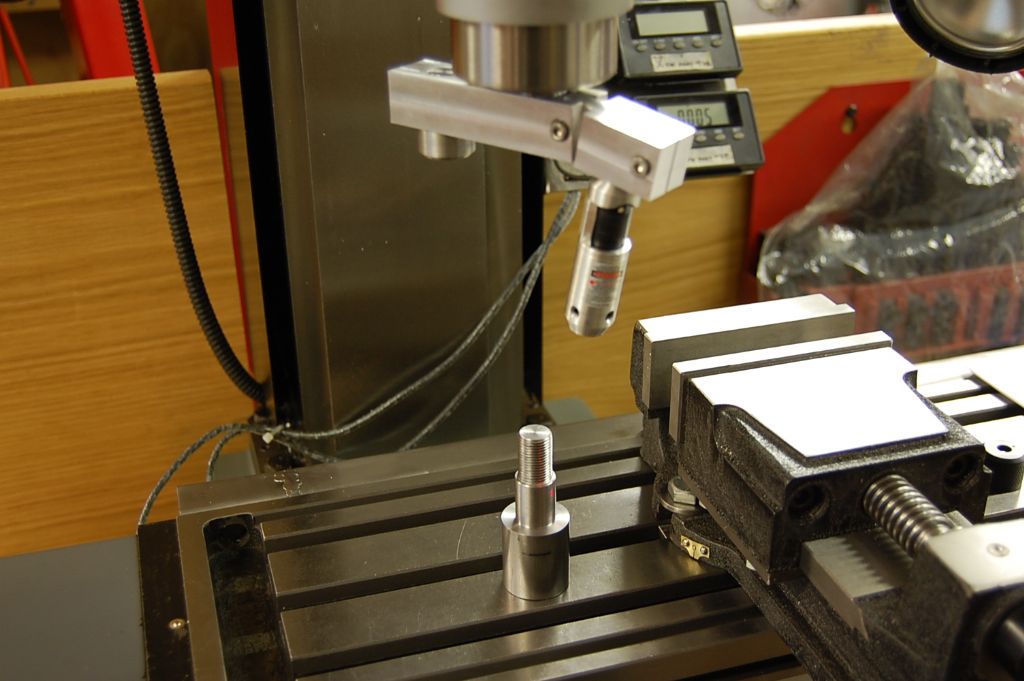

Michael, I thought about the rotary table and a centre (cone) sticking up from the Morse taper, and decided to try it on my newly built kit. A few minutes later I realised all this talk about conical surfaces might be off-target.

