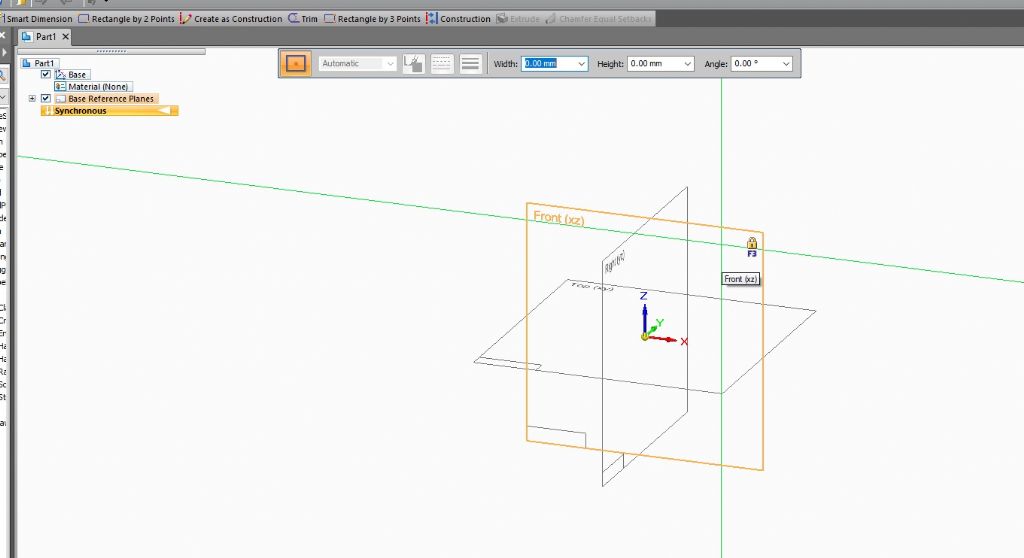

Your experience is very similar to mine when i picked Solid Edge back up after a decade or so of not using it (they changed from "Ordered" only to "Synchronous" being preferred in that time).

Initially it was like wading through treacle, but I kept pushing through and suddenly after a couple of tutorials and modeling some simpler parts of my own, it just clicked and it was all upward from there.

It probably doesn't help that Solid Edge has been rapidly gaining feature-sets all the time and is growing from its user friendly roots to be more and more of a full-featured professional CAD package aimed at medium sized organisations who don't need the complexity of Siemens NX, Catia or Pro/E, but do have a dedicated in-house design engineering office.

My experience is that the Siemens help is extremely comprehensive, and reasonably easy to search, but not always clear (my most frequent frustration is learning that there's a button to do exactly what I want, but not being given any indication as to where i would find this in the +10 ribbon menus that form the UI).

You should expect to have a similarly infuriating experience when you start using the assembly, sheet metal and weldment environments but that each of those will suddenly get much easier one day with some use.

