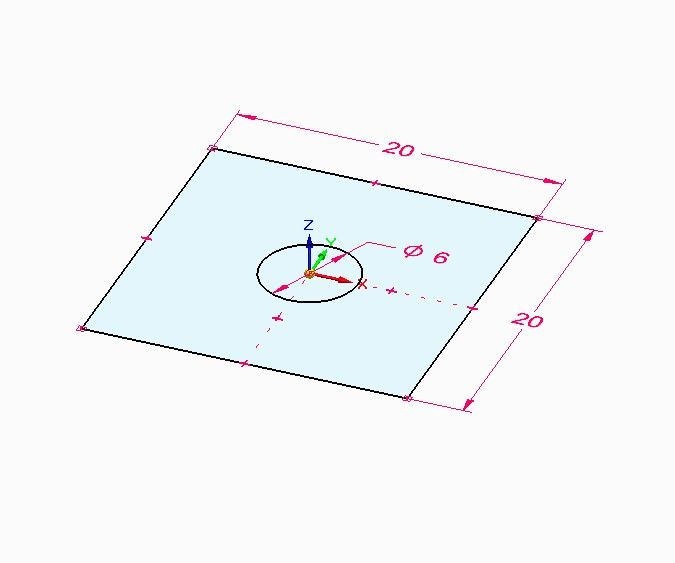

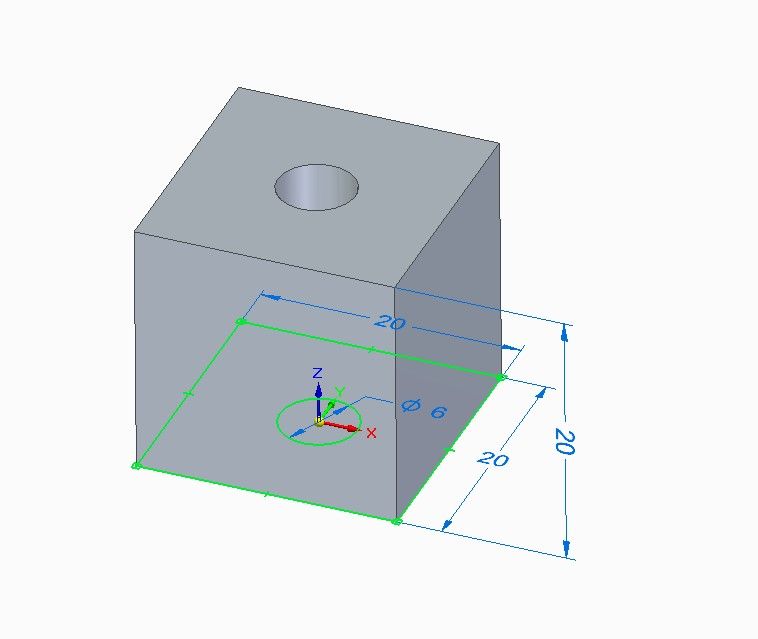

The sketch is then extrude by 20mm to create the holed cube:

I realise the hole is too small and should be off-centre. In Ordered (aka History), this is done by editing the original sketch:

The extrude is automatically re-applied when the sketch is saved:

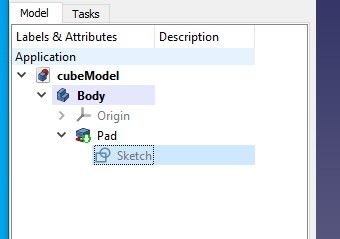

So in Ordered Mode, models are a stack of sketches each building on previous work. All the sketches are retained within the time-line and can be edited to alter the model, in my example by moving the hole. Below the cubeModel model consists, in order, of a Body, which has an origin, containing a Pad (Extrude), which depends on a Sketch

Solid Edge has a Synchronous Mode as well. In synchronous mode, sketches are used to start the model, but thereafter the model is modified directly, and the sketches become redundant.

