SE (CE) – Any Manuals Available, Please?

SE (CE) – Any Manuals Available, Please?

Home › Forums › CAD – Technical drawing & design › SE (CE) – Any Manuals Available, Please?

- This topic has 61 replies, 11 voices, and was last updated 24 August 2022 at 22:21 by

Nealeb.

-

AuthorPosts

-

21 August 2022 at 23:28 #610657

Nigel Graham 2

Participant@nigelgraham2Tried again this evening.

I found the "introductory" stuff on the Siemens web-site, supposedly aimed at CAD beginners – thinking if I want to learn a new make of CAD I should start as far back as possible.

It throws you right in the deep end. Typical IT people – they think you either as bright and knowledgable about advanced computing as they are, or useless.

A woman with a strong American accent (this company is German?) waffles over a fast-moving advertising video. After highly disingenuous picture of a drawing-board with loose T-square and set-square, she launches into what Solid Edge can do; using a mechanically-simple roller assembly as example.

Within the first minute or so of about 9, I was lost. All quick-fire images, cursor-clicking and undefined jargon like "synchronous" and "ordered" things called "environments". Whatever they are, which is the right one to use and if one is wrong, why have two?

She says "we will now draw…. " Who's this "we" , then, oh Los Angeles lassie? We learn she can draw the assembly in 3D, then one of its journals in 3D and as orthographic elevations with inset isometric image; even a parts-list. Clever her. Or a good commentator.

(I knew long ago that the 4-view facility exists – from drawings at work and in the Hemingway Kits.)

'

Badly demoralised, I tried Siemens' next step in making me feel stupid. I think this, an introduction to making a simple rectangular plate as baffling as possible, starts that stylised micrometer you mention.

Without two computers – one for the instructions, the other the CAD programme itself – I could only try to remember enough to attempt it. Opening the drawing application seemed to close the rest of it.

Somehow I drew a plate to dimensions I set myself. Then another one near it.

Then… that was it. I had not really grasped anything, could go no further.

Finally, I could not close the programme from itself, and had to use Task Manager – this revealed the introductory site still open, which I had not expected.

I'd hoped SE might be a simpler programme to learn than TurboCAD but I now doubt it. At least TC has none of this "synchronised environments" rigmarole.

22 August 2022 at 03:32 #610659 PatJParticipant@patj87806

PatJParticipant@patj87806I found an automated-voice valley girl tutorial for SE.

This must be the one Nigel is referring to; and I agree, totally annoying voice by any measure.

The problem I found when trying to learn 3D modeling is that the tutorials are not very focused, and they are often an advertisement for features.

I found Solidworks to be terribly intimidating, until I found out that I basically only use about 10 commands over and over again, and perhaps 90% of Solidworks I will never need or use.

I found the Solidworks tutorials incredibly frustrating, and there were no tutorials on how to best 3D model an engine such as we build.

I swore off learning 3D modeling over and over again for about a year, and finally got enough traction where I could start learning to make primitive 3D models.

I could sit behind someone and teach them 3D modeling in about a week I think, a few hours per day.

I had to teach myself; I did not know any tutors.

I highly advise you to ignore synchronous mode, and stay in the standard mode (I forget what SE calles non-synchronous mode).

Once you master standard mode, then consider learning synchronous mode.

If you get in a pinch with standard mode, then I or many others, regardless of what software they use, can probably help you.

If you start using synchronous mode, you will lose a lot of help from folks who don't use that.

For me, learning 3D modeling was like carving a statue out of granite.

You chip off a few pieces every night, and make little progress for a long time.

Suddenly a shape begins to appear, and you start to figure out what it is you are suppose to be doing.

Once you figure out the basic 10 commands that you generally use, then you wonder "why did they make it seem so difficult in the tutorial?".

The answer is they are trying to sell features, and the more features they announce, the more money they can charge you. It is a features-race between the other software companies, but as I mentioned, 90% of the features you will never need or use.

When creating my 2D sketches, I use typical 2D drawing tools, such as line, trim, offset, circle, etc. (basic shapes). I start by opening a new PART file.

When I get my sketch done, I toggle over to 3D mode, and use a 3D command to do something with the sketch, such as extrude, cut, revolve, etc. and I make some sort of 3D solid shape from that 2D sketch.

Rinse, repeat, rinse, repeat.

Its the same thing over and over.

Go to 2D mode, make a sketch, toggle to 3D mode, extrude or cut with that sketch.

That is almost all there is to it.

Making 2D drawings in Solidworks involves opeing a DRAWING file, and dragging and dropping a 3D shape onto the sheet, where it creates a 2D front view, and then dragging that view up, down, sideways, and diagonal to create a left view, right view, top and bottom views, and isometric views.

Save your 2D sheet and print it.

I create one PART file at a time, for each piece of an engine.

Once each part files is done, I create an ASSEMBLY file, and drag and drop each part into the assembly, one at a time, and then mate then in the correct orientation.

