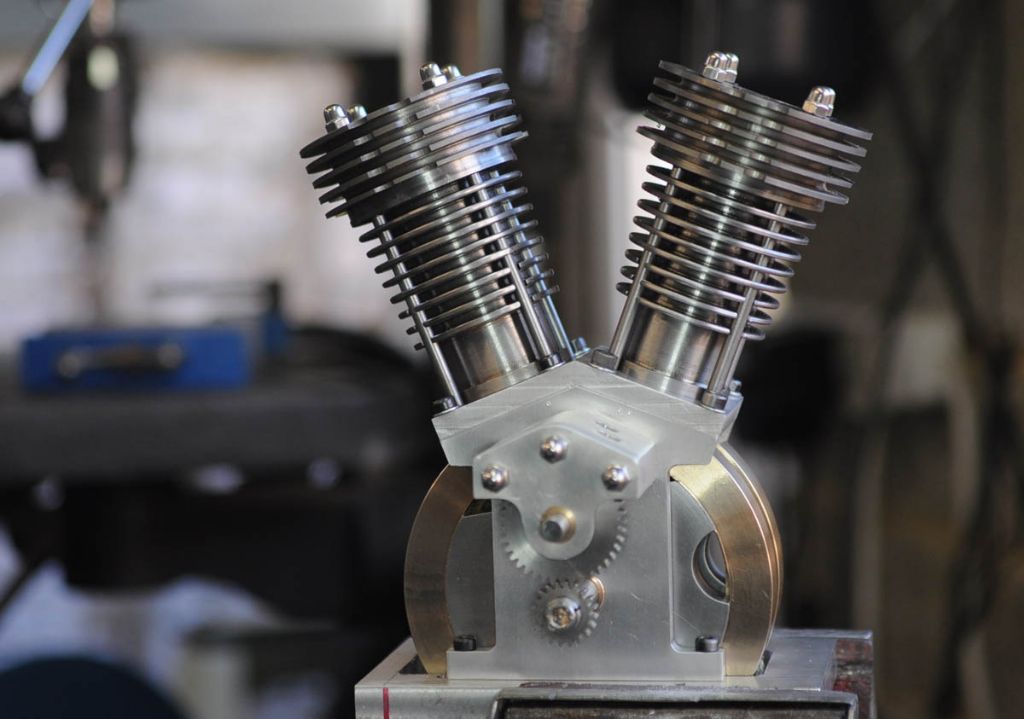

My view of the Hoglet is that it is largely a noise maker. For just getting the engine to run then the cam timings are not at all critical – the article refers to some quite radical changes to get a more Harley like burble. If the cam angles are reversed then it should still be fine, as Andrew may have demonstrated

