SE (CE) – Any Manuals Available, Please?

SE (CE) – Any Manuals Available, Please?

Home › Forums › CAD – Technical drawing & design › SE (CE) – Any Manuals Available, Please?

- This topic has 61 replies, 11 voices, and was last updated 24 August 2022 at 22:21 by

Nealeb.

-

AuthorPosts

-

18 August 2022 at 01:19 #610127

Nigel Graham 2

Participant@nigelgraham2As the title…

Printed please, or at least pdf ones that I can actually edit into a printable form.

Not videos. I cannot learn anything from videos..

Reason?

Some while ago, after uprating my copy of TurboCAD I studied various comments on this forum and thought SolidEdge (CE) might offer a better, more friendly and more learn-able CAD system than TurboCAD.

So I installed it .

I don't want to draw just pretty pictures, not even the beautiful, joint-free renderings TC allows you to produce on a 3D "model" relatively easily. Nor am I interested in ISO-rhubarb diktats on title-box fonts and hot-glue symbols.

What I do want, is to be able to make all three of direct orthographic drawings for making the parts, 3D assembly drawings (or "models" in CAD-ese); and elevations derived from the models.

TC allows both 2D and 3D modes as options when starting a new drawings; but though I have developed a rather low skill with big gaps in the 2D option, 3D is just impossible, and seems to offer no 2D derivation anyway. (Or I cannot find it.)

On the other hand….

TurboCAD offers a big range of "Save as" file options, and allows you to print the drawings; although its printing system is nightmarishly difficult, with no WYSIWYG or scale guarantee.

SolidEdge offers only one file-type (.asm, its own); and does not even mention "print" on any of its arcane tool-bars. The "P-word" does appear in the on-line 'Help' menu, but so mixed up with "managed environments" and other Silicon Valley puffery that it seems not the business of anyone daft enough to want a real drawing above the lathe or bench.

.

Another user here sent me a simple SE exercise: a rectangle with a notched corner.

Following that, I tried a slightly bolder T-nut. I created its end profile – several lines that might be a closed polygon but if not would be useless in a serious drawing where you may need copy or move the shape several times. I am not even sure if it is in 2D or a 3D extrusion base, but it does lie at an odd angle across the screen. The "extrusion" tool is anyway all mixed up with more jargon, so perhaps the wrong one of only one extrusion command.

And that were it…. Stuck. Nothing on SE itself to help me.

Stuck until this evening some months later, when I thought I'd try again.

And stuck again.

SE (CE) may prove simpler to use than TurboCAD for similar performance. I do not yet know, but it is far less intuitive despite better menu annotations. Also, as I say appears not to offer any printing, not even as difficult as its rival's print system. Perhaps Siemens assumes that a hobbyist CAD user is interested only in pretty pictures of things, not making the things. (TurboCAD used to advertise in ME- with the outright assumption of using the drawings in the workshop!)

If I can't find any literature, though, my only option is to delete the programme from the computer.

18 August 2022 at 01:19 #21395Nigel Graham 2

Participant@nigelgraham218 August 2022 at 08:33 #610144David Jupp

Participant@davidjupp51506Perhaps slightly dated as it seem to be from 2011, but is free and detailed (PDF including some exercises).

Solid Edge fundamentals (siemens.com)

A quick web search found a few training books for Solid Edge – fairly expensive though

18 August 2022 at 08:40 #610146 JasonBModerator@jasonbPosted by Nigel Graham 2 on 18/08/2022 01:19:06:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 18/08/2022 01:19:06:Also, as I say appears not to offer any printing, not even as difficult as its rival's print system. Perhaps Siemens assumes that a hobbyist CAD user is interested only in pretty pictures of things, not making the things. (TurboCAD used to advertise in ME- with the outright assumption of using the drawings in the workshop!)

Go back and look at the several other threads you have about CAD, You have been told SE will produce 2D drawings from the 3D model numerous times as will all the other 3D brands.

Or just find a manual online, this pdf shows how to get from 3D to 2D drawings

Edited By JasonB on 18/08/2022 08:45:04

18 August 2022 at 08:50 #610147lee webster

Participant@leewebster72680I still keep the Solidedge installation file, but I deleted the programme from my computer. It has to be on the same level as FreeCAD for awkward menus. I found it cluttered and messy.

Producing a "technical" drawing isn't important to me. I can produce a usable detailed drawing of my designs with Designspark Mechanical. My drawings can be of any angle of 3D view, or face on to any side of the part, even cut-aways. It is far from perfect, basic even, but fairly easy to use.

Lee

18 August 2022 at 10:39 #610171Nigel Graham 2

Participant@nigelgraham2Jason –

I am afraid you have missed my point.

I know advanced CAD systems offer 3D-derived elevations.

I mean printing the drawings, 2D and 3D, on paper, for real use. My PC is in the front room but the non-CAD/CAM workshop is down the garden and no place for a delicate computer!

.

TurboCAD lets you print the drawings – if you can understand how. It also offers many standard CAD and photographic file formats for saving your work for use on other software.