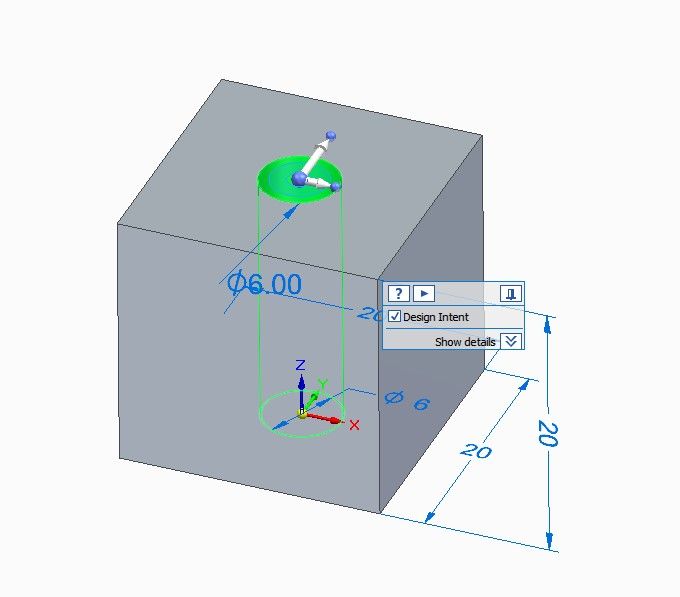

Step one is identical to Ordered Mode. A sketch is drawn and dimensioned:

And the sketch is extruded in exactly the same way:

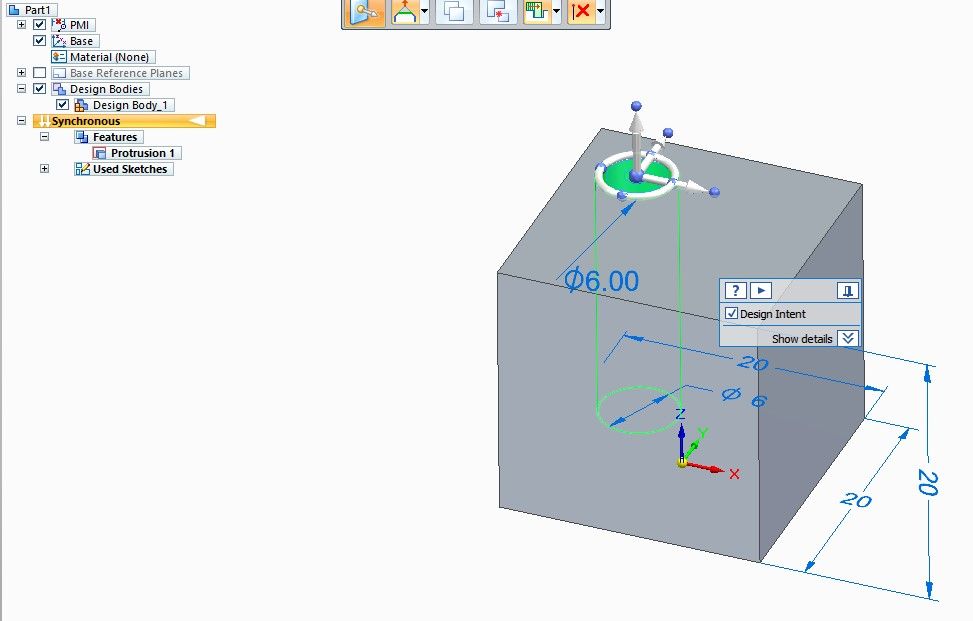

The difference between ordered and synchronous appears when a synchronous cube is changed. The hole is changed directly on the model, not by editing the sketch. Pointing and clicking on the hole activates a wheel tool that can reposition the hole:

The hole can be dragged and rotated, here dragged:

Note that in synchronous mode, the part breakdown (list left) is a Protrusion (the holed cube) that doesn't depend on a sketch, and there's a container of Used Sketches. Changing the model in 3D invalidated the 2D sketch, so SE archived it. It soon becomes impossible in Synchronous mode to change the model by altering sketches. Synchronous models don't have a sketch history, so the model is changed by moving forward rather than going back to an earlier state.

In practice changing the model directly rather than editing sketches works well, but there are times when Ordered mode does a better job. Solid Edge models can be Ordered, Synchronous or a mix of both. Everything I've needed to do so far has been achieved comfortably in Synchronous mode – it works.

In short, ordered mode depends on 2D sketches, which remain important throughout, whilst synchronous mode only uses 2D sketches to start the ball rolling and then drops them.

Dave

Edited By SillyOldDuffer on 24/08/2022 16:47:48

Nealeb.