My brother saw a screen shot of my Solidworks, and he said "Boy, that sure does look complicated", and I said "If you knew how few commands I actually commonly use, you would not say that".

It looks a lot more complicated than it really is.

I can definitely relate to your frustration though.

Been there, done that, banged my head on the wall for a long time; but I learned it in the end.

.

Edited By PatJ on 22/08/2022 03:36:13

22 August 2022 at 07:08 #610662 JasonBModerator@jasonb

JasonBModerator@jasonbWell it can't be too bad a video, within the first 60 seconds it shows you where to go to print a paper drawing, something that you had not found in 6months or more.

It's really just a quick overview rather than a how to video.

Better to go to their channel, look down the playlists and find the one "Learning Solid Edge"

Then try a few likely videos possible like getting started if you are new to CAD or Transitioniong to SE from other CAD

Edited By JasonB on 22/08/2022 07:10:39

22 August 2022 at 08:14 #610665 JasonBModerator@jasonb

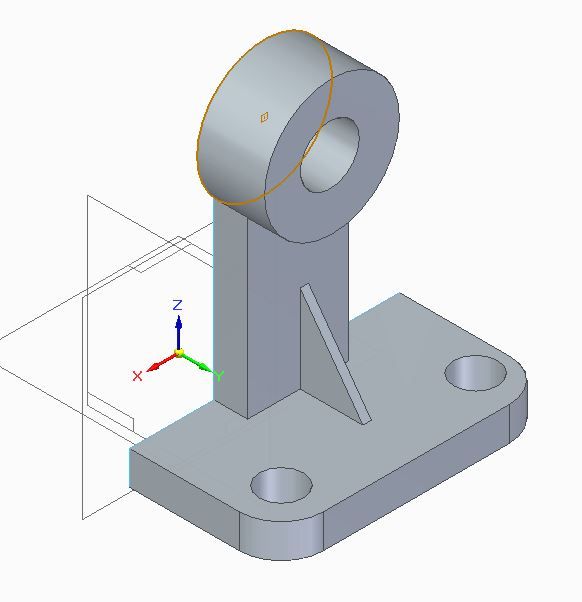

JasonBModerator@jasonbWell I managed the part in the first video above, probably jumps about a bit quickly but Nigel may find it better to set the Youtube playback speed a bit slower.

Don't have a problem with the voice and a better option than had the German company had a German voiceover. No problem flicking back and forth between the video and SE but that is just basic understanding of windows and what programmes you have open on the taskbar.

22 August 2022 at 08:30 #610667lee webster

Participant@leewebster72680I think this voice is a computer reading a text file. Annoying, but it gets the job done. When I tried to learn Solid Edge I found the youtube videos by a doctor or maybe professor Seif very good.

John, Virtually all modern computers enable you to have more than one window open at once. You could have a Solidedge tutorial open in youtube, pause it and switch to Solidedge running in another window to draw what you have just watched, and then switch back to the tutorial. There is normally a bar acroos the bottom of the screen, on windows it is called the task bar, this bar shows you what programmes are running.

I must admit that Solidedge had too many features I didn't need to make it of any use to me. But oddly, SolidWorks didn't seem to make me feel the same. Perhaps it's because I was using the student version which is a cut down version of the full programme. I would rather use SolidWorks, it's just too expensive.

22 August 2022 at 09:44 #610672IanT

Participant@iantHi Lee,

It's Dr Mohamed Seif and he's Professor of Mechanical and Civil Engineering at Alabama A&M University

His early videos were just intended for use by his students I believe but he seems very happy that others find his videos useful and he updates and changes them over time. He now calls his YouTube channel "The Design Engineer"

Introduction to Solid Edge – The Design Engineer

I've always found his expanations very easy to understand, he doesn't rush through things, explains what he's doing and even makes the odd mistake (which he corrects – which is also useful). Highly recommended.

In terms of the number of features available, you can of course select different interface levels but I chose to just go straight for 'Balanced' (the defacto UI) and learn that – there are simpler UIs though. It may look complicated but it soon becomes quite normal.

I very much like the 'find a command' feature (At bottom of screen) as my memory isn't what is was. It will show you a list of suggested commands it thinks you are looking for and highlights the required icon as you hover over it in the list. The associated "?" will link you to the help file for that command (a very useful reminder for less frequently used commands).

Regards,

IanT

22 August 2022 at 10:08 #610674Nigel Graham 2

Participant@nigelgraham2Thank you.

On the supposed introductory video, showing what SolidEdge can do, obviously I expected the English-language web-site to speak English, but not Siemens going all the way to America when there must be plenty of fluent English commentators in Germany, and Britain is very close geographically!

My main beef though is that this cheapskate advertisement lasts nine minutes, and makes the software seem even more baffling than it might be.

'

Don't use "synchronous mode", or "synchronous modeling" [sic] as it calls it, whose opposite adjective is "ordered" ?

Siemens assume we all know what their terms mean even before you start, as a complete CAD novice! The first instructions on using the programme tell you to use synchronous setting – but why? What is it?

.