You can even save and print save a selection from the "Model Space" drawing directly, but this avoiding the official "Viewport" and "Paper Space" printing labyrinth loses the scale control (a gamble anyway).

The examples I posted on this forum are .jpg copies of the original .tcw files, made within TC.

'

Does SolidEdge (CE) have any printing facility or alternative file types? No menu on its tool-bar mentions either. Its Help site refers to fully professional, high-level IT systems. The full Solid -x versions do allow printing – I knew that at work, even before I tried any CAD package myself.

'

I failed with Fusion 360 and Alibre so do not know their file-type and paper-printing options, if any. At least Fusion does (or did) allow file-saving locations other than the Internet it tries to enforce. (Other people have asked about that point.)

'

David –

Thank you for that. I will investigate…

I would think that the basic programme will not have changed too much since 2011, just absorbed more bells and whistles I'd probably not need anyway.

.

Lee –

I have thought SolidEdge not cluttered, but difficult to navigate.

You'd certainly call my TurboCAD screen cluttered, and I find it so at times; but it has a beautifully simple way to select individual tool-bars and turn them on or off as wanted, from a neat and easily-reached tick-box index.

It's just a shame IMSI is incapable of writing an equally straightforward, properly-indexed 'Help' site! (I used copying, 'Word' and 'Excel' to create an alphabetical index for my TurboCAD 19 'Help'.)

.

I think that some of the "student" , "hobby" , "trial" etc. versions of many CAD programmes are published assuming that the image is the end, not the means to a physical end. Useful for learning CAD, but otherwise thought as just an art medium. They are subsidised by the huge industrial costs of the full engineering and architectural versions.

IMSI probably led the way with simpler but still full editions of TurboCAD's combined engineering and architectural packages with very powerful rendering and direct-printing tools, at sensible, one-off prices. The publishers of Solid-x and Alibre have had to catch up; and if SE(CE) has no printing facility, perhaps Siemens has not yet caught up!

18 August 2022 at 11:23 #610178SillyOldDuffer

Moderator@sillyolddufferI empathise with Nigel's problems because I've hit them too, but I think I make progress with CAD when Nigel gets stuck because I realised early on that previous drawing experience gets in the way:

- When 2D-CAD appeared, quite a few experienced drawing board draughtsmen couldn't cope with it. They expected the software to work in much the same way as a manual board, and it only does to a degree. Failing to realise 2D-CAD did the same job, and much more, but in a different way, leads to humans trying to bend a computer program to their will and they have no chance of winning! Computers have infinite patience, and – being programmed, can't change how they work. The human has to change.

- Same difficulty converting from 2D-CAD to 3D-CAD. 3D-CAD introduces yet more new concepts and ways of doing things that earlier experience doesn't help with. Again, there are examples of fully competent 2D-CAD draughtsmen being unable to transfer to 3D working.

- And the same problem occurs switching between different vendors. Although FreeCAD and Fusion360 take a similar approach to modelling under the bonnet, there are a multitude of differences in the way commands are organised and exactly how they work. And FreeCAD supports several different modelling workbenches whilst Fusion concentrates on Mechanical engineering and is much more developed. Although knowing FreeCAD helped me learn Fusion, I constantly had to remind myself that Fusion was different, and that I had to adapt to it. Solid Edge is different again. I've not attempted to learn TurboCAD, but the tutorials I've studied show it to be very different. For this reason I think it's a mistake to hop between packages in hope of finding an easy one – it's confusing!

How Solid Edge prints is an example of a different approach. For ordinary screen to paper printing, I looked long and hard for a print menu or print button, nope! All that's necessary is to type ctrl-p, which is a standard keyboard short-cut. Pathetically easy when you know how. Making 2D-drawings from a 3D model took a bit of finding too! I expected SE to work like Fusion and FreeCAD where 2D drawings are created fairly obviously from the model. It doesn't! Instead, SE requires the user to open a different document type (a specialised 2D type), which reveals the necessary commands. In SE 2D drawings are made by importing 3D models rather than exporting them with 3D command as previous experience misled me to expect. SE achieves the same result and it's not difficult, But SE achieves it differently, which has to be painfully learned.

I like Solid Edge very much, but didn't find it easy to learn. Probably the main reason was the need for me to unlearn other software!

I don't recall a post that quantifies how much effort is needed to become fluent in a CAD package. Hundreds of hours. In the early stages learning the ropes dominates and nothing complicated should be attempted until the basics are understood. Then, bit like riding a bike, more time is spent on the design rather than struggling with the software. After that it gets easier, but attempting advanced work often exposes there's still a lot more to learn.

I think Nigel needs a tutor rather than a book. Someone to show him the basics and highlight misunderstandings immediately. I suspect Nigel gets the software to display something that looks correct but is flawed. When he tries to build on it, the flaws bite and nothing works as expected. For example, Nigel mentions his sketch being on screen at an odd angle. I think this is an immediate issue because it's important to get the drawing plane or face right in all CAD and extra so in Solid Edge. The understanding and method have to be nailed before going much further, and it's a bit fiddly. An expert explaining, answering questions, and pointing out mistakes would take about 10 minutes. When I started learning SE I was aware of the need to fix it, but not sure how, and kept coming back to the issue over a week or so until I cracked it. Obvious now, but not at the time.