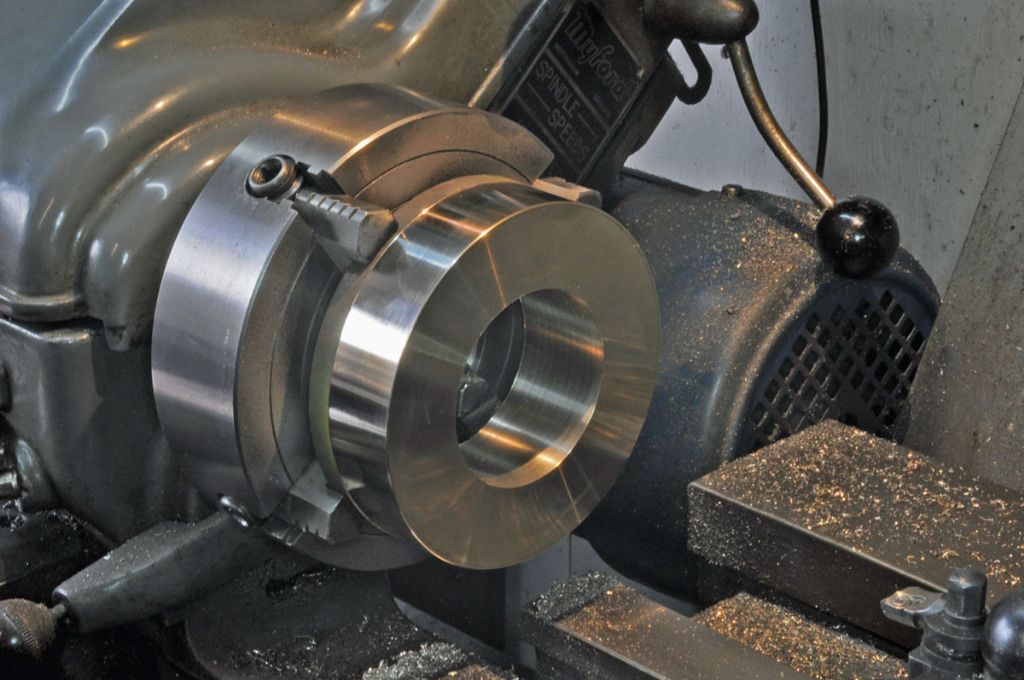

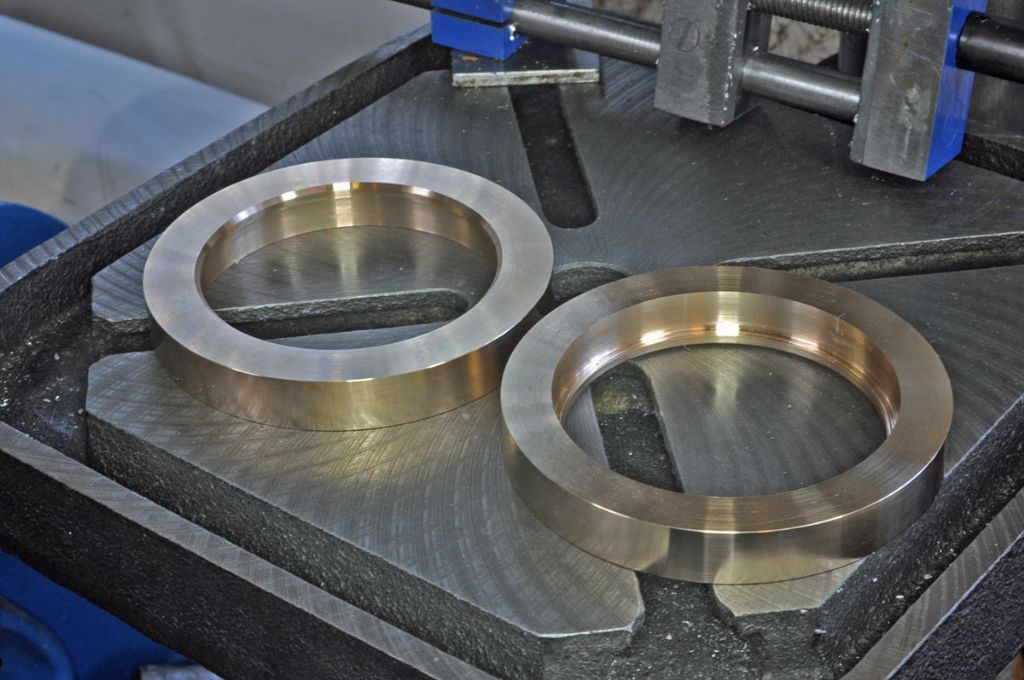

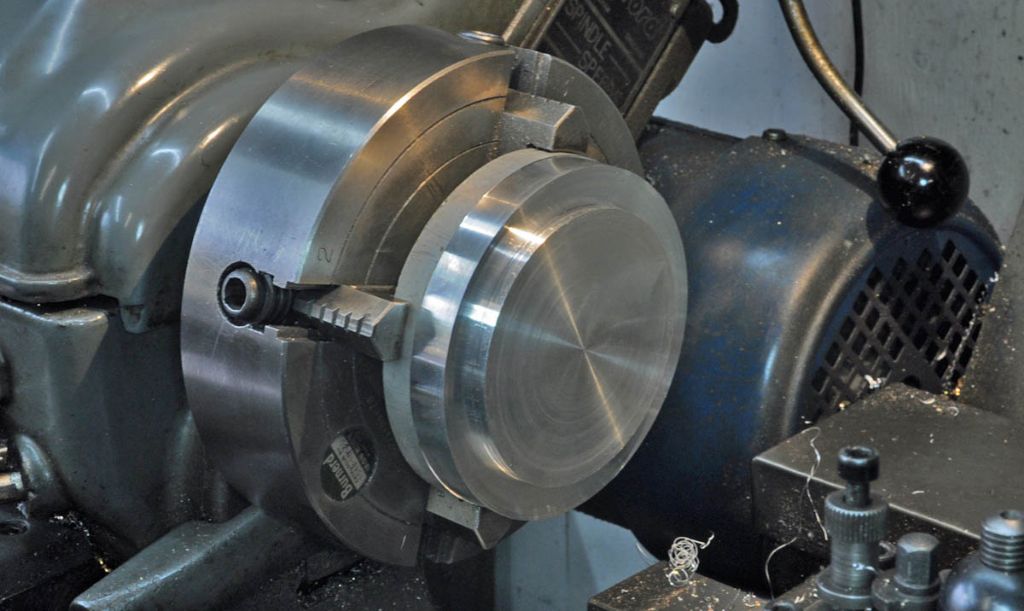

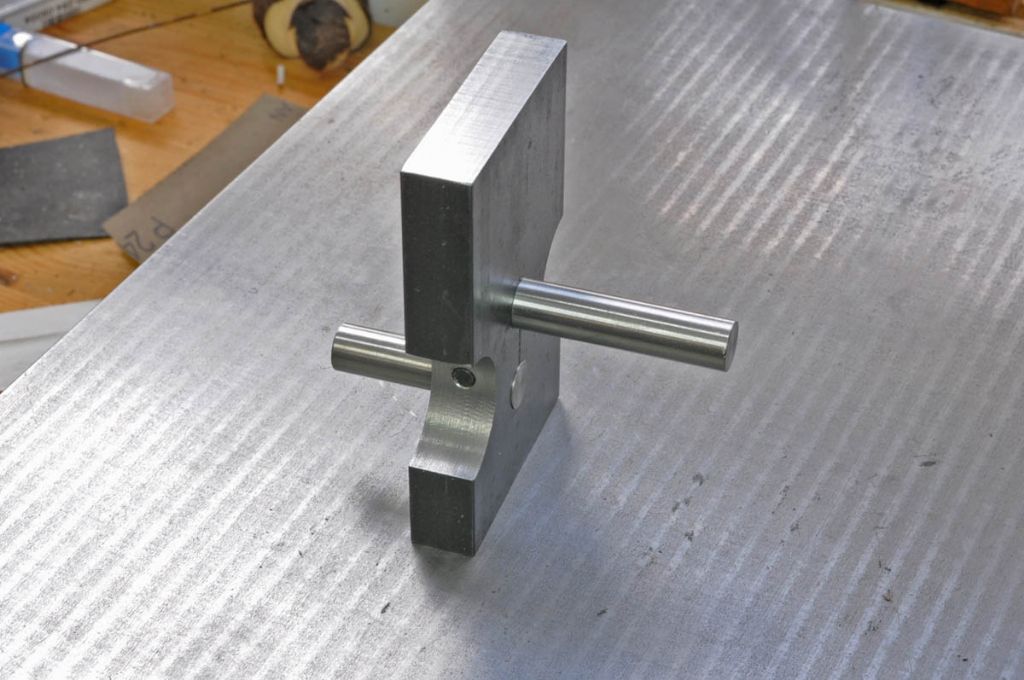

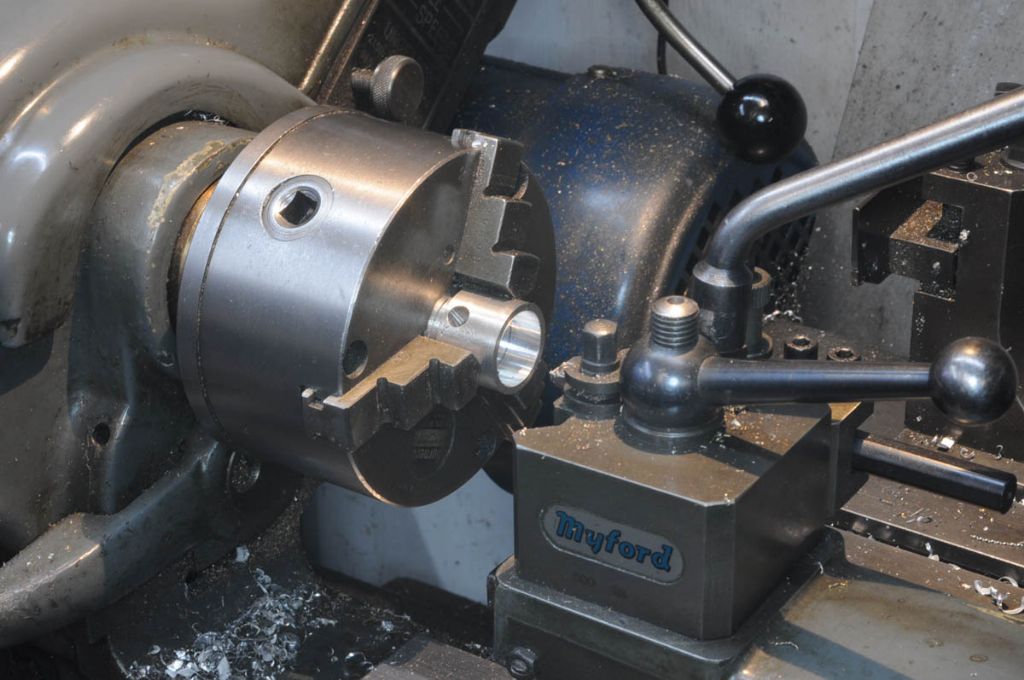

Flywheels. I opted for the expensive bling factor with a length of bronze pipe. Cleaned up inside and out in the 4 jaw. Cuts very nicely with a CCGT 0.4 tip