I had wondered if "Synchronous" is connected to file saving and exchanging. CAD at this scale is primarily for high-level industrial use that might spread projects over thousands of individual files shared around many projects and computers, sometimes internationally. It seemed logical to have a system in which a change in an original part drawing can be transmitted automatically to the related parts drawings, and to all their copies in the network.

Wrong. No logic.

I learnt Synchronous and Ordered are different drawing modes or methods when I tried using the software; but not their meanings, purposes and choice.

Once I had gone as far as I could, I experimented a bit. Switching to "Ordered" changed the tool-bar, and was not obviously reversible.

Also, whatever I had done to cause it, I needed use Task Manager to close SE.

'

Now, the web-site's operating instructions complicate the subject, but are at least static, not videos. So I am grateful for that, as I cannot learn from videos anyway.

Videos like that preface would teach no-one anything. I largely abandoned YouTube after Google started continually interrupting its videos with childish, pointless advertisements.

.

I had also found information about my licenced copy, and it suggests Siemens itself questions why bother at all.

It expires in 30 months time, probably 3 years from installation. For me, perhaps long enough to learn to draw a 4-way tool-post block, at a stretch the complete QCTP Ian suggested; maybe some parts but not the entire compound engine for a miniature steam-lorry; but then what?

Full industrial cost (£x000), for any further use?

For Siemens appears to intend 'Community Edition' for students; and three years is the usual length of a degree course. The software is of corresponding difficulty, meant to be taught within either a university engineering or architecture course, or the trade as a new system to professional draughts-people already experienced in CAD. That Siemens lets we amateurs use it for free for three years is generous, but possible only because very few of us could afford to use it at all otherwise, and the offer does not hurt the company financially. If it wanted to be tough it would limit the licencing to sales-only: i.e. to wealthy academic and industrial institutions.

Of equivalent, near-industrial standard CAD makes, Alibre became sales-only once its "free" MEW promotion ended; and Fusion seems to keep its users guessing. You have to buy TurboCAD, but by honest, single, up-front purchase; and its near-equivalent to SE(CE) is not desperately expensive. I don't know the situation with AutoCAD, but I think it is trade-sales only so would be hellishly expensive.

22 August 2022 at 10:22 #610678 JasonBModerator@jasonbPosted by Nigel Graham 2 on 22/08/2022 10:08:49:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 22/08/2022 10:08:49:Videos like that preface would teach no-one anything. I largely abandoned YouTube after Google started continually interrupting its videos with childish, pointless advertisements.

Depends on the individual I suppose. I watched it and produced the example part so it taught ME how to use the various commands SE.

I think the Block that has been mentioned by others is not just with SE but with computers in general, and not being able to move on from paper documentation. Until that block is lifted I don't see you progressing and you will just be at the same level you have been for the last few years as all the posts about CAD have not changed in that time.

I expect their largest English speaking market is the US and Canada so seems reasonable to pick a voice that suits

22 August 2022 at 10:55 #610681Ex contributor

Participant@mgnbuk" obviously I expected the English-language web-site to speak English, but not Siemens going all the way to America when there must be plenty of fluent English commentators in Germany, and Britain is very close geographically! "

Solid Edge was originally developed in the US – Siemens bought out the original developer. From Wikipedia :

Originally developed and released by Intergraph in 1996 using the ACIS geometric modeling kernel, it changed to using the Parasolid kernel when it was purchased and further developed by UGS Corp in 1998. In 2007, UGS was acquired by the Automation & Drives Division of Siemens AG. UGS company was renamed Siemens Digital Industries Software on October 1, 2007.

So not so strange that the content is American – most likely the product is still based / developed there.

Nigel B.

22 August 2022 at 11:22 #610686Nigel Graham 2

Participant@nigelgraham2Hmmm. I have not yet found a video that can actually help me learn anything! I have learnt from videos what others have done, but that's not the same thing.

My "block" with CAD is not a "block" with computers generally, as you think; but you are probably right I will never learn to use CAD, at least not to a very useful level.

I did not touch a computer until c.1990 when a change of work brought me face-to-face with them. One of my first training-courses there was an Introduction to MS-DOS! Followed by others over the next few years on MS 'Windows, 'Word' and 'Excel.

The last was very much part of my work, for collating test result while swearing at Mr. Gates for not knowing 360º = 0º, nor giving decent axis-annotating routines, on polar graphs he called 'Radar Charts'. (We typically used 3º increments, and 'Excel' seemed to think we wanted every angle value labelled.) I still occasionally use Excel, mainly for model-engineering calculations.

I had also picked up a modicum of BASIC thanks to local programmes on laboratory computers driving electronic analysers; and developed this a bit further on my first own computer, the Amstrad PCW9512 on which I also wrote the mss for a cavers' guide-book. (Though primarily a word-processor, with its own printer too, the Amstrad came with compilers for BASIC and very strange language called DR LOGO – which did fox me.)

.

So my block is not of computers per se but of specific applications; but part of a much broader aspect, that of my natural limits to learning anything.