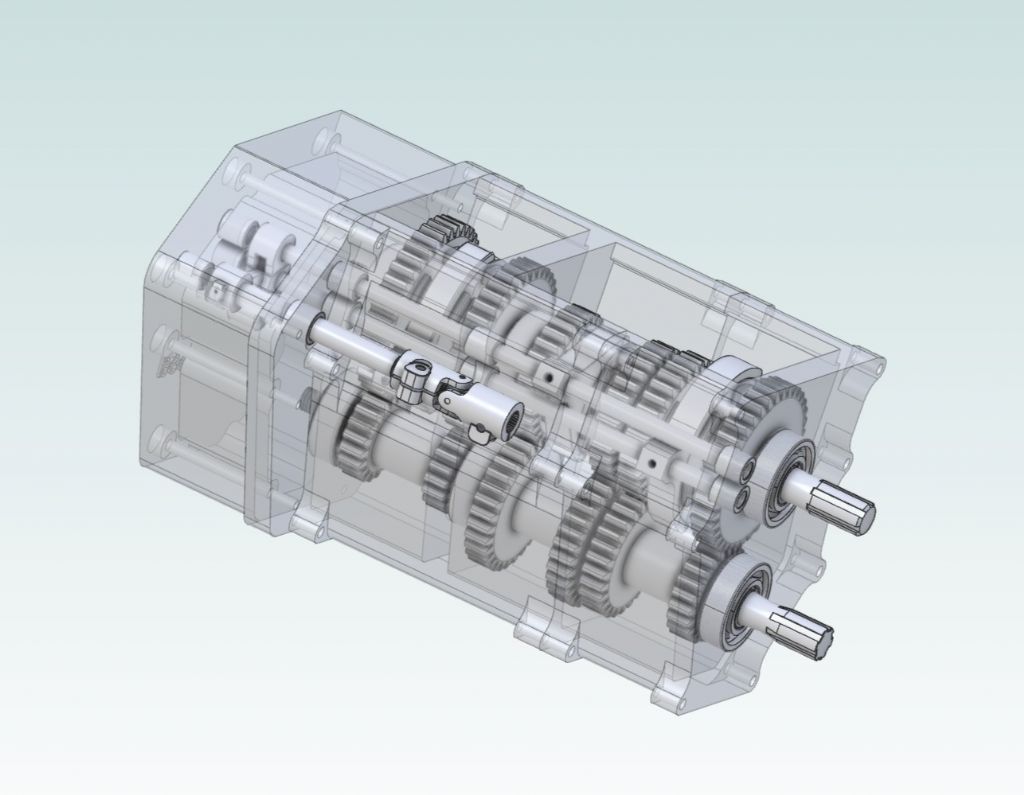

With respect to not being able to manage something like John's gearbox assembly, there's a (not very) secret…

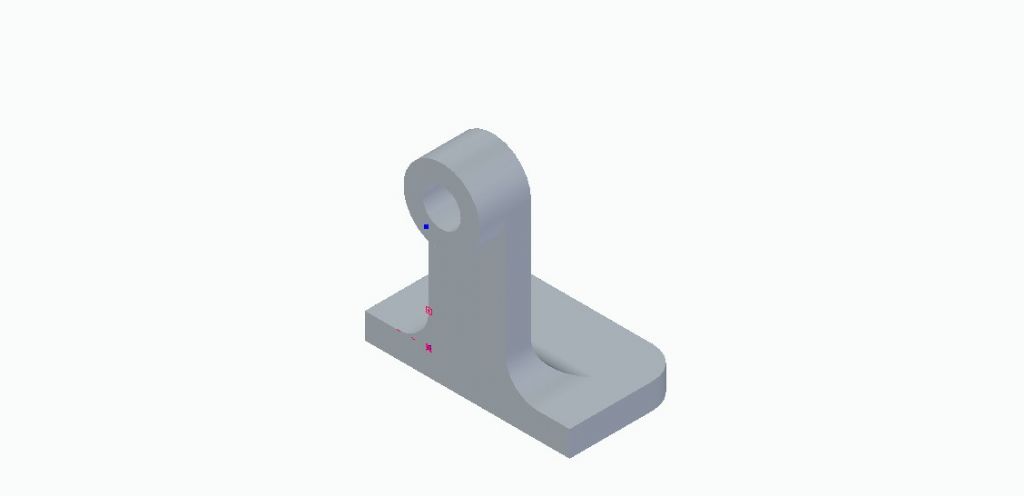

When I've modeled similar things in Solid Edge, using the engineering reference feature in the edge-bar for assembly mode to auto-generate parts (like gears) to established standards based on either dimensional (I want a Mod 4 gear with a PCD of "x"mm) or functional (I want a DP gear to give me a 2:1 ration at 1500 rpm and 2hp) inputs is usually my first step.

This makes it a lot easier to make those complex assemblies as you can start by generating and aligning the business end of the mechanism so it will work as required, then use that model of the functional parts as a reference to model the shafts, frames, bearing seats, bearings, etc. which will hold it all together.

In my experience you don't have to hold quite as much in your head all at once that way because you're getting the functional design decisions done quickly, then moving on to a new set of decisions about how you will manufacture a given assembly rather than juggling lots of competing decisions.

As a thought Nigel, If you find yourself getting stuck with something repeatedly and would welcome a second pair of eyes to help you get past a particular obstacle, drop me a private message and I'd be only too happy to arrange to go through a problem you're having on Teams/Zoom/[Insert Video-Conferencing Software of Choice Here].

I'm not about to claim to be an expert draftsperson or CAD modeller, but I have used SE for a long time now, to do some relatively complex design work for various research projects and am pretty confident with it.

Edited By Jelly on 20/09/2022 11:23:35

Edited By Jelly on 20/09/2022 11:24:11

Nigel Graham 2.