Tough stuff though, parting in 2 was a struggle. My carbide insert parting blades wouldn't touch it but the HSS blade, freshly sharpened it worked OK, albeit with a lot of screeching and complaining

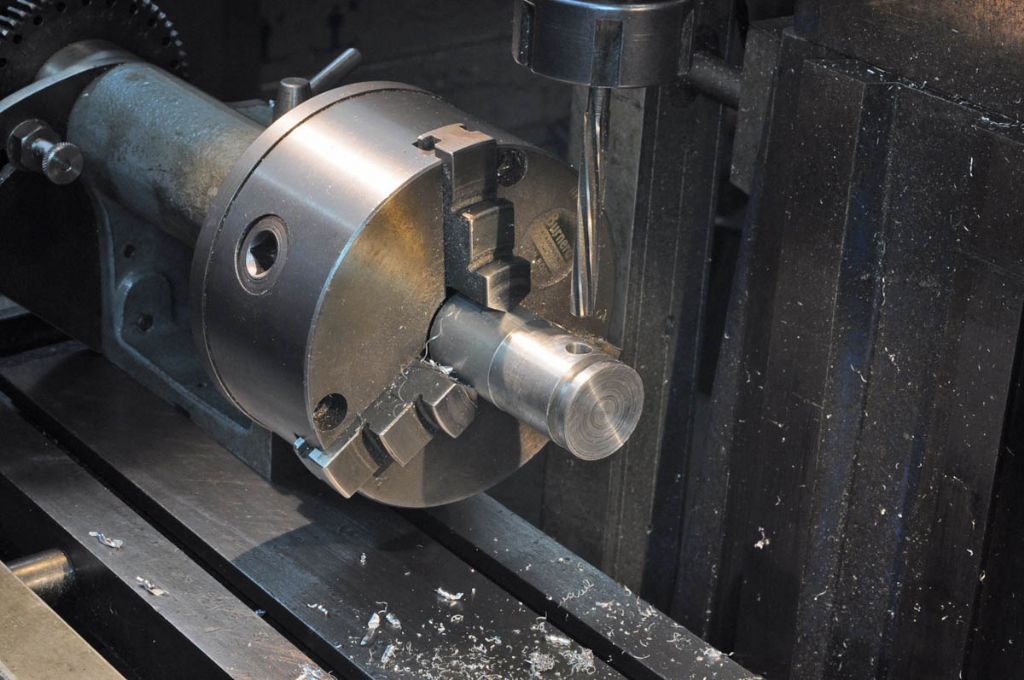

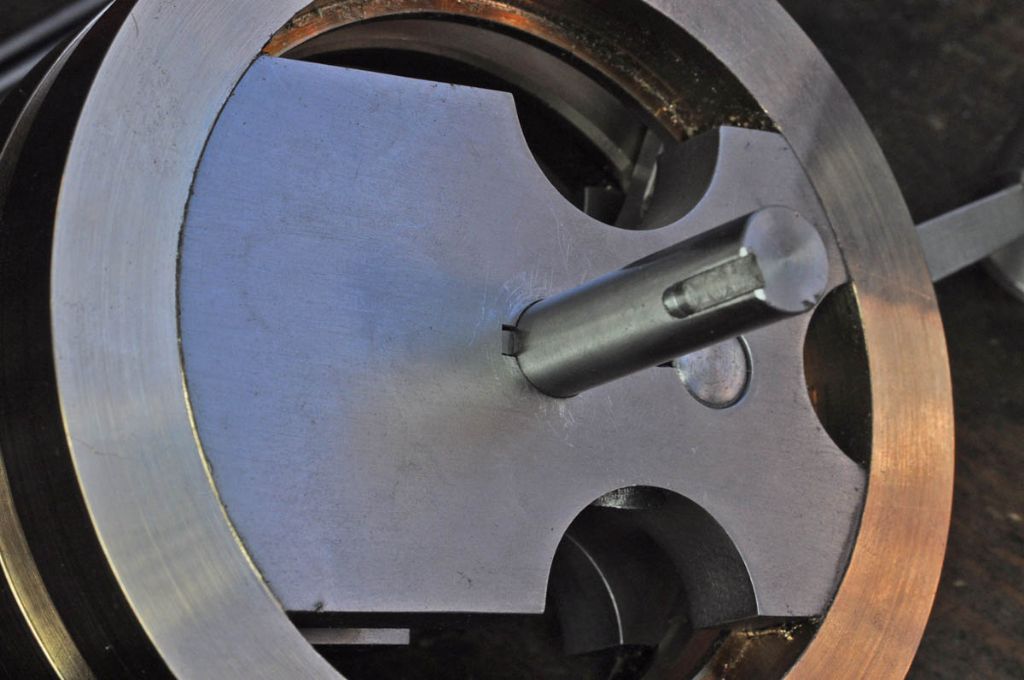

Held in the 3 jaw by the inner circumference for final thicknessing and O.D.

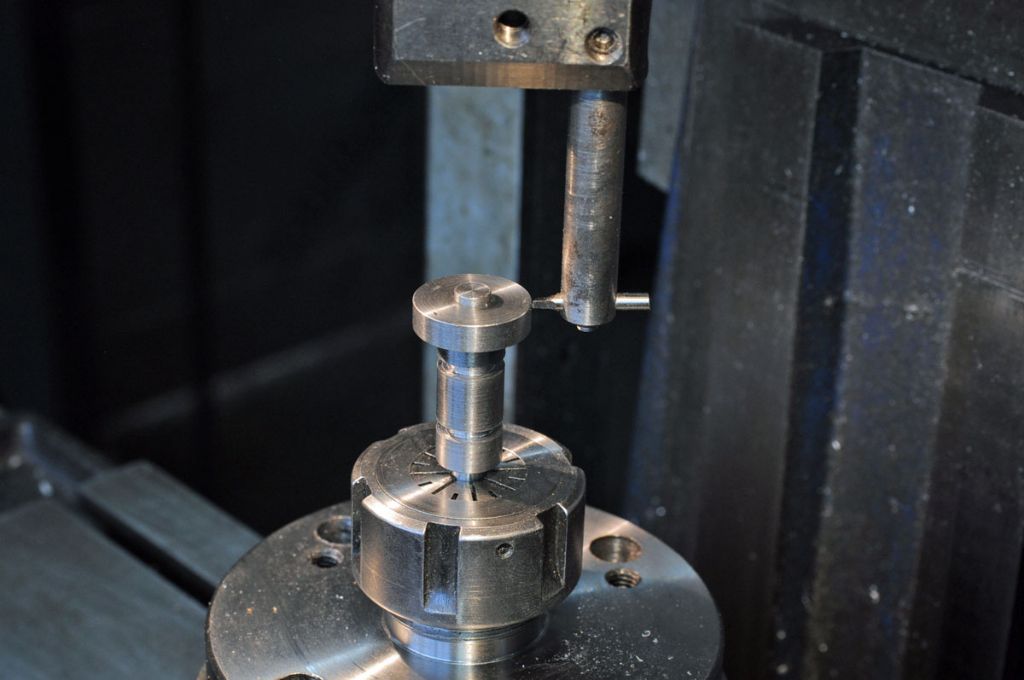

Then transferred to my smaller 4 jaw so that I could bring the inner measurement to size without the jaw interfering with the through cut

Then the chamfer

Shiny!