My models, if I ever finish them, will never be of Model-Engineering Exhibition quality – I'd be lucky to pick up "Commended". There are huge expanses of the subterranean world I would love to have visited with my caving friends, but too difficult for me even when I was younger and fitter. Early dreams of a science or engineering profession were impossible because I cannot learn mathematics beyond a very low level; although my entire working life was at shop and lab floor level in these fields. I do not have the memory for foreign languages. When I gained an A-level in Geology in evening-classes some years ago, fellow geology-society member brightly asked me about taking an OU Degree in the subject, but that would have been beyond me.

'

I have a theory others more qualified than I refute but not convincingly, that aptitude is not only highly individual but rather like a bucket. Think of a row of buckets on a beach; each its own size, labelled with a practical, academic, sports, artistic, etc. subject. Start filling each bucket with water: once it is full any extra water just overflows into the sand. You cannot extend the bucket, so it will never hold more than its original volume.

If this were not so, why is every Sunday League footballer not being head-hunted by Manchester United; every pub-pianist not performing Rachmaninov or Beethoven at the Proms; everyone who knows the difference between power and energy not progressing to designing power-stations or managing CERN… and so on?

'

If I stall with learning TurboCAD beyond what I have managed so far; or SolidEdge at all, it is not because they are CAD systems or even just on computers, at all.

It is because I have reached my physical capacity with those particular skills!

'

[Don't tell me Jason… you are one of the world's best research neurophsyiologists and psychologists with a particular speciality in the mechanics of memory and comprehension, so…

)22 August 2022 at 11:32 #610690

)22 August 2022 at 11:32 #610690SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 19/08/2022 21:49:51:I know, Ian! I was trying to refute the "mental block" charge.

It's a diagnosis, not a charge, and one based on direct personal experience.

Having done technical drawing at school I found 2D-CAD at work quite difficult (Autosketch). Later, I attempted to learn AutoCAD and made slow progress mainly because it did things differently to what I already knew. I was saved by a promotion that didn't require me to draw anything.

At home, I settled on QCAD (2D), which eased me in because it's rather like Autosketch and I didn't have to unlearn much. FreeCAD (3D) proved very difficult at first because it introduces another way of doing things as well as a complicated set of complicated commands. I found unlearning harder than learning. For example I kept looking for QCAD-type advanced 2D features in FreeCAD's Sketch Editor. They aren't there, and feeling the need for them was a strong clue I hadn't twigged what Sketches are and how they work.

Later, because it does Assemblies, I learned Fusion360. Although Fusion commands differ in detail from FreeCAD, learning was accelerated because the way models are built in Fusion is similar to FreeCAD. I didn't have to unlearn a fundamental idea, as I had when going from QCAD to FreeCAD.

Although I give Fusion top-marks for ease of use and power, I don't like storing stuff in the cloud or the way AutoDesk altered the licence conditions. Ian recommended Solid Edge, so I tried it. The non-commercial version is pretty much full-function and it's not a cloud product. The licence conditions are still a risk – product runs for about 900 days – but I don't think Siemens can alter them on the fly as is possible with Fusion. (I don't blame vendors for having licence conditions: they're in business to earn a living, not to give freebies to miserly Model Engineers!)

Solid Edge landed me with a major unlearning problem. Not only are its complicated commands different in detail and organisation, but the product takes a different approach to modelling. Although I'm making good progress, it's not been easy. An interesting side-effect is I can no longer drive FreeCAD and Fusion as well as before because I subconsciously expect them to behave like SE, and they don't! More unlearning.

The cure is not taking anything for granted. It's essential to start with the basics and persist until simple single-part models behave as expected. I make progress by creating very simple objects and gradually moving on to more challenging constructions. On the plus side, Pat said he does almost everything with 10 commands. Fewer are needed to get going, but they have to be mastered, not skipped over.

The way CAD software behaves when poked by incompetent learners is an obstacle too. Because programs don't know what the operator is trying to achieve, it's possible to create models with internal flaws. Eventually the program can't cope with the mess, and misbehaves. Crashes, commands misbehaving, the model taking unwanted shapes, or jambing. Crashing is probably the least confusing outcome, because the other malfunctions take the Learner into a netherworld where nothing behaves properly. Don't be afraid to restart the program, or start models from scratch, because this often cleans out the invisible debris left by mistakes.

Books and internet tutorials don't make learning easy either. Quite often they're badly out-of-date. Some web tutorials are excellent whilst others mislead, but the hard part is finding one that covers what's needed.

It's the Learners job to get his head around how the computer works, and unfortunately in this case it's essential to ignore previous experience. Counter-intuitive because almost all other learning is built on previous experience, and difficult to ignore because what we know is deeply embedded. It's hard! As far as I know, no-one teaches unlearning.

Dave

22 August 2022 at 12:51 #610700Nigel Graham 2

Participant@nigelgraham2Flicking between tutorial and drawing –

I am of course familiar with having two or windows open and stacked, but I thought opening the drawing itself had switched off the tutorial one.

.

