Peter,

I have found a picture! On the original you can zoom in and just see the JW but you can't read the number (it's actually 38 not 68 as I thought!). The number is just below the bottom row of stays, just above the foundation ring and just right of centre. I don't know if you will be able to zoom in and see it on the uploaded version.

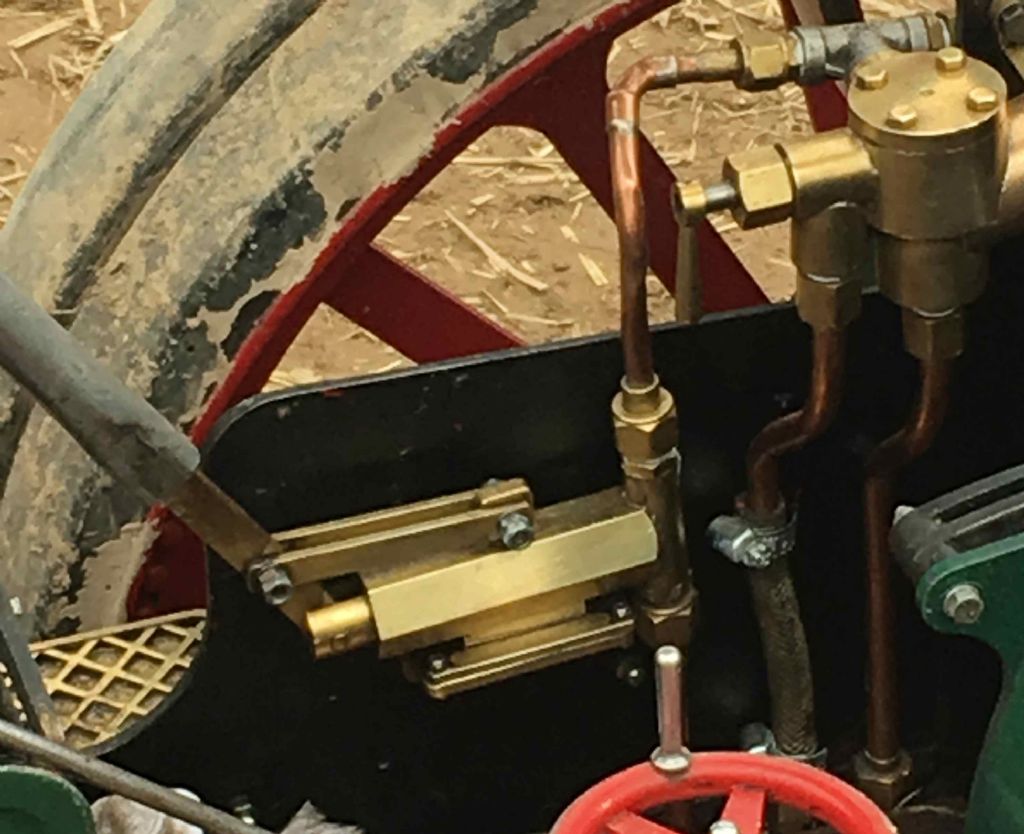

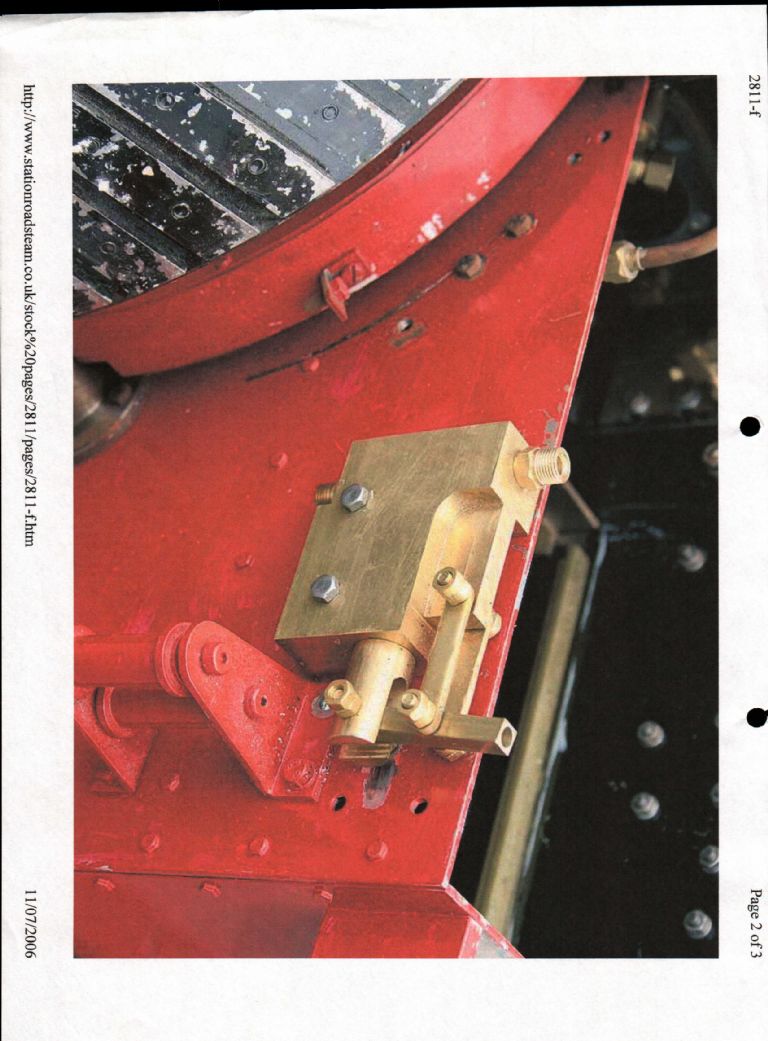

As to a hand pump……… Yes I have one fitted, it is mounted within the water space of the tender under the coal space. I have an aluminium 'box' that sits in the coal space to hold coal with a rubber sheet glued to the underside of the box forming a seal against dirt falling into the water space through the slot for the pump handle. The bypass for the crank pump is routed to the same position so I can see if I wish too that the pump is operating. The hand pump is teed into the crank pump delivery pipe downstream of the bypass valve so to use it the bypass must be closed.

Is it any good? Well that's subjective! My opinion is it is only really useful for filling the boiler from cold or for pressure testing it. I have never been in the position where either the crank pump or the injector have both let me down but from the rate of delivery of the hand pump I would say it's worse than useless for normal running and only any good as a last resort get you home emergency measure! The pump itself I would say is original Winson as like most things they did it is carved out of a solid block! It's a tee shape if I remember correct probably an inch thick slab, milled down in places, about half inch bore and probably about 3/4" stroke. I will have another look another time and see if I have any pictures of it. You don't need a casting to make one though if you want to fit one, you could follow Winsons lead and mill from a solid block or silver solder fabricate. The Winson drawings I have show it bolted to the outside of the tender behind the LH rear wheel (dreadful idea if you want the engine to look reasonable!). I am now building a 6" engine and not bothering with a hand pump at all on that!

The 'tool tray' that sits on the back of the tender is another from solid abomination! No small wonder they went bust when many parts were machined from solid generating more swarf than actual metal left in the finished item! I may have the former I made to produce flanged side plates from 2mm steel sheet lying around somewhere to make the proper prototype tool box, if I can find it you are welcome to borrow it if you want to go the same route, I won't have the press tooling I used to bend the back sheet though, that would have been left in Trinidad where I made it!

Paul.

Paul Gilby.