Dave

Edited By SillyOldDuffer on 18/08/2022 11:24:49

18 August 2022 at 11:44 #610186 JasonBModerator@jasonb

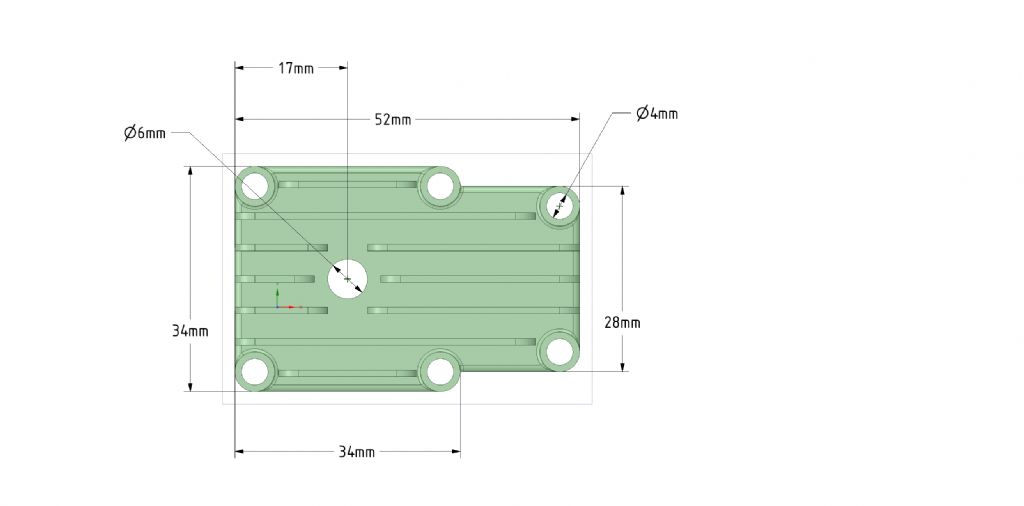

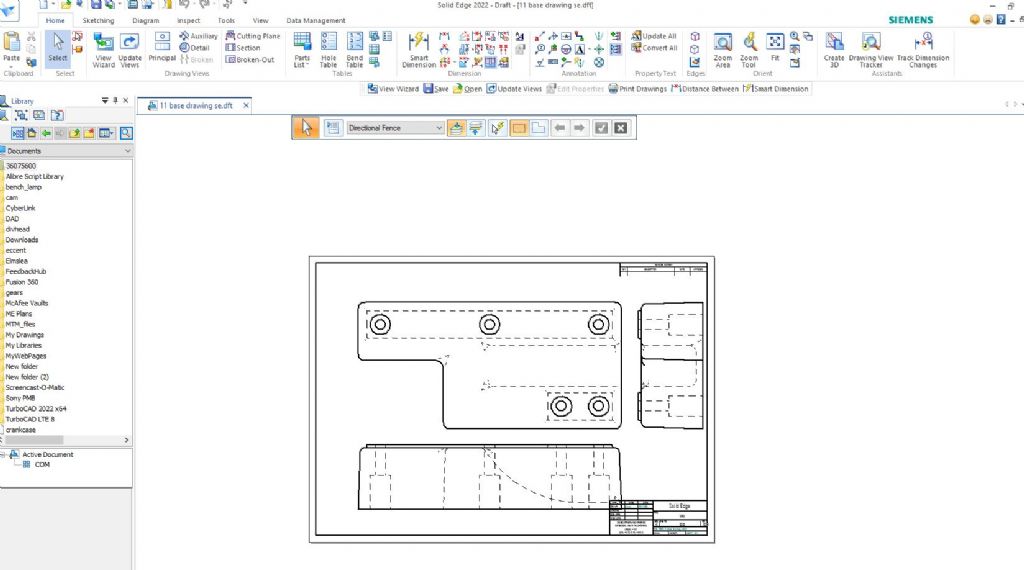

JasonBModerator@jasonbWell I suppose some people can get on with computers and others can't. I have just downloaded SE-CE did not watch any tutorials or video and in less than 5mins had imported a 3D model I'd drawn yesterday in Alibre produced a drawing of it with three 2D views and printed it.

Here it is as a PDF, could have sent it straight to paper printer or made a jpg as well as the usual DXF and DWG files

Or a screen shot

Edited By JasonB on 18/08/2022 12:06:42

18 August 2022 at 11:58 #610190Nealeb

Participant@nealebAs SOD says, experience with other CAD packages doesn't always translate directly. I've been through TurboCAD (where I found 3D to be next to impossible), OnShape (possibly easiest to use but least powerful at the time), Fusion 360 (good, CAM really useful, but I found problems once models/assemblies became complex) and now SE – very powerful but somewhat intricate to use and takes a bit of learning. These days, I model and (if needed) produce drawings in SE but export to F360 for CAM/CNC use.

In brief, with SE(CE), the process for producing printed conventional drawings is fairly easy but maybe not intuitive.