Prior Knowledge –

I will admit it was hard to try not to think TurboCAD with my first attempts at SolidEdge. I do though try to start right from the beginning – just as with having bought a new power-tool or some home-assembly item, I actually read the instructions first!

I started relatively well, with IanT's help, but then hit a wall partly because the tutorial stuff on Siemens' own site throws a lot of its own jargon – not just generic terms – at you without explanation. What is explained seems to make the thing look harder than it might be.

I expect there are traps in any make of CAD, and most serious software generally. Try finding an arcane error in a multi-step mathematical formula translated into 'Excelese' – its syntax is quite involved and though it does help you correct that, you need know how it is helping you.

It seems one of the main traps for beginners in TurboCAD is switching between 2D and 3D in mid-drawing – you have to set one throughout and it is horribly easy to make the switch by mistake, let alone deliberately. It also loves hiding line trimmings beneath the visible ones, causing all sorts of failures until you twig that careful cursor-ing highlights the off-cuts for deleting without undue curs-ing.

SE seems to rely on dimension-mode switching; but I do not know about hidden fragments. I have not used it enough to find its devious tricks and pitfalls…..

I can quite believe Pat finding he needs only about 10 commands, at least for his projects. Perhaps careful planning of the drawing, not just the design, helps there. The difficult bit is knowing which 10 out of what, 100? , to use, and how to find and use them at what point.

'

Licence –

I do not suggest Siemens will alter its licence conditions "on the fly" . Obviously it has the right to change them, but I think would do so in an honest way – it has its reputation to consider. I had not though known that the CE licence is only for three years (it had said something like "280 days left" : about 30 months), and it does not say what happens after that – simple renewal or purchase.

In the grand scheme of things, the relatively few amateur users willing to buy it may cost Siemens more in administration than they are worth – the engineering graduates would have had the full cost paid and when (if) they find employment using SolidEdge / Works, their employer is paying the full charges. (My employer used SolidWorks, I think.)

'

Fusion 360 files –

The so-called "Cloud " – more jargon, why not just be honest and say "Internet" – is Fusion's default, but not compulsory. At least, it was not when I tried it, briefly, a few years ago. The choice is or was there but not stated too obviously.

I imagine a lot of commercial Fusion users would block that default, for security! Or simply refuse to use any software that behaved in that way.

22 August 2022 at 14:37 #610718lee webster

Participant@leewebster72680When I had Solidedge installed on my CAD computer the system date was not "up to date" as it were because of another CAD programme I was using, Designspark, that wanted to log on to its home site each month. My CAD computer isn't connected to the internet and I didn't want Designspark to get upset, so I keep the system date at the same date I installed Designspark. Maybe by doing that I was confusing Solidedge into thinking it hadn't been installed long enough to tell me to upgrade. Designspark does give a message each time I run it that there is no internet connection. Solidedge never did. I wish I had tried the date thing with SolidWorks, I might still be using it!

22 August 2022 at 15:25 #610728SillyOldDuffer

Moderator@sillyolddufferPosted by lee webster on 22/08/2022 14:37:47:When I had Solidedge installed on my CAD computer the system date was not "up to date" as it were because of another CAD programme I was using, Designspark, that wanted to log on to its home site each month. My CAD computer isn't connected to the internet and I didn't want Designspark to get upset, so I keep the system date at the same date I installed Designspark. Maybe by doing that I was confusing Solidedge into thinking it hadn't been installed long enough to tell me to upgrade. Designspark does give a message each time I run it that there is no internet connection. Solidedge never did. I wish I had tried the date thing with SolidWorks, I might still be using it!

Fiendishly clever but messing with system date-time isn't recommended because so many things rely on it. Backups, Security Certificates, Networking, Timers, and dozens of scheduled tasks are all liable to get confused if the system clock jumps backwards. Approach with caution – only if the machine is truly stand-alone and single-purpose and backup/restores are done manually. I certainly wouldn't risk it on a general purpose computer full of important data that was attached to a network!

Dave

22 August 2022 at 16:36 #610736SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 22/08/2022 12:51:51:.

…

Fusion 360 files –

The so-called "Cloud " – more jargon, why not just be honest and say "Internet" – is Fusion's default, but not compulsory. …

Ah, ha! I suspect the comment above is the mental-block caught in action! I suspect at least 15 years ago Nigel did a course where the internet was pictured as a cloud symbol – me too. But technology has moved on considerably; Cloud means more.

May seem pedantic but the internet isn't the cloud. The internet just an enabler, and the alleged jargon is a clue something is different. Cloud now means some sort of sophisticated on-demand service, were a significant part of the action doesn't take place on the users computer. Examples include:

- Platform As a Service (PaaS) – providing access to an entire operating system, usually set up as a server, where the vendor manages security, backups, availability and performance, while the user provides software and data.

- Software As a Service (SaaS) – as above, except the user only provides the data and configuration. The application, perhaps a big online shopping operation, is part of the service.