All that expensive swarf

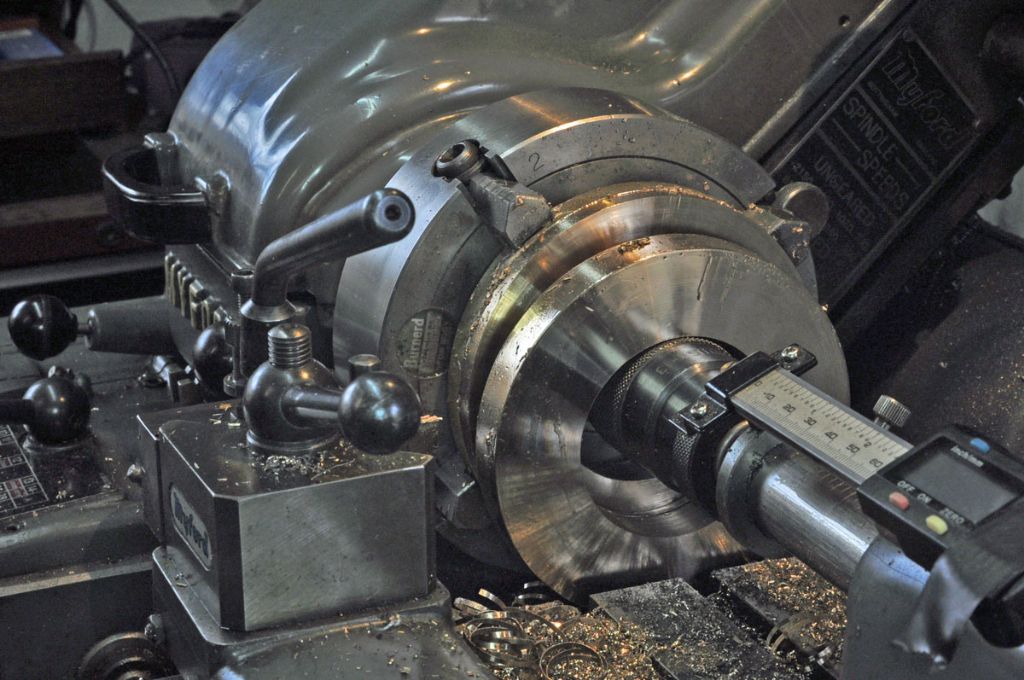

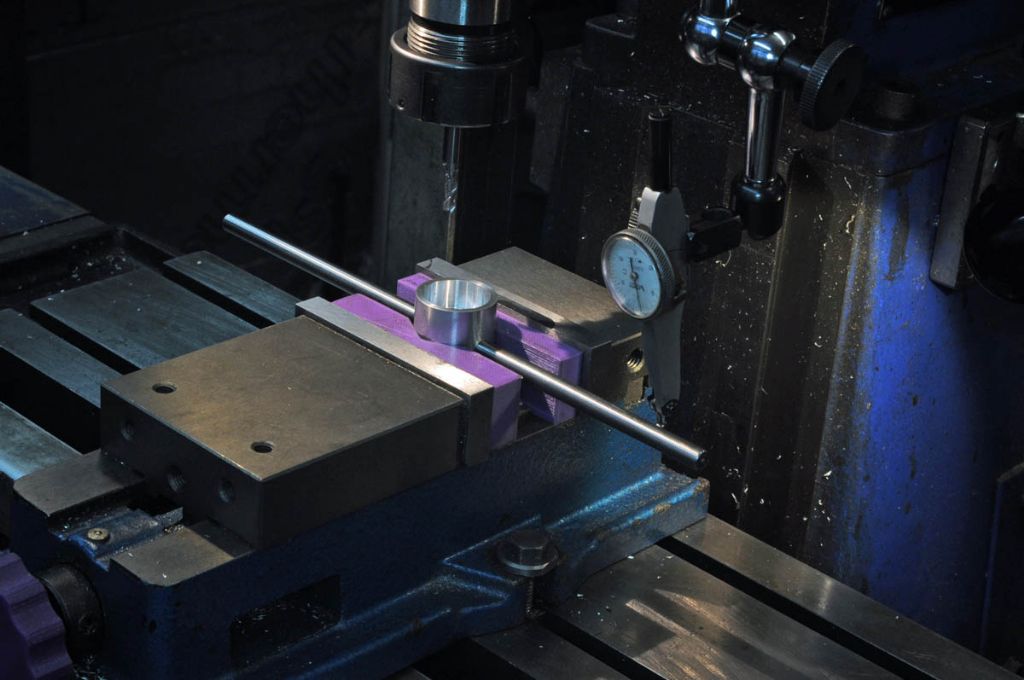

I was struggling to get accurate i.d. by measurement with a caliper gauge – my telescope gauges are not large enough. The crank webs need to be 3 thou over size for the shrink fit. I turned an ally spigot to fit each crank ring that I was more comfortable measuring to get an accurate figure, there is a couple of thou difference between the 2 rings