Have your model open on the screen. Right-click on the component in the LH list which shows all the sketches, etc, that have gone into the model. Select "create drawing…" and you will be presented with a blank sheet with title box which lets you position your component on it. You can add further views, including isometric, at this point. Use the dimension tool to add all the dimensions you wish (including baseline/incremental measurements if this suits your way of working).

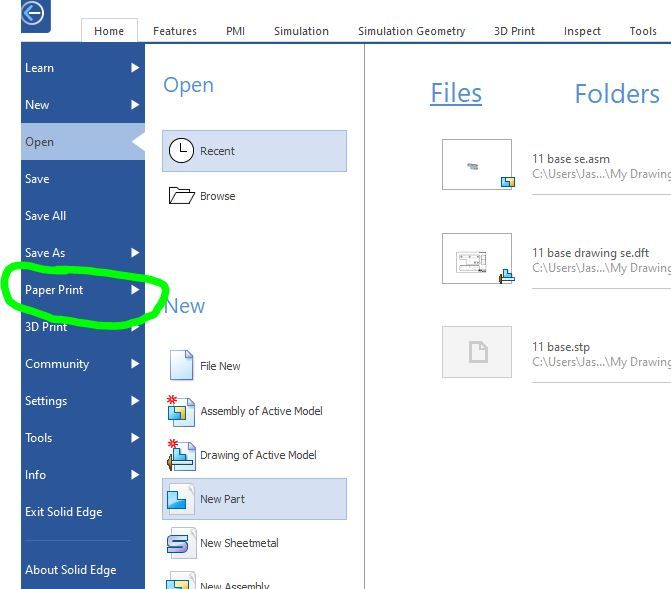

Once you have the drawings/views wanted, click the very top LH button on the menu (with the SE logo on it). From the LH menu, select "paper print" and you can then choose to print directly to a printer, or save as PDF format for later use. I have just checked this with SE 2022; not sure if it is true for earlier versions.

18 August 2022 at 12:09 #610194David Jupp

Participant@davidjupp51506It helps if the question is asked simply and clearly. Looking back the original thread does mention 'print' in passing, but I'd never have guessed it was a major problem. It was all buried within many unrelated moans. Sorry Nigel but after all your previous threads on CAD I tend to skim what seem to be repeated diatribes about how awful the products are and that none of us understand.

Perhaps a simple – 'I can't see how to print my 2D drawings to paper from SE, can anyone help?' would have been clearer…

18 August 2022 at 12:12 #610195Nick Wheeler

Participant@nickwheelerI agree with Dave, and have written this every time Nigel complains about software not working the way he thinks it should: he needs someone to stand behind him and explain how to model a part – an simple assembly would be better – that he already understands like a QCTP or single cylinder oscillating engine. That would immediately show his misconceptions of how 3D CAD works and direct him down a more useful path.

I do agree that computer programs employ tortuous language: SE help constantly talks about 'syncronous' modelling but makes no attempt at explaining what it means and why it is/isn't preferred. That's a common mistake for a lot of instructors who often make a simple concept seem far more complicated and technical than it is. Nigel has fallen into this hole and has been enthusiastically digging himself deeper for some time.

18 August 2022 at 15:43 #610223Nigel Graham 2

Participant@nigelgraham2I am well aware of the common traps like trying to compare more than contrast different techniques.

I never thought CAD as an electronic version of a manual drawing-board. I always saw it as basically lots of graphs – the programme does all the maths from the values I give it.

I did find it harder, when trying to look into SolidEdge as a possible replacement for TurboCAD, to avoid thinking in TC ways. Probably, all CAD works in similar ways behind the screen, especially on the same electronics, but the approaches and tools differ too much between packages to think in parallel ways. Even so, it does take an effort to realise the common features familiar on one, do not necessarily act in the same ways or have the same tool names on another.

'

David –

My original question was for a manual for the programme generally; but I did use being unable to to print a drawing, as an example.

In fact SolidEdge stopped me long before that, but I did search it for "Print". TurboCAD has a clear "Print" tool, but a very complicated procedure. All other software I have seen that can give you a print, makes the routine very easy to find, even if not always to use.

.

Nicholas –

I don't try to be too clever. My TurboCAD library still holds simple, random exercises to try to understand particular tools, for example to "drill" a hole through a rectangular block.

If I find it not working as expected, the tool or technique might not be intuitive anyway; but probably needs a prior step I have missed, I've used the wrong one, or I've misunderstood its use, through having nothing to tell me.

I do not have "misconceptions of how 3D CAD works" – simply cannot understand how to make it work. Yes, such skills are best taught personally, just as helping someone use a lathe; but that is not always possible.

In this respect though, I don't think it fair to criticise Siemens, say, for not explaining terms like "Synchronous modelling" because they might see it as a general industrial-CAD concept taught in professional engineering courses.

Regarding assembling drawn parts of an engine or tool-post; yes, I of course I want to know how to do that; but I need be able to draw the components first. Even just for a tool-post, long before very advanced drawings such as for my steam-wagon engine.

