Hi Andrew, I have the same machine, and you are right, it is annoying. But there is a quick fix.

On the fixed side of the vice – just turn the piece of sheet metal around – and you are there. Probably you need to grind away 1 or 2 mm from the edge not to touch the saw blade (This is what I needed to do)

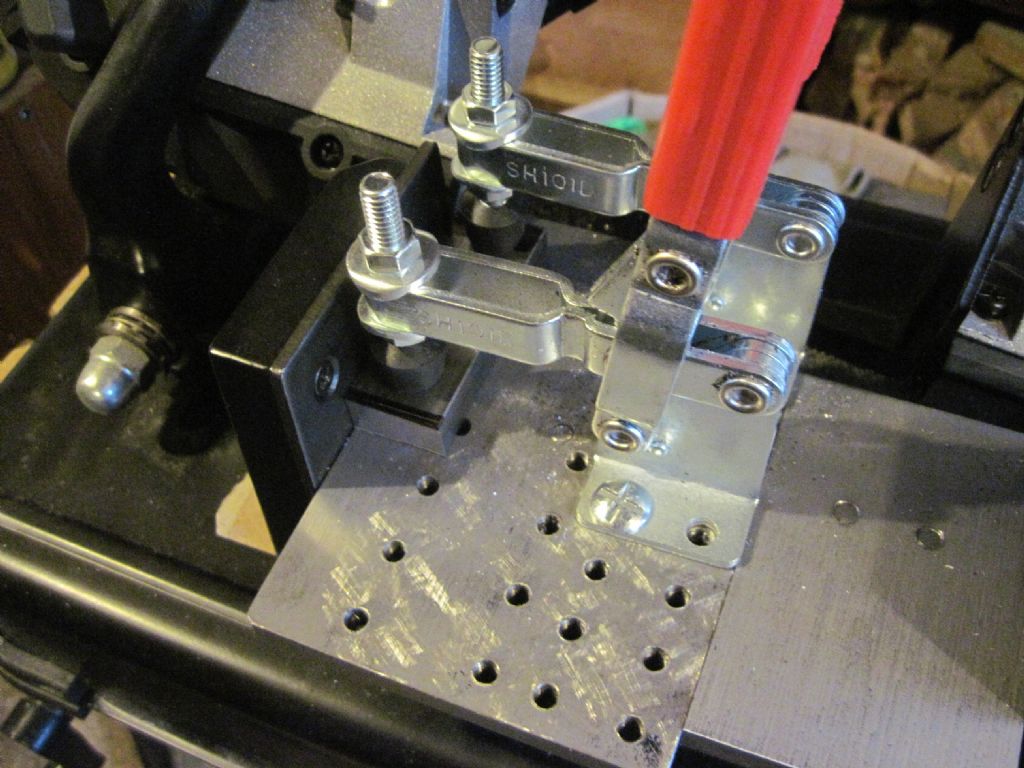

on the movable side of the vice I grabbed a piece of rather thick sheet metal I had in the bits box and screwed it to the existing jaw (of course you need a few holes and thread them n the existing part)

If somebody asks why the additional jaw doesn't reach the end of the original jaw – I said the part used is from the bits box and I didn't have any other, longer part. On the next photo you see that you are almost touching the sawblade. So – problem fixed, took me about one hour to do it.

By the way I do love the saw, after a proper set-up it saws absolutely 90 degrees to the vice. This allows me to go close to the final dimension I need and this helps saving time (less filing or milling…)

Edited By Gerhard Novak on 23/01/2022 12:20:08

Keith Matheson.