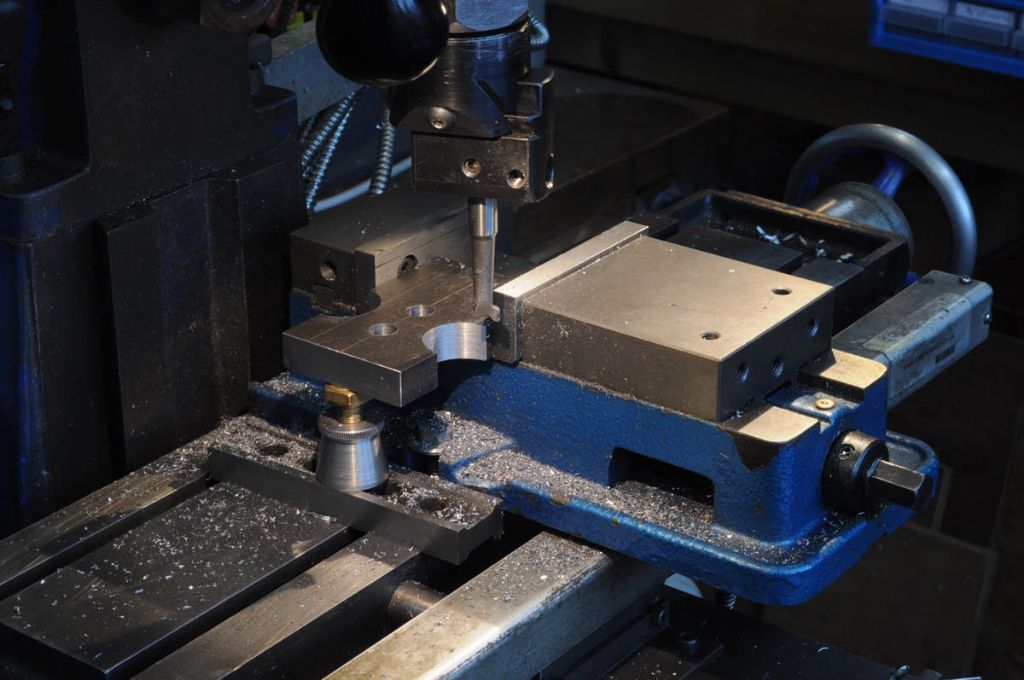

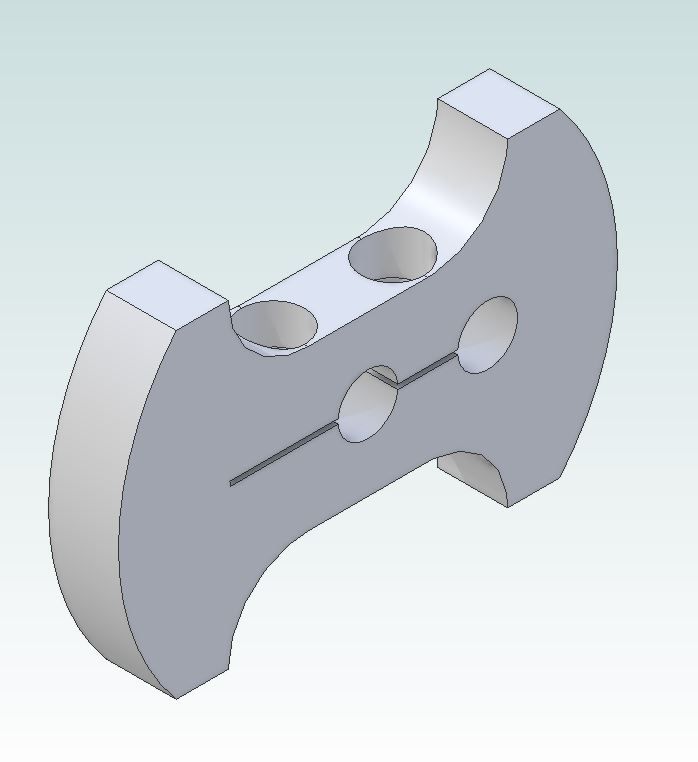

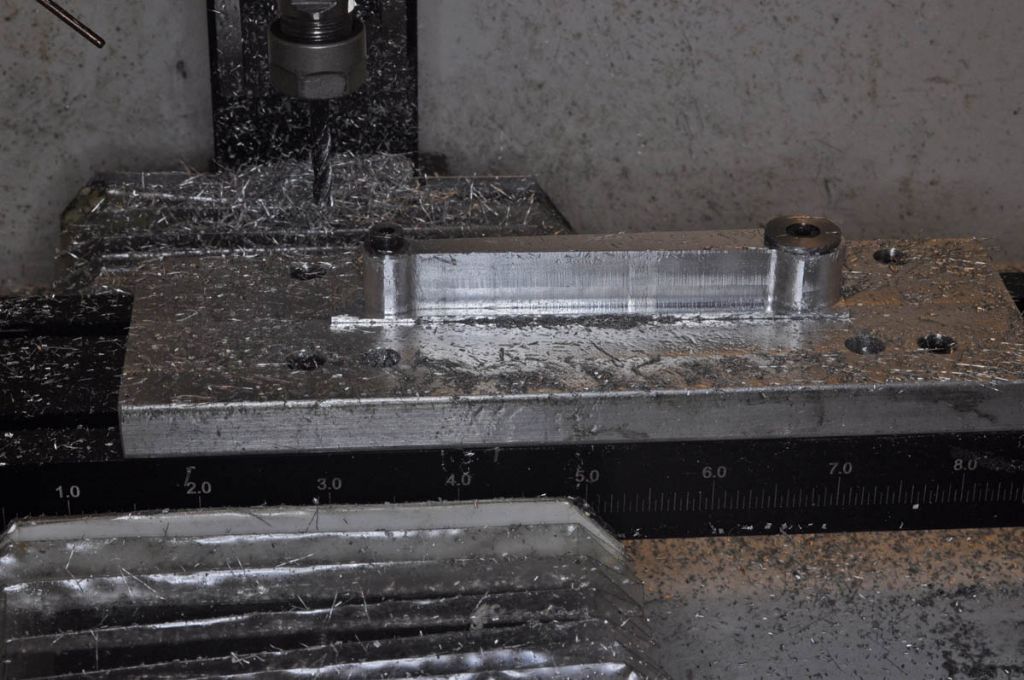

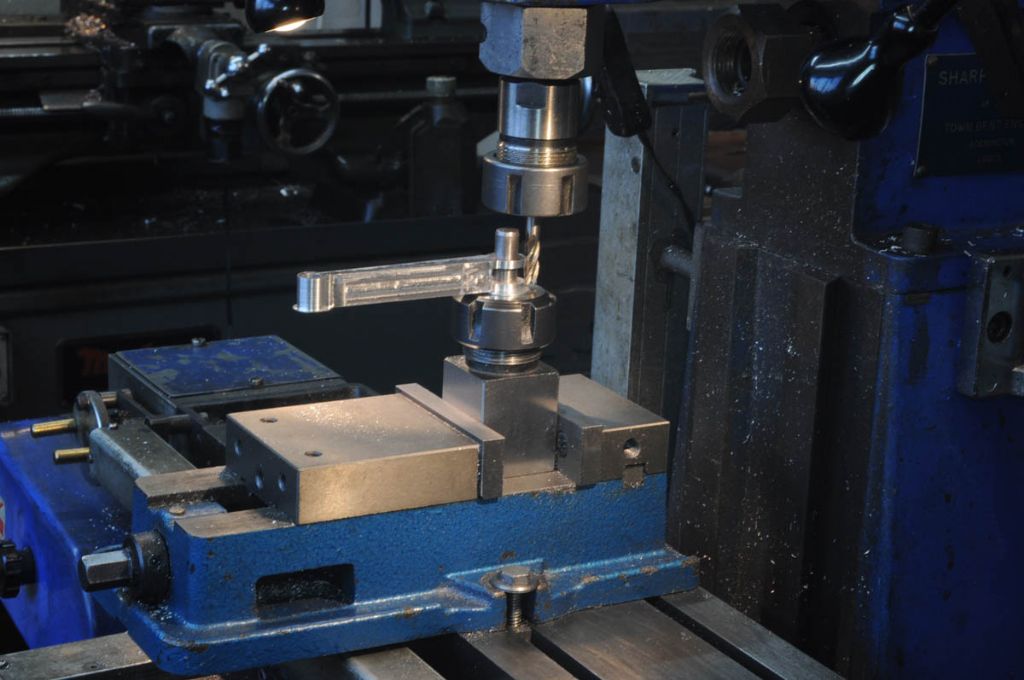

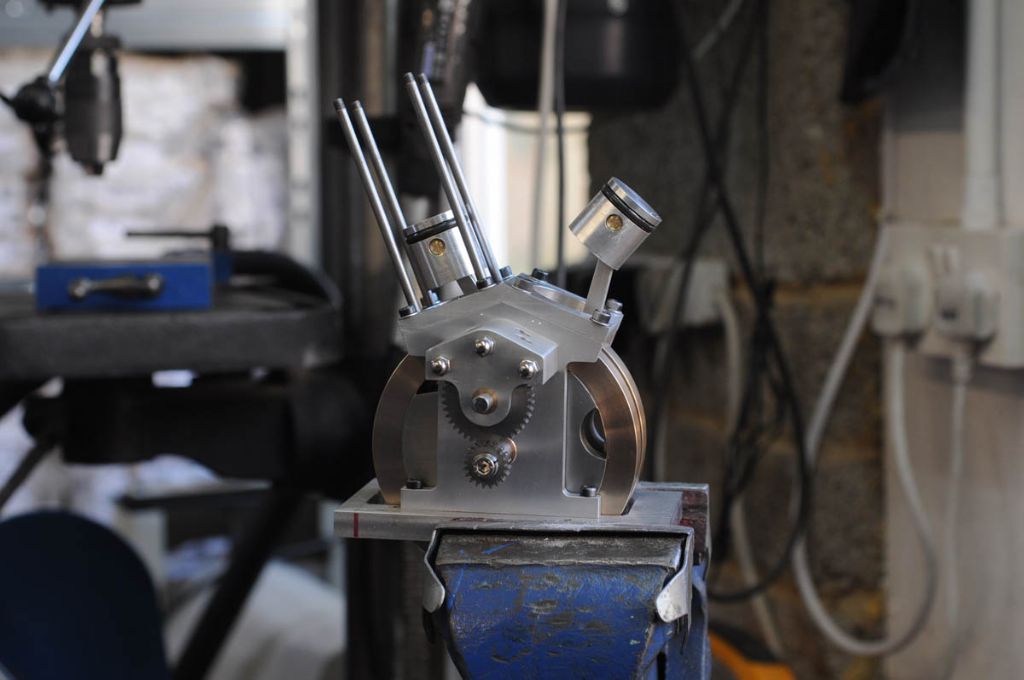

I've been giving some more considered thought to the issue of grabbing the crank shaft and pin in the crank web. My first thought was to minimise distortion by stress relieving the 2" x1/2" bar that I will use so I heated the blanks up to 550C in my little furnace and let them soak for an hour before allowing them to cool in the furnace.