18 August 2022 at 16:01 #610227 JasonBModerator@jasonbPosted by Nigel Graham 2 on 18/08/2022 15:43:50:

JasonBModerator@jasonbPosted by Nigel Graham 2 on 18/08/2022 15:43:50:In fact SolidEdge stopped me long before that, but I did search it for "Print". TurboCAD has a clear "Print" tool, but a very complicated procedure. All other software I have seen that can give you a print, makes the routine very easy to find, even if not always to use.

It's fairly clear in SE-CE "paper Print" should be clear enough.

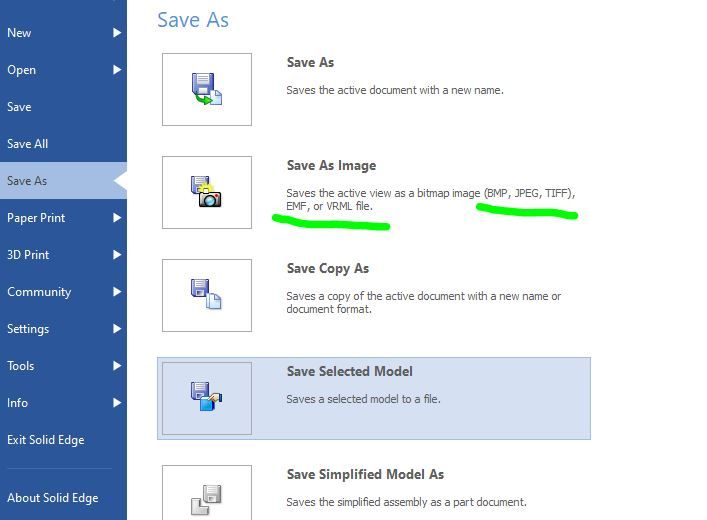

As for saving in other common formats that you say you could not find try this, jpg is in there and can be loaded to your phone to view in the workshop or easily printed out.

18 August 2022 at 19:08 #610275Nealeb

Participant@nealeb…and in SE, if all else fails, type what you want to into the "find command" box at the bottom of the screen. Helps enormously find functions that aren't in the current menu tab.

18 August 2022 at 20:26 #610286Nigel Graham 2

Participant@nigelgraham2Thank you Jason, Nealeb –

Have found it now.

I'd been looking in the "Data management" set that includes "Save As" etc.; similarly to most software running in 'Windows', and not realised the significance of the button with the star trade-mark.

I have also both down-loaded, and book-marked, the Siemens manual you cited above.

'

While I had SE open for this I performed an experiment.

I opened one my few 3D drawings in TurboCAD – a sliced cross-head with the two halves and the pin moved a little apart – and made a couple of copies in formats I thought transferable.

Then tried to open them in SE set to 3D Sketch.

I knew it would probably lose formatting details like line colour, but it also flattened it! The View Cube showed it slimmer than Twiggy sideways on – just a line.

So I was on the right track but had probably not selected the right file-type. Studying both systems' file options should show the common one(s).

18 August 2022 at 21:15 #610299IanT

Participant@iantEvening Nigel,

Let me take you back to this thread in October 2021.

Solid Edge – Community Edition | Model Engineer (model-engineer.co.uk)

As you may recall, I tried to explain how best (in my experience) to get going in Solid Edge. It's a little while ago now but I think it will still all be valid if you decide to work through it all. There's even a reference (link) to some very comprehensive PDFs (that Siemens describes as self-paced learning) that can also be used as a set of manuals.

It will take you some time and effort to work through my recommendations but I'm afraid I don't think there are too many short cuts – you have to approach any 3D CAD system methodically (and not just try dipping in here and there). You may of course have some success with the 'jump right in' method but you will also fall into many traps and pitfalls along the way too. I made this mistake with TurboCAD a long time ago and for many years my ability to draw 2D drawings effectively was limited. It took Mr (Paul the CAD) Tracey to put me on the right path but it was hard to unlearn old (bad) habits that could (and should) have been avoided very early on.

So, if you are serious about learning Solid Edge, then please take the time to do it properly. I think you will find it a very good investment and help you to enjoy 3D CAD in all it's utlity and splendor !

Regards,

IanT

18 August 2022 at 22:09 #610308Nigel Graham 2

Participant@nigelgraham2Thank you Ian.

You did indeed, the upshot of it being that I was able to draw a rectangular block with some holes through it. I sort of fell apart after that, with both SE and TC.

With my drawing-board all in bits now as well, I have reached the stage of designing my project, a 4"-scale steam-wagon – on the fly: literally measuring bits of metal against each other and making a few rough old pencil sketches. Then re-making parts to correct the unforeseen "design errors" from months or years ago. If you want some carefully-drilled holes, I have plenty to spare, safely held in the chassis so they won't get lost.

It's advanced too far for CAD to help me design the rest beyond a few individual parts, because drawing the assembly even so far would need CAD skills well above my present level. Yet it was very much that project in mind that send me CAD-chasing in the first place.

My last CAD drawing was still little more than a digital sketch, to set up the blast-pipe and chimney…. only to find when I had machined a few pieces of brass that the two were out-of-line along the smokebox. That wasn't a drawing error but a machining error when I made the smokebox barrel – probably fifteen years ago!