- Infrastructure as a Service (IaaS). Complex combinations of SaaS and PaaS managed as a unit, usually to deliver high-performance and high-availability. Adds features such as load balancing. This is for customers with major needs: Disney and such. Customers typically don't want the responsibility of owning and managing a big IT operation, and would rather concentrate on core business (entertainment), rather than worry about the data centre roof leaking, running out of space, employing security guards, and other computer related hard work. All that is in the 'Cloud', included in the price, and the Cloud provider is responsible for all the details.

The problem is privacy and loss of control. If the Cloud manager cocks up, all a customers data could be lost, mangled or made public. Whatever glossy promises were made the business risk of a cloud failure is fully held by the customer. For that reason many organisations prefer to keep their IT in-house. Particularly likely when an organisation uses IT to maintain market advantage or needs to be sure competitors won't find out what they're up to.

Fusion is a Cloud product. Although it operates off-line for a while, the facility is meant to cover temporary network outages, not to provide a stand-alone CAD system. Storage is primarily in the cloud and Fusion regularly has to connect to resynchronise data and check the licence is still valid. Not sure what the latest state of play is, but last time I checked a user could only stay offline for about a month. After that, the product won't start unless it connects to base first. On connection, it re-syncs data and download updates. The updates can include licence condition changes, as well as new goodies. Autodesk's decision to restrict the hobby version to a maximum of 10 open files landed on the community out of the blue.

Dave

22 August 2022 at 17:04 #610741lee webster

Participant@leewebster72680Dave.

My CAD computer is only used for CAD and the slicing software for 3D prints. So it is as stand alone as I can make it. It is only a small laptop with a solid state drive, but with no anti-virus and internet shenanigans to slow it down, it is fast. Boot-up, 10 seconds. Solidedge, 5 seconds. Designspark, 8 seconds. On my old plodding internet computer Designspark takes over 60 seconds to load, Solidedge would take 2 to 3 minutes. I could do with better graphics on it, it only has the built in graphics which aren't up to much.

22 August 2022 at 17:40 #610744Nigel Graham 2

Participant@nigelgraham2Dave –

Thank you the explanation but I am afraid your assumption is wrong. (You're not the first in that respect.)

I had never heard of the 'Cloud' in Internet terms until I looked at Fusion 360, which waffles excitedly about it. I had to ask someone else what it meant; and gained as the only explanation, remote WWW servers.

The IT manager at work laughed at the very idea of our company even considering such external storage.

.

Out of curiosity, how might a maximum of 10 files open affect CAD in model-engineering terms? I can envisage maybe a general-arrangement and perhaps two or three sub-assembly drawings open when working on some additional detail part or a modification to to one of the latter; but that's only four or five files, isn't it? Could you bypass the problem by copying the relevant material to the field around the GA, temporarily, so you have their separate existences but reduce the load to just two open files?

(Some of my drawings are like my workshop – and home: an untidy sprawl of sub-assemblies, parts and odd constructions around the main subject. It would probably offend the TurboCAD Users' Forum experts, but that and the "unofficial" ways I need use to copy an assembly or part to a new drawing, or to a paper print, are the ways I know!

)22 August 2022 at 18:55 #610768

)22 August 2022 at 18:55 #610768Nick Wheeler

Participant@nickwheelerThe 10 files isn't a huge problem if you manage them properly. And you can reassign at any time which of your files are the 10 you can edit. Completed jobs can still be viewed even if they're not one of the 10.

The chassis I showed earlier is just one file, with each of the parts within it a separate component. Not doing this would be like storing the manuscript for a book as a separate file for each paragraph.

Cloud or local storage for my own stuff is unimportant. That would change for business use, as some form of local and secured storage would be necessary.

So far, I haven't needed to stump up the cash for a Fusion subscription, but will do so if it becomes useful. I think it's a terrible way to buy anything, and would much prefer a one-off, own it forever deal. And any software that is free to download and is likely to end up costing you at some point.

Edited By Nicholas Wheeler 1 on 22/08/2022 18:56:03

22 August 2022 at 19:30 #610778Nigel Graham 2

Participant@nigelgraham2I am not sure I would trust a subscription to any software, suspecting it could be horribly easy to become too expensive, and horribly difficult to end.

I see your point about the files. Storing book paragraphs as their own files would be indeed by silly and wrong, but individual chapter files, appropriate. (A book I co-authored, but typed all myself, was made like that.) Similarly with CAD but depending on the nature of the project, especially if it holds many parts common to other projects.

It would not worry me unduly using the 'Cloud' for storing my drawings. It was more the principle of the thing I objected to, rather than the amusing idea of some rogue state's security services trying to decipher my attempts at a Compound Steam Engine's cylinders. The more serious point might be their existence for criminal hackers trying "jigsaw indentifying" .

22 August 2022 at 19:58 #610788SillyOldDuffer

Moderator@sillyolddufferPosted by Nicholas Wheeler 1 on 22/08/2022 18:55:32:The 10 files isn't a huge problem if you manage them properly. …

Agreed, but you do have to manage them. I'd rather get on with design than worry about opening and closing files to stay within a limit. It happened the project I was doing when the limit dropped was an assembly with 12 open parts, so I felt immediate pain.

