Posted by Daniel Brannan on 03/07/2023 02:45:41:

Posted by Pete Rimmer on 02/07/2023 21:01:19:

Posted by Daniel Brannan on 02/07/2023 15:04:11:

I never did understand the principle really as surely once the part is in contact with the broach, nothing is ‘wobbling’, all that is happening is one part of the broach is ahead of the others. Obviously it’s clever people than me that came up with this though 🙂

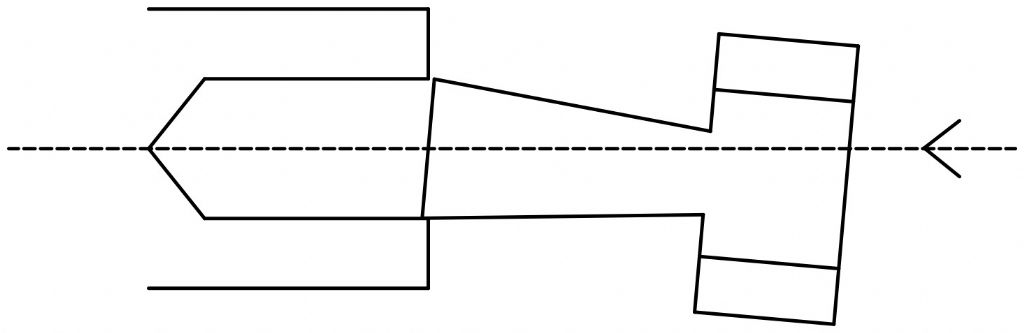

The principle is very simple. If you look at Malcolm's sketch you'll see that the bottom edge of the tool is inside the hole and the top edge is outside. This means that the point at the top will be more to the left when it's made half a turn to get to the bottom. The end of the broach is the cutting face and it plows the metal into the hole as it turns. All you have to do is push it.

I suppose the bit I can’t my head round is how the spinning helps in any way. Plus once you have progressed beyond the opening, surely all of the tool is in contact with the part, just with the leading edge further in

That's correct, it's further in but still doing the same thing, shaving a small amount ahead of itself each rotation.

If it's in the tailstock try moving the tailstock off-set a tiny bit. If you were looking at Malcolm's sketch above move the tailstoks off-set in the downwards direction.

JasonB.

JasonB.