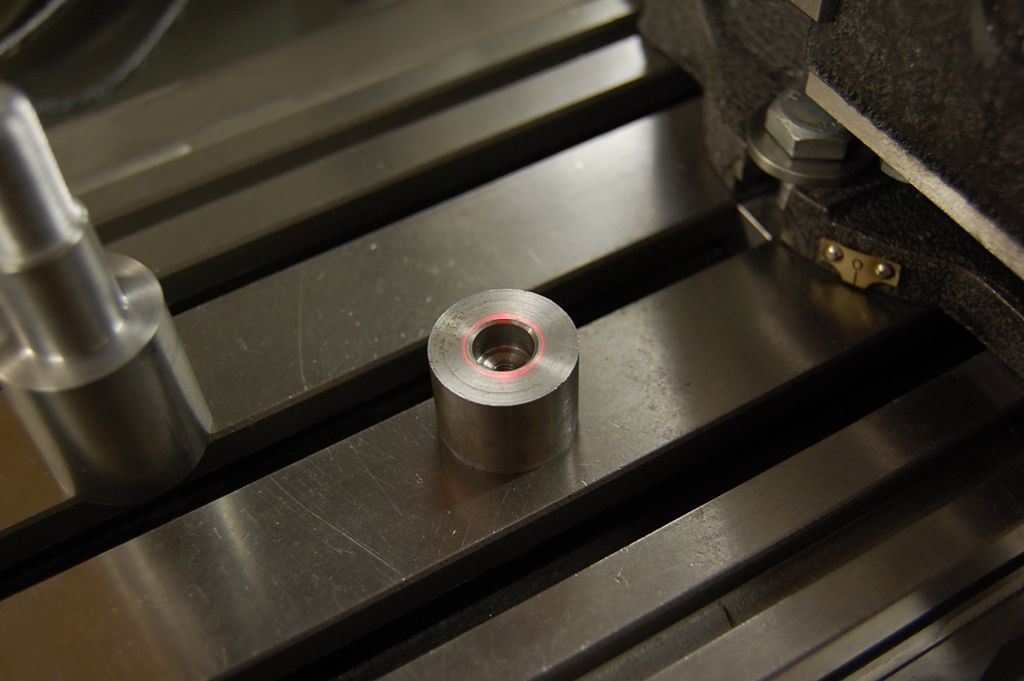

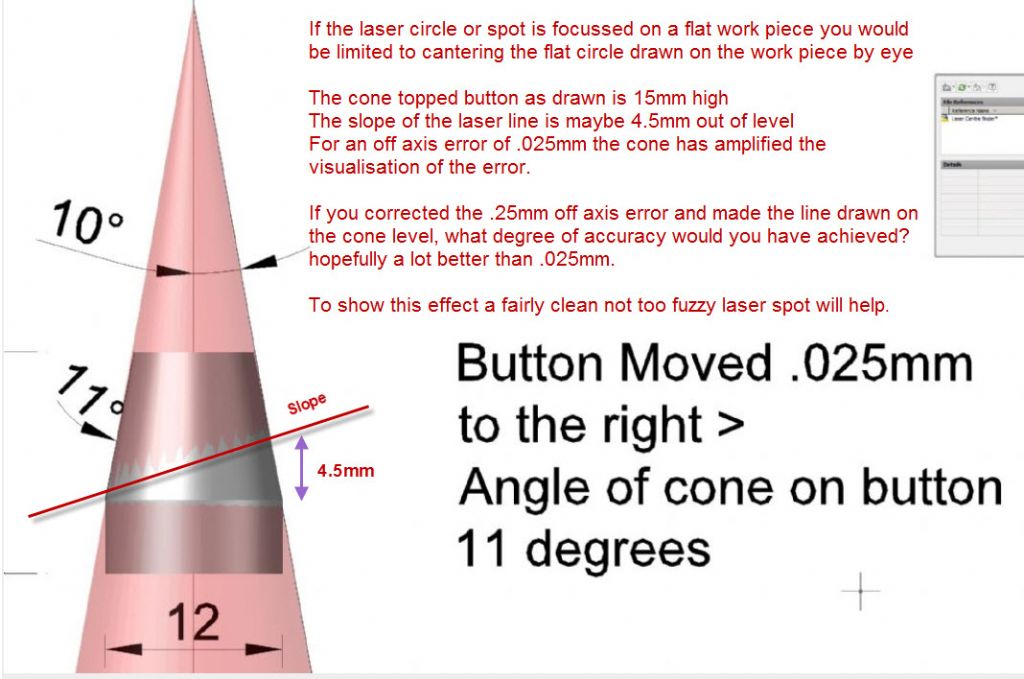

Let's think about how the basic Gelbart idea works. A laser beam at, say, 10 deg strikes the vertical surface of a rod and draws a horizontal circle around that rod if the beam rotation centre is exactly coincident with the centre of axis of the rod. Displace one of the axes and the drawn circle will be distorted (to some sort of ovoid, but not egg shaped, neither is it an ellipse) and no longer horizontal. As you reduce the angle of beam incidence any misalignment of the two axes will amplify the distortion and further tilt the circle. When the incident angle is zero degrees then the sensitivity becomes infinite.

It follows that if you increase the incident angle, for example by making the rod into a cone, then the sensitivity of the rotating laser, in indicating the centre position, is reduced. My thoughts are that this negative effect of a cone applies to the conical buttons theory (sorry John and Michael). I recon that the buttons will however work well if they are conventionally parallel and stick up about 1/4", but are quite wide, perhaps 1/2" diameter or more.

I played with my rotating laser last night and found it more sensitive at 9 deg than at 11 deg, such that finding a datum point better than +- 0.001" in both axes seemed easier. You also need a target of around 1" diameter to properly judge the laser line being horizontal, at this sort of precision

If I'm wrong on the cones I will eat plenty of pie, but I think they exited stage left with a few Dodos.

Regards, Norm.

I am adding this edit to clarify that all the above assumes you are working in the cone area above the laser point of intersection. If you want to work in the conical area below that point, then conical metal targets become useable, but only if the the total target cone angle is greater than the total laser conical angle; ideally around 20 deg more so that the incident angle is around 10 deg.

Edit number two: Hmmm, perhaps I should eat some pie as I now see from his diagrams that John was talking about using the laser cone below its point of incidence; sorry John for trying to kill off the cones. The problem with working in this laser cone area is that the distance from machine head to table starts to get a bit bigger.

Edited By Norman Lorton on 30/01/2014 14:43:05

Edited By Norman Lorton on 30/01/2014 14:51:33

Vic.

Vic.