Although it's possible in Fusion to put more than one part in a file it goes against the grain. The objection might just me having trouble unlearning rather than logical…

Don't get me wrong I like Fusion very much. It's just SE fits my needs better. Just like Nigel's IT Manager friend, I'm not keen on the cloud. Might be because the Cloud makes IT Managers redundant!

Dave

22 August 2022 at 21:42 #610813Nigel Graham 2

Participant@nigelgraham2Redundancy up in the cumulus was not my fellow-employee's worry!

The company could not put anything on t'Net for protection, but even if it had, the IT department would still have been very busy.

.

I have just paused to have a look at the down-loaded SE manual.

The first page is a bit daunting but the step-by-step instructions and their diagrams are very clear; making me feel a bit happier about it!

'

A curious optical effect:

I don't know if it's because I am used to having the grid on all the time in TurboCAD (it is optional) but starting a drawing apparently floating in space feels slightly unintuitive and uncomfortable.

Yet a manual drawing on plain paper also starts in a white "space". What's the difference? There, I would start with a base-line or the centre-lines to belay the thing to something apparently tangible (like the grid on the screen). Further though, although flat with no depth even in isometric projection, the "thing" is lying on a very tangible hard surface I can feel through the pencil. In CAD, when you order a line 100mm long, you are not making the line. You are telling an intermediary, the computer, to make it.

It's probably the illusion of limitless depth, the isometric angles and the non-tactile nature of screen-based image-making that create this disjointed feeling.

I do not notice it with photographs though, such as in the advertisements to the side of this, even of the Eccentric Engineering tools shown without backgrounds.

22 August 2022 at 23:17 #610830SillyOldDuffer

Moderator@sillyolddufferI like grids when starting sketches off, but they soon get in the way when the sketch is drawn on a face rather than a plane. Drawing in 2D, one is always in one plane (XY), and the drawing is manipulated to create projections which, by convention, represent planes.

In 3D-CAD, sketches can start in any or all of the planes XY, XZ or YZ and the 3D objects they represent are created by extruding XY in Z, XZ in Y, and YZ in X. In addition, sketches can be drawn on faces that aren't normal to any of the 3 ordinary planes, so 3D-CAD supports an infinite number of planes all at the same time. SE has a 3D sketch tool that allows lines to be drawn in all 3 dimensions at once, not on a plane or face at all. (Other 3D-CAD have similar tools.) In 3D grids can be confusing! I agree at first their absence and lack of pencil feedback creates a disjointed feeling.

Dave

23 August 2022 at 04:35 #610838 PatJParticipant@patj87806

PatJParticipant@patj87806I learned how to extrude basic shapes in 3D modeling, but then I got stuck trying ot figure out how to extrude something that was not on the standard front, top, side planes.

It took me a while to figure out how to insert a plane in the correct place, and then how to rotate it to where I needed it.

That was a quantum leap in ability once I figured out the plane thing.

.

23 August 2022 at 09:28 #610850IanT

Participant@iant" I have just paused to have a look at the down-loaded SE manual.

The first page is a bit daunting but the step-by-step instructions and their diagrams are very clear; making me feel a bit happier about it! "

Congratulations Nigel,

Your Solid Edge Manual 'Quest' seems to have finally succeded!

Keep on questing and I'm sure you will have further sucesses!

Regards,

IanT

23 August 2022 at 23:29 #610978Nigel Graham 2

Participant@nigelgraham2Thank you!

Yes, found it! Not ever so easy to find because the web-site was rather blinding me with science.

'

I spent a while today making a printed version of the manual's Contents list to use alongside the full document on the screen.

I could probably have just printed the pages directly, but instead compressed a copy by 'Word' and 'Excel' to a two-page spreadsheet document, without all those long lines of dots.

I had done similarly with TurboCAD but going much further, creating a true alphabetical index, using the MoD-style 'noun-adjective-adjective' convention. SE's Contents page is a lot simpler and more obvious to follow; and in my copy I highlighted the "chapter" headings to aid searching.

'

Then tried the initial exercise, sketching a T-shaped two-dimensional plate with a hole in it. It suggests not saving it afterwards but I did, having added a second hole for luck; so I can play around with it further if I want.

As I did but not saving the changes; rather vaguely extruding it and trying to dimension that – with odd results. I had found the dimensions are active and associative but also that unless you handle them correctly they act on each other in unexpected ways. I've not reached as far as using them correctly! I think it's something to do with which datum line or face they count.

.

One thing I did too, was browse through the further sections to see if I could twig this "synchronous / ordered' thing; since we are told to use the former, default, mode without explanation right from the start.

Syn chronos means "[at the] same time", moving or timing "together" .

Hence my original thought of facilitating networking and simultaneous file up-dating. SolidEdge might have such features, but under other names.

