Peter, you can scale any model to your desired size but as others have said various factors need to be taken into account beforehand.

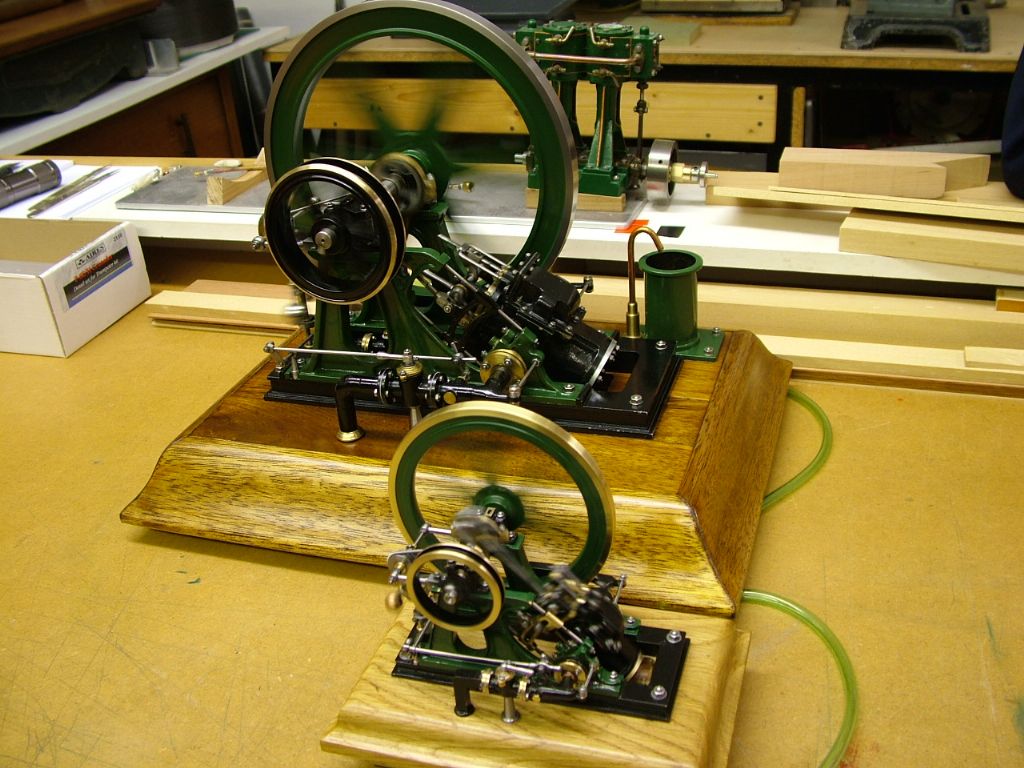

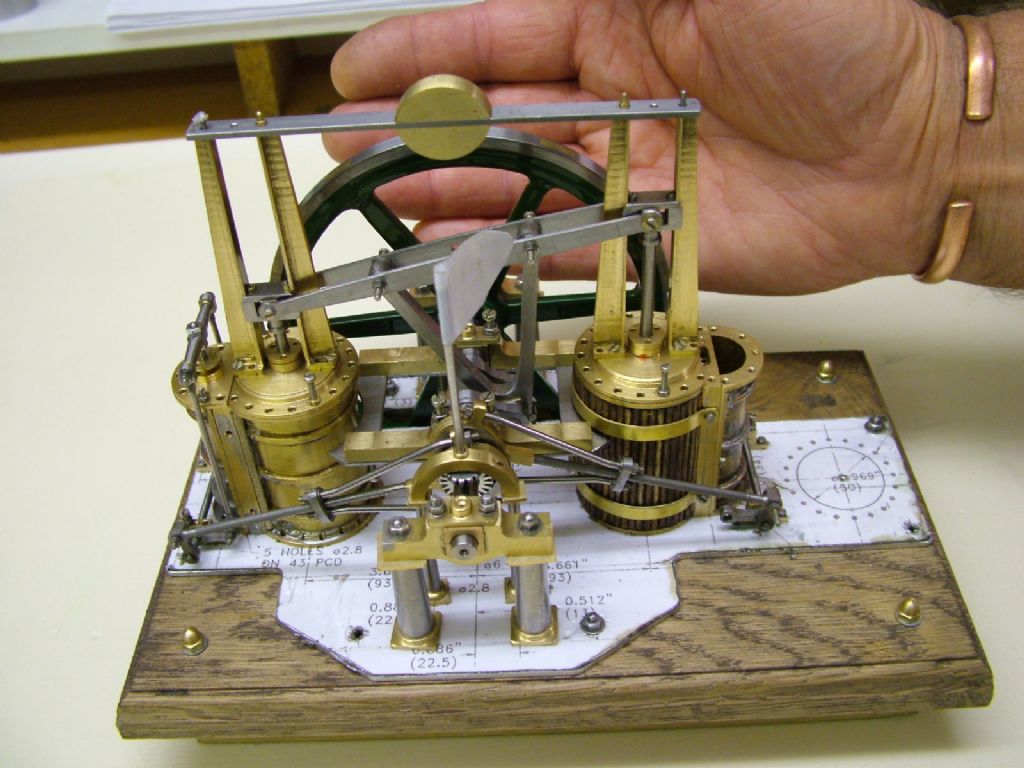

As Jason I have scaled several model projects – commercial 2.5cc model aircraft engines to a constant 5cc for example and an Anthony Mount Waller Engine to 1.333. Currently I am working the other way and building a marine compound engine to 5/8ths of the original drawing dimensions.

Something to take into account when going up is mass – a straight forward 'twice the linear dimension' will give eight times the volume for instance – quite an increase in material costs for a start. Heat absorption or retention is another if an IC engine or an engine running on steam.

Construction techniques is another – something adequate for the original size being overkill or inadequate for the scaled item, up or down.

Personally I would think of scaling (in your instance) as a percentage of the original and convert each dimension directly – and work to it – no rounding up or down on anything. Doing the latter quickly leads to having to change things to suit further on and usually, if not always, brings further problems down the line.

Castings are not always an essential – it's amazing what can be produced from stock material and JB Weld for instance. Plus the benefit of firm datums, soft homogenous cast iron if bought as such and no casting alignment problems either.

On that note "The world's your oyster" just pick your subject bearing the above in mind and go for it, there are some great designs out there that just beg for being made a bit larger or indeed a tad smaller.

Best – Tug

Edited By Ramon Wilson on 15/11/2022 16:56:47

Tim Stevens.