Posted by Philip Borland on 24/09/2022 11:18:59:

I have spent a little time researching on YouTube and it would appear that a much larger pitch is required for a vertical bandsaw. A couple of them show 4 TPI, which is much greater pitch than I have tried in the past – but it co-insides with the advice above about the Tuff-Saws.

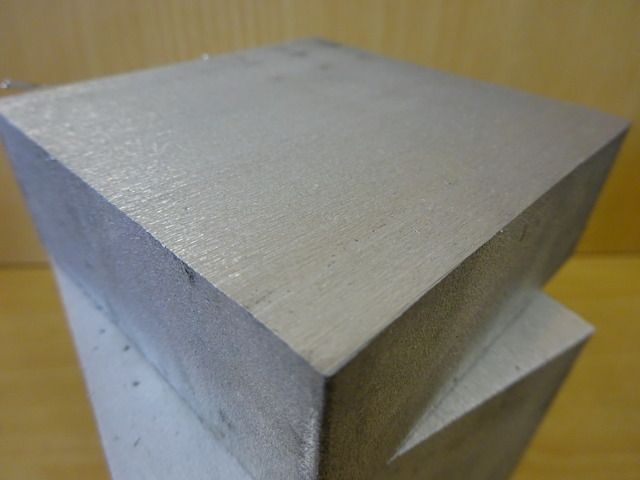

What TPI would you recommend for 10mm Aluminium plate ?

What would you use for Mild Steel ?

My experience has been that TPI is more or less set by workpiece thickness independent of material, so it would be the same for both.

If you're cutting aluminium then you will be fine with the cheaper carbon steel blades, and may get away with using a wood blade if you want to chance your arm to get it done quickly.

Tuff-Saws also has a handy reference guide on choosing metal cutting bandsaw blades buried on their website; which I often use that as the starting point when selecting a blade (I keep a bunch of them on a hook, but can never quite remember what's most appropriate for what, I should probably put a chart behind the hook).

In practice you can "get away with" using a blade which is a bit finer than is really ideal most of the time, but not using too coarse a TPI on a thin workpiece (noise, terrible cut quality, broken teeth, blades jumping off bandwheels, etc.) So I would err to the finer side of what's considered appropriate if you're just buying a blade for a one off job.

Edit: accidentally linked to a vacuum cleaner on EBay rather than the reference page.

Edited By Jelly on 24/09/2022 12:07:33

David George 1.

David George 1.