Then perhaps a drawing tool that allows entities related numerically to be modified or moved together with just one of them. E.g. change a regular polygon's size and its inscribing or circumscribing circle automatically follows; and vice-versa. Or when designing gear-trains, changing the pitch-circle automatically changes the accompanying circles to match. Even more versatile if you could also enter the linking information to suit specific tasks. (Does SE have a polygon tool other than squares?)

No….

Something to do with drawing solids. And I was none the wiser.

This is not something dragged over from TurboCAD because that does not use them. Rather, it's the way Siemens has used the word that is confusing because it seems to bear no relation to its real, "same time" meaning.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Model Engine running just off a naked flame

Started by:

Blue Heeler

in: Stationary engines

Blue Heeler

in: Stationary engines

- 5

- 12

-

21 July 2025 at 02:53

Blue Heeler

Blue Heeler

-

My vise isn’t at 90 degrees

Started by:

moonman in: Beginners questions

- 14

- 18

-

21 July 2025 at 01:19

Kiwi Bloke

-

Lidl castors

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 4

- 4

-

21 July 2025 at 00:41

howardb

-

Hofmann Rollers

Started by:

Martin Kyte in: General Questions

- 7

- 9

-

21 July 2025 at 00:30

gerry madden

-

Hopeless…Alibre Ass

Started by:

Nigel Graham 2 in: CAD – Technical drawing & design

- 4

- 12

-

20 July 2025 at 22:05

Diogenes

-

Redwing Cylinder head

Started by:

Durhambuilder in: I/C Engines

- 2

- 2

-

20 July 2025 at 21:41

grubscrew

-

What Did You Do Today 2025

1

2

…

8

9

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 33

- 202

-

20 July 2025 at 21:39

Dalboy

-

Polishing compounds for stainless steel (mild abrasives))

Started by:

Simon Williams 3 in: Beginners questions

- 13

- 14

-

20 July 2025 at 20:02

Russell Eberhardt

Russell Eberhardt

-

Bad design, or am I missing something?

Started by:

half whit in: Beginners questions

- 5

- 7

-

20 July 2025 at 19:16

Julie Ann

Julie Ann

-

Mistry dividing attachment

1

2

Started by:

Brian Merrifield in: Workshop Tools and Tooling

- 17

- 42

-

20 July 2025 at 18:43

Tony Jeffree

Tony Jeffree

-

Epoxy or acid etch primer

Started by:

Michael Callaghan in: Materials

- 1

- 1

-

20 July 2025 at 16:46

Michael Callaghan

-

Diving in to ATC?

Started by:

Steve355 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 4

- 6

-

20 July 2025 at 16:20

Martin Connelly

Martin Connelly

-

Measuring a double Vee lathe bed Vee position

Started by:

Kim Garnett in: General Questions

- 11

- 22

-

20 July 2025 at 15:51

Kim Garnett

-

Please direct me to where I can find an engineer to do some bespoke work

Started by:

srb1 in: Beginners questions

- 6

- 10

-

20 July 2025 at 15:43

Craig Brown

-

Making Unimat DB/SL Steadies

Started by:

Andy Carlson in: Workshop Techniques

- 3

- 4

-

20 July 2025 at 15:35

Andy Carlson

-

Alternative to ARC

Started by:

petro1head in: General Questions

- 4

- 8

-

20 July 2025 at 13:31

JasonB

JasonB

-

Sat nag

1

2

Started by:

duncan webster 1 in: The Tea Room

- 24

- 50

-

20 July 2025 at 13:18

Nigel Graham 2

-

Which lubricator do I need

Started by:

Michael Callaghan in: Locomotives

- 3

- 5

-

20 July 2025 at 12:45

Michael Callaghan

-

Advice to machine stationary engine base plate

Started by:

Greg H in: General Questions

- 5

- 12

-

20 July 2025 at 11:37

Greg H

-

Paint stripper does not do what it says on the tin

Started by:

Greensands in: Hints And Tips for model engineers

- 8

- 16

-

20 July 2025 at 11:11

Taf_Pembs

Taf_Pembs

-

Easiest/cheapest source of R8 socket

1

2

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 14

- 27

-

20 July 2025 at 11:01

Tony Pratt 1

-

Hofmann

Started by:

Matt Smith in: General Questions

- 2

- 2

-

20 July 2025 at 10:37

Tony Pratt 1

-

Even the Dealer Didn’t Know!

Started by:

Chris Crew in: The Tea Room

- 15

- 20

-

20 July 2025 at 07:54

Nealeb

-

Boxford paint colour

Started by:

Pete.

in: Workshop Tools and Tooling

Pete.

in: Workshop Tools and Tooling

- 5

- 10

-

20 July 2025 at 01:21

Pete.

Pete.

-

More BBC Masterchef woes…

Started by:

Nigel Bennett

in: The Tea Room

Nigel Bennett

in: The Tea Room

- 6

- 6

-

19 July 2025 at 22:55

Nigel Graham 2

-

Model Engine running just off a naked flame

-

Latest Issue

Newsletter Sign-up

Latest Replies

)

)