' ' '

I can't find it now but I think someone suggested taking the drawing to the workshop, on my portable 'phone! That tickled me. Even if it is possible to transfer the image to it, I'd need a magnifying glass to read a complicated drawing on a screen the size of a Myford original cross-slide handle, and switching off every 30 seconds or so.

19 August 2022 at 07:00 #610324

19 August 2022 at 07:00 #610324 JasonBModerator@jasonb

JasonBModerator@jasonbDon't you have a zoom on your phone screen? works just like a magnifying glass by enlarging the image and I did also say that the JPG could easily be printed as another option to putting it on your phone

Only last week we had someone wanting to save drawing images so they could be put on their phone for workshop use. They had a happy outcome.

I've done it myself but just take a photo of the screen as it's quicker than saving as a jpg and then transferring to the phone.

Quite a few here seem to have an old tablet or computer in their workshops and I know of other that don't take paper drawings to the workshop but have it all on a 'puter including access to their CAD,

Edited By JasonB on 19/08/2022 07:04:11

19 August 2022 at 10:09 #610346Nick Wheeler

Participant@nickwheelerPosted by Nigel Graham 2 on 18/08/2022 15:43:50:Regarding assembling drawn parts of an engine or tool-post; yes, I of course I want to know how to do that; but I need be able to draw the components first. Even just for a tool-post, long before very advanced drawings such as for my steam-wagon engine.

I suggest that a real, on site tutor could lead you through the creation of such things to help break through your mental block. A QCTP block is just two fairly simple sketches and a couple of extrudes; the main rotating part is similar, but sketched in place(so all of the important dimensions transfer directly) and revolves for the solid. Add a joint and you have a working assembly. The piston is a simple rod and another joint. That's maybe 30minutes instruction but covers a lot of common concepts – components, bodies, joints, additional planes, use of symmetry, constraints and dimensions, creation of useful solids etc, etc

19 August 2022 at 12:03 #610386Nigel Graham 2

Participant@nigelgraham2" ….. zoom on your phone screen? "

" …put [the drawing] on the 'phone for workshop use…" ?

No! 'Fraid not!

Why do people who have all this latest electronickery, think everyone else has? I call it it the 'Great Family We-All'

Mine basic instrument is compact, pocket size of sports-shirt not just Barbour waxed-jacket dimensions. Volume control: Quite Loud to "WHAT DID YOU SAY? DON'T NEED TO SHOUT!" . Camera very simple: did not do justice to the "Britannia" I chanced to see in York Station. Calculator: too rudimentary for decimal-points and sins. Internet use: theoretically possible but no account, screen too small for practicality. Transferring images to it, as well as from? Possible – I don't know. It has a USB charger/data socket.

Text message use: clumsy but…

….. alarm clock effective – and here's the thing –

Telephone calls are its primary function,

not an auxiliary feature, for annoying everyone else breaking up on the train in a tunnel!

So no; no use in the workshop. The bearing-bush maybe, but the bearing housing would be illegible as a rigid 57 X 42mm, non-scrolling, portrait-only, image!

.

I have a large-screen, all-in-one, PC partly for CAD use; no lap-top or tablet; but as with books and magazines, I prefer printed drawings and information tables in the workshop as being simple, instant, direct and clear to read.

My previous, WIN-7, PC holds TurboCAD and most of my CAD drawings, and has a screen large enough for clarity, but is far too inconvenient for my cramped workshop. It won't fit anywhere!

.

The ability to use something is not always a reason to use it, by balance of advantage. Assuming no CNC machines anyway:

Use CAD for its technical advantages over manual drawing; and in the comfort of the front room.

Then put the instantly-readable A4 prints in clear plastic sleeves, needing no batteries or power-supply, taking negligible space and readily portable between any convenient locations in the shed! (Roof new or old….)

.

(I bought an HP OfficeJet 7510, A3 copier/printer for CAD use, and a planned future copying of a set of A3 drawings to an external digital archive. Good print quality, but otherwise a huge mistake.

Very noisy, automatic preparatory routine sounding like a dramatic breakdown, taking up to half an hour.

Uncertain paper-feed.

Prints on, but can not copy from, A3 sheets as its advertised specifications promised: copier surface far too small, possibly an obsolete American paper size. So useless for the archiving. Unfortunately I did not discover this until I tried the copying months after purchase, but I wonder if this made it legally, "goods not fit for purpose".

And naturally, absurdly small cartridges at absurdly excessive cost.)

19 August 2022 at 14:02 #610424SillyOldDuffer

Moderator@sillyolddufferPosted by Nigel Graham 2 on 19/08/2022 12:03:46:" ….. zoom on your phone screen? "

" …put [the drawing] on the 'phone for workshop use…" ?

No! 'Fraid not!

Why do people who have all this latest electronickery, think everyone else has? I call it it the 'Great Family We-All'

Mine basic instrument is compact,…

(I bought an HP OfficeJet 7510, A3 copier/printer for CAD use, and a planned future copying of a set of A3 drawings to an external digital archive. Good print quality, but otherwise a huge mistake.