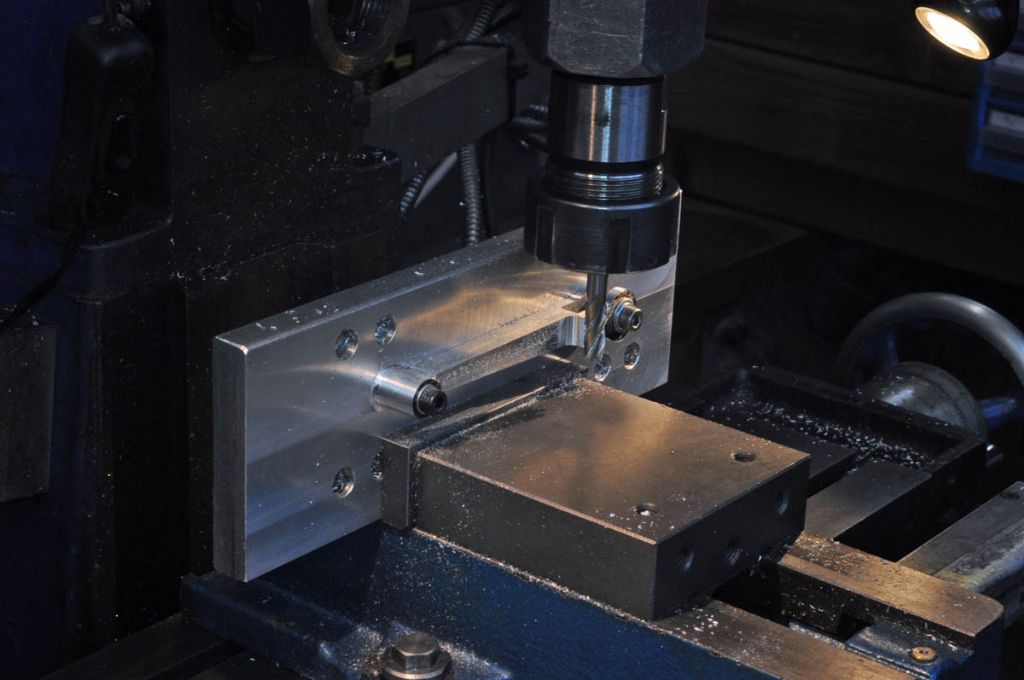

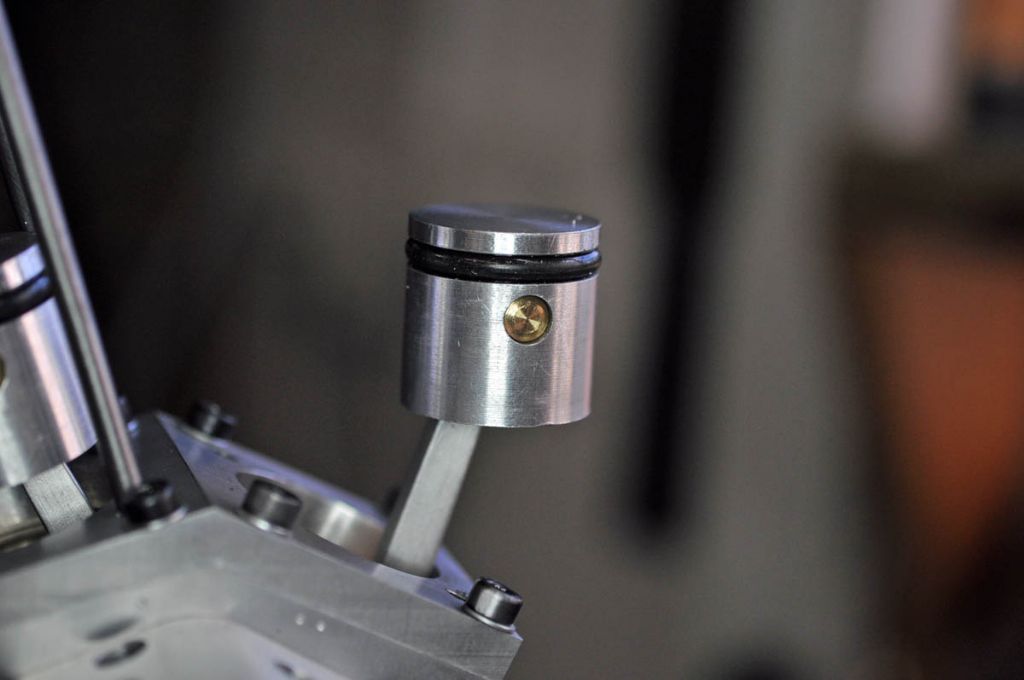

The next idea was that working on the principle that it is easier to make a shaft to fit a hole than vice versa I would ream the hole to 23/64" rather than 3/8" and turn down the end of the pin for a good, tight fit. The disadvantage of this method is that the crankshaft/con rod assembly will have to be pre-assembled and the crankcase built around it

