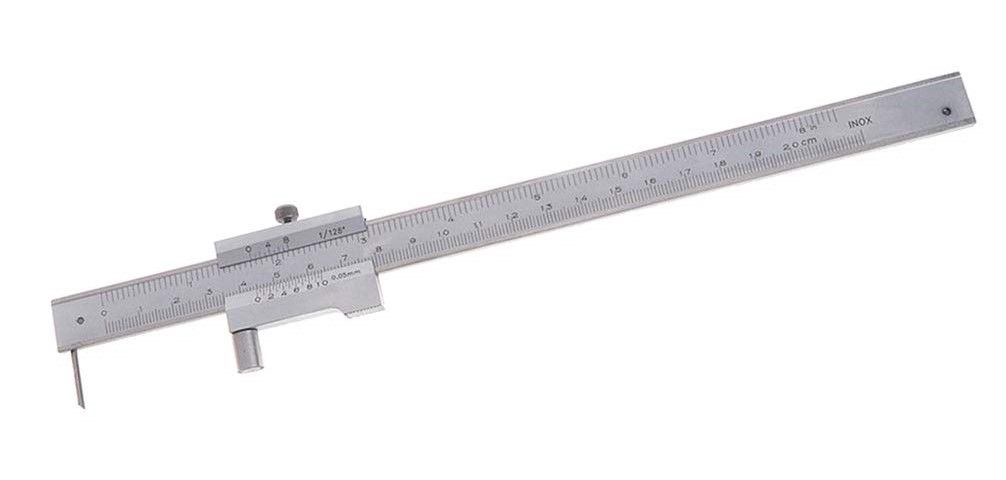

The risk with using Callipers, free hand, is that they will not remain "square" to the workpiece at all times, and so render a less that accurate or straight line.

Ideally, the "tool" to use is a Height Gauge, which will have attachments specifically for scribing.

This will ensure that the scribe is always the same distance from the edge of the workpiece (Assuming that it is clamped to an angle plate or something akin to it, on a known flat surface. Recently, to scribe some 6 mm x 6 mm x 23 gauge sheet steel angle, it was clamped to a 1/2" square HSS toolbit. )

As an Apprentice in the Toolroom, I was encouraged to make a base into which my Rabone Vernier Calliper could be mounted, a clamp, and and fittings so that it could be used for scribing or to carry a light DTI.

Effectively, this converted it into a small Height Gauge.

From time time to time articles appear on in the Model Engineering press on how to make such things.

For those lacking a Surface Plate, for the occasional small job, the bed of a machine or a thick piece of glass could be used.

It would be possible to use the marble cutting plates that are sold in Supermarkets, as cheap source, as long as they are correctly supported to be stress free.

I made a surface plate from a piece of marble, obtained from a stonemason, as an off cut from a grave headstone. It was about 40 mm thick and 500 x 600 mm, and cost £30.

It was bedded onto quite wet plaster, to ensure that it was not stressed, on ply, on an angle iron base, with cross reinforcements, and leveling feet at the corners.

Howard

File Handle.

File Handle.