Very noisy, automatic preparatory routine sounding like a dramatic breakdown, taking up to half an hour.

…

And naturally, absurdly small cartridges at absurdly excessive cost.)

Again I share Nigel's pain!

My A3 InkJet printer, no copier, was also a massive mistake. A3 photographs consume an enormous amount of ink and I rarely produced them. The printer did excellent A3 technical drawings, but either used black ink disproportionally quickly or made black by expensively mixing colours. In practice, most of my part drawings are A4, and I don't print them all that often. Most design work is done on screen, and only a single paper print in a plastic sleeve is needed in the workshop.

The way I used my InkJet was all wrong. To keep the jets and pipe work free, the printer needs to be used every day, otherwise the innards gum up. When the printer detects gumming, or perhaps assumes it due to infrequent printing, it pumps ink violently through the system and collects it as waste. Only then will it accept it's ready to spray ink on paper correctly. Compared with frequent printing were cleaning is minimal, infrequent InkJet printing wastes enormous time and ink.

InkJet was the wrong print technology for me, and I suspect many others. I switched to a black and while laser, much faster per page, toner is dirt cheap, and there's no wasteful clean cycle. Not perfect – A4 only and no colour. If I need colour or bigger than A4 I have to go to a print shop.

I don't own a mobile phone of any sort. No signal in my house.

It's a cruel world!

Dave

19 August 2022 at 14:19 #610429 JasonBModerator@jasonb

JasonBModerator@jasonbTwo posts not happy with cost of ink, you can buy a cheap 10" tablet for what a cartridge or two would cost and you could use that to take your drawings to the workshop.

19 August 2022 at 17:31 #610445

19 August 2022 at 17:31 #610445Nigel Graham 2

Participant@nigelgraham2Dave –

Aha! I wonder if you've identified why my A3 printer sounds as if it's breaking up when I switch it on! It's trying to clear its congested tubes.

Jason –

I take your point, Jason, but I was not thinking of cost in this context, but of physical practicality.

Whilst your solution may work for others it would be difficult and hazardous to the tablet to use it in my workshop, and there is really no-where even to put it next to the larger lathe or the milling-machine!. Whereas I can put a sheet of paper in a plastic sleeve and hang it from some convenient point, hold it with a magnet to something steel but well away from the swarf, etc.

(Ex-hard drive magnets are excellent for that – they usually clip all sorts of ephemera to steel cabinets in my kitchen!)

My printed drawings, apart from being rare, are now normally A4, made on an HP Deskjet printer that produces perfectly good results even on the lowest ink-saving setting.

'

There is another advantage to a printed drawing, of immediate accessibility if you need refer to it when the computer screen is occupied by a later drawing related to it. Even more so when you need work across more than two drawings; or perhaps look up a lot of data-tables like tapping-drill charts.

Yes, of course you can switch between them electronically, but that creates distractions and makes visual comparisons physically more awkward. It's not so much what the computer can do full-stop, but what it can do for you in the most efficient way in the particular situation. Consequently there are right by my PC, a Tracy Tools conversions and thread-date chart, a scientific calculator, sometimes a Zeus Book as well, and pen-and-paper.

.

Printed matter, however sophisticated the computer programme used in its creation, is also far more amenable to archiving even if just for our own use, e.g. to repair something we built two decades previously; or to form a boiler-test history.

Although no medium is safe from fire, floods, willful harm or that insurers' catch-all, the Act of God; no-one yet has devised any other storage medium easy and practical for anyone to use, but which can be still be read 10, 20, 100, even 1000, years hence; and by the same make and model of scanner and signal-processor; the Eye & Brain, Human, v.1 (Holocene).

I don't pretend any surviving drawings of mine will be sought after by industrial archaeologists in 2322 – puzzled over perhaps. Nevertheless, how many of us can be sure we will be able to retrieve our own electronic documents for our own use in only 2032? This struck me at work, by box-fulls of floppy discs no longer readable either by deterioration or the loss of the right sort of computers. Fortunately the reports from the test-results most of them had held, were safe in the consequent documents; on paper as well as any digital media.

.

As to my original question (SolidEdge literature), I will try again to overcome the "mental block" one or two think I have, and learn SE to a standard useful to me. I must accept it very unlikely I can progress much higher than I reached with TurboCAD; but it will achieve something just to design Part B to fit A so C co-operates with both and no bolt-heads jam in corners or overhang the sides!

It's a very simple block: I don't know how to use the wretched thing!

19 August 2022 at 20:34 #610467

19 August 2022 at 20:34 #610467IanT

Participant@iant" I don't know how to use the wretched thing! "

I don't mean to be unkind Graham – but nor will you until you decide to make the effort to actually learn it.

Go back to my original thread and within a few evenings you will have drawn a Micrometer in 3D CAD (something a bit more complicated than a block with some holes in it). You may not be fully au-fait with all the detail of how you did it but you will really have drawn it yourself (and have a CAD file to prove it) using the basic tools in Solid Edge.