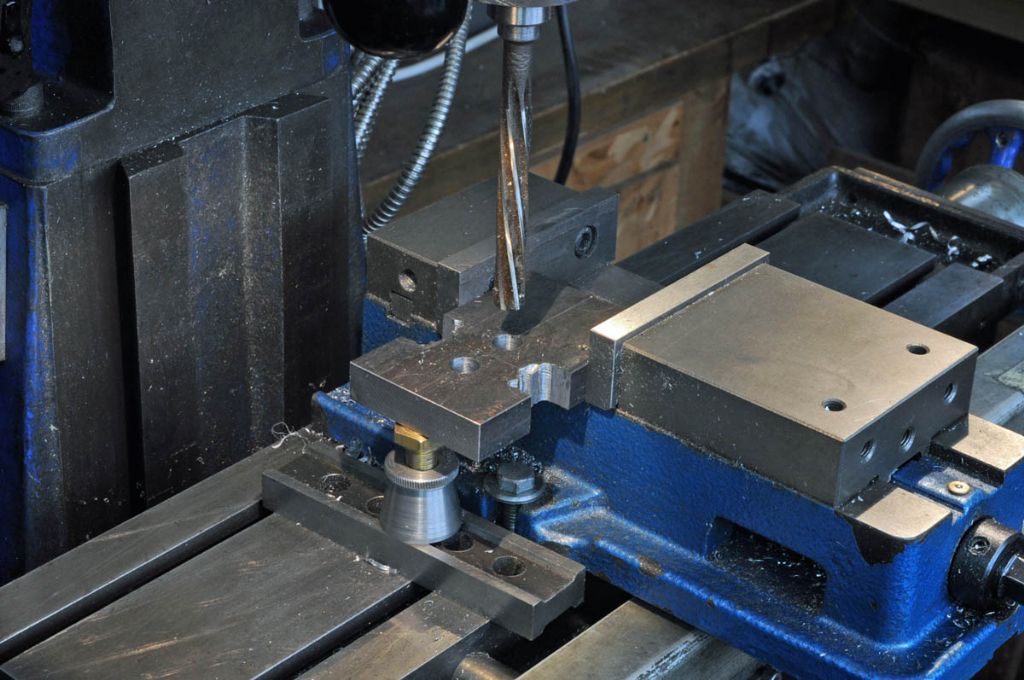

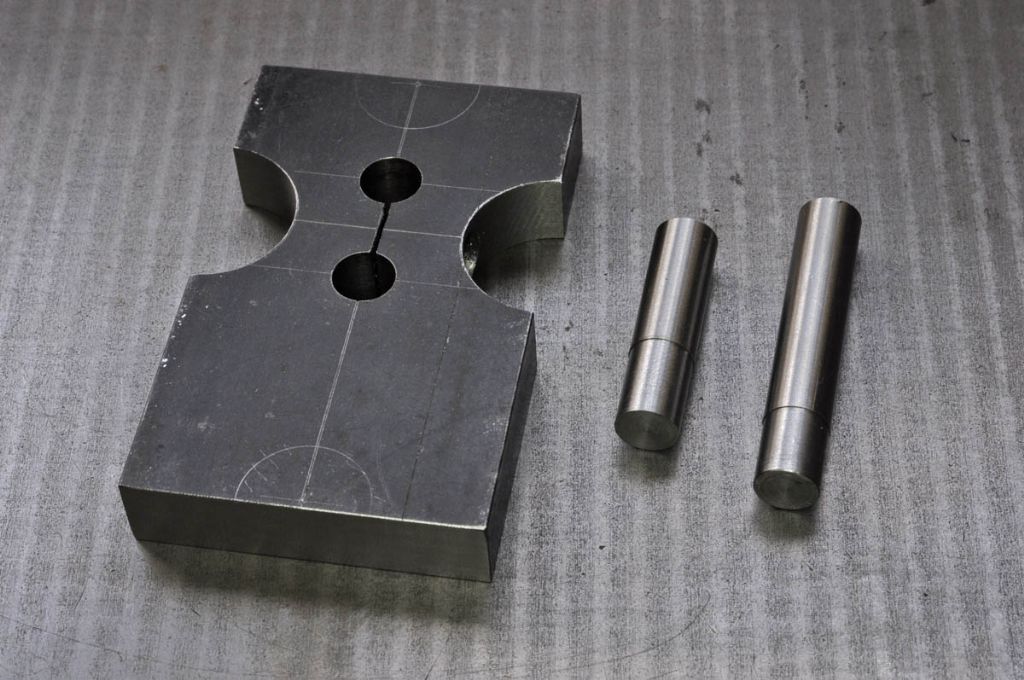

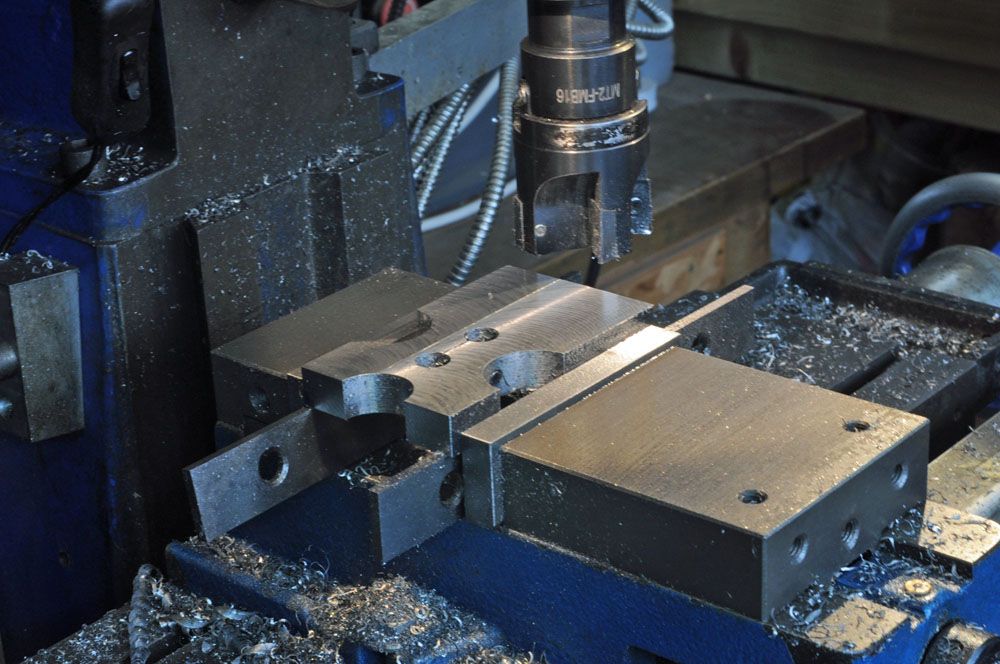

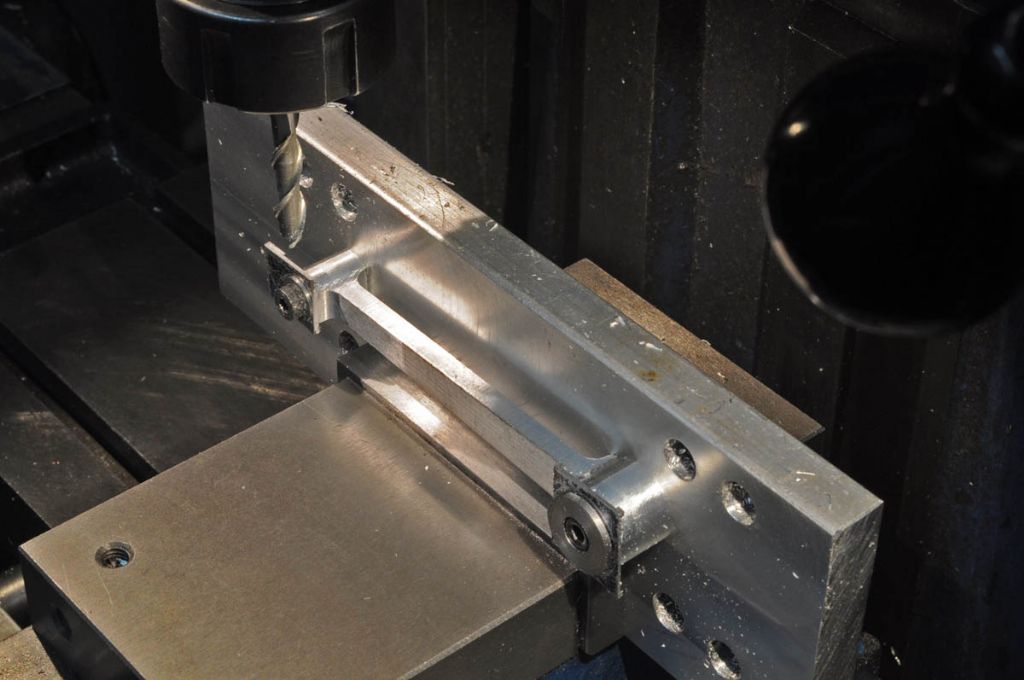

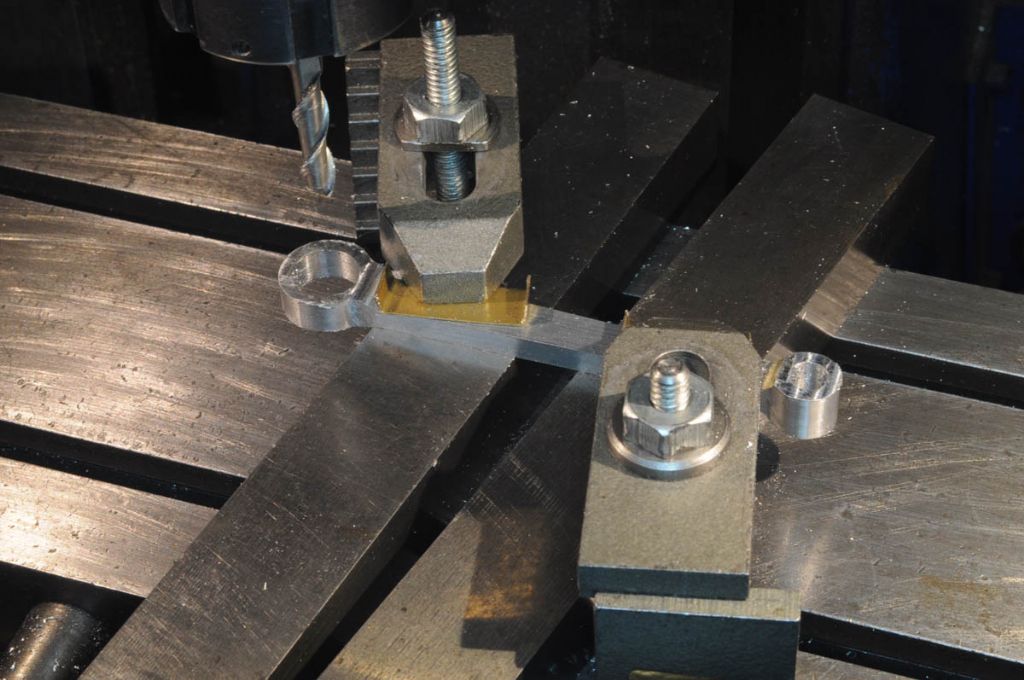

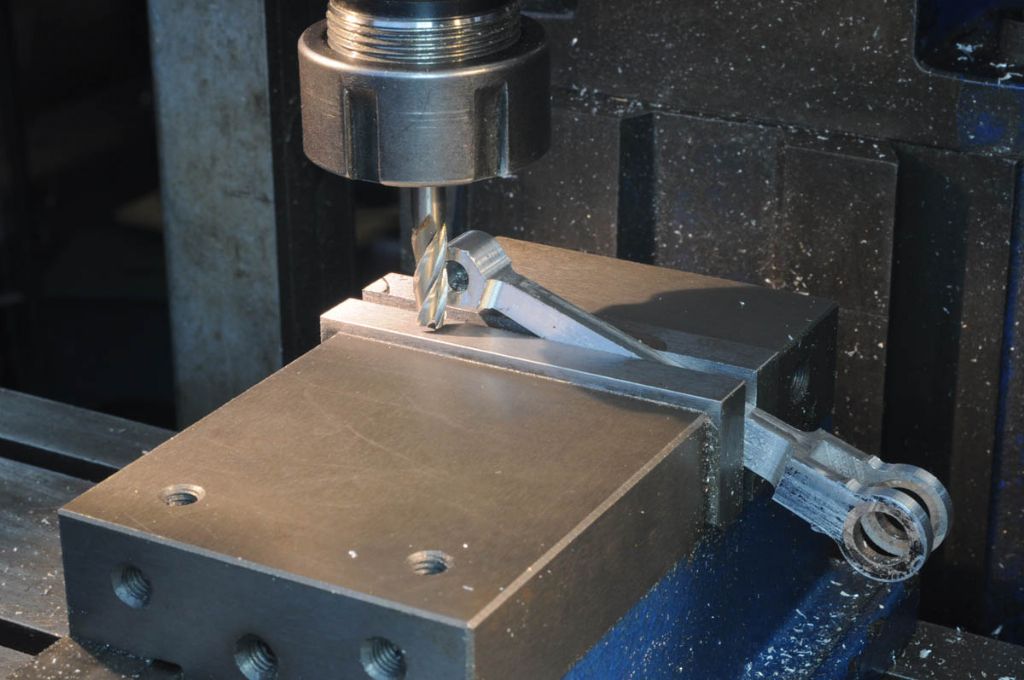