I did this within a few evenings myself, knowing nothing about Solid Edge and whilst it didn't make me a Solid Edge expert (and I'm still not) – it did convince me that I could learn to use SE with a bit of practice. It's a matter of confidence.

So stop telling yourself (and us) all these reasons you can't do this – and get just get on and put the effort into trying to learn it!

Regards,

IanT

19 August 2022 at 21:49 #610471Nigel Graham 2

Participant@nigelgraham2I know, Ian! I was trying to refute the "mental block" charge.

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › CAD – Technical drawing & design › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

I’m Under Pressure

Started by:

howardb in: Related Hobbies including Vehicle Restoration

- 15

- 17

-

9 July 2025 at 22:39

duncan webster 1

-

Bosch PBD 40 bearing upgrade

Started by:

th1980 in: Manual machine tools

- 5

- 11

-

9 July 2025 at 22:00

th1980

-

Sat nag

Started by:

duncan webster 1 in: The Tea Room

- 11

- 20

-

9 July 2025 at 21:48

bernard towers

-

Farm Boy

1

2

3

4

Started by:

Dalboy in: I/C Engines

- 15

- 100

-

9 July 2025 at 20:58

Dalboy

-

Bearing boxes for ball race

Started by:

Paul McDonough in: Beginners questions

- 11

- 20

-

9 July 2025 at 20:38

old mart

-

Twin Engineering’s heavy mill/drill quill removal

1

2

Started by:

Martin of Wick in: Manual machine tools

- 11

- 34

-

9 July 2025 at 19:42

old mart

-

Easiest/cheapest source of R8 socket

Started by:

Beardy Mike in: Workshop Tools and Tooling

- 7

- 9

-

9 July 2025 at 19:31

old mart

-

New (but well aged) member

Started by:

mikemunson in: Introduce Yourself – New members start here!

- 5

- 5

-

9 July 2025 at 19:25

Howard Lewis

-

Transwave converter – plugged in motor, tripped RCD

Started by:

ell81 in: Beginners questions

- 7

- 9

-

9 July 2025 at 19:17

old mart

-

Square end on round stock – Milling?

1

2

Started by:

Roger TheShrubber in: Workshop Tools and Tooling

- 16

- 28

-

9 July 2025 at 15:39

JasonB

JasonB

-

File backup to external hard drive, incremental etc?

Started by:

Peter Bell in: The Tea Room

- 11

- 17

-

9 July 2025 at 13:50

Graham Stoppani

Graham Stoppani

-

Boiler Design – issue 4765

1

2

…

7

8

Started by:

Charles Lamont in: Model Engineer & Workshop

- 26

- 186

-

9 July 2025 at 12:28

Paul Kemp

-

motor and switch wiring Myford ML7

Started by:

1957jmh in: Workshop Tools and Tooling

- 3

- 4

-

9 July 2025 at 00:41

1957jmh

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 34

-

8 July 2025 at 23:53

Bazyle

Bazyle

-

Old plastic handled screwdrivers

Started by:

Dave Halford

in: Workshop Tools and Tooling

Dave Halford

in: Workshop Tools and Tooling

- 9

- 10

-

8 July 2025 at 18:48

bernard towers

-

Angle grinder woes

Started by:

Speedy Builder5 in: Workshop Tools and Tooling

- 5

- 8

-

8 July 2025 at 18:26

DC31k

-

in line oil check valve

Started by:

Garry Coles

in: General Questions

Garry Coles

in: General Questions

- 5

- 5

-

8 July 2025 at 18:05

salatipa

-

Chester Champion, warco ZX15 drawbar

Started by:

martian in: Manual machine tools

- 4

- 6

-

8 July 2025 at 16:49

martian

-

Bridgeport ways and wear

Started by:

inline in: Manual machine tools

- 6

- 17

-

8 July 2025 at 15:44

duncan webster 1

-

Drilling holes in blades?

Started by:

Bo’sun in: The Tea Room

- 8

- 20

-

8 July 2025 at 15:28

Bazyle

Bazyle

-

Need help choosing a lathe chuck

1

2

Started by:

th1980 in: Workshop Tools and Tooling

- 21

- 38

-

8 July 2025 at 13:30

JasonB

JasonB

-

After all these years … I fell for a scam :(

Started by:

Michael Gilligan

in: The Tea Room

Michael Gilligan

in: The Tea Room

- 4

- 6

-

8 July 2025 at 12:58

Robert Atkinson 2

Robert Atkinson 2

-

Bentley BR2 Rotary Aero Engine

Started by:

notlobgp14 in: Miscellaneous models

- 5

- 9

-

8 July 2025 at 10:42

peter alcock

-

Starrett and other tool manufacturer wood boxes

Started by:

Ian Owen NZ in: Workshop Tools and Tooling

- 12

- 19

-

8 July 2025 at 10:28

Ian Owen NZ

-

I found this old car but what is it?

1

2

3

Started by:

Buffer in: Related Hobbies including Vehicle Restoration

- 34

- 54

-

8 July 2025 at 10:17

matthewwatts

-

I’m Under Pressure

-

Latest Issue

Newsletter Sign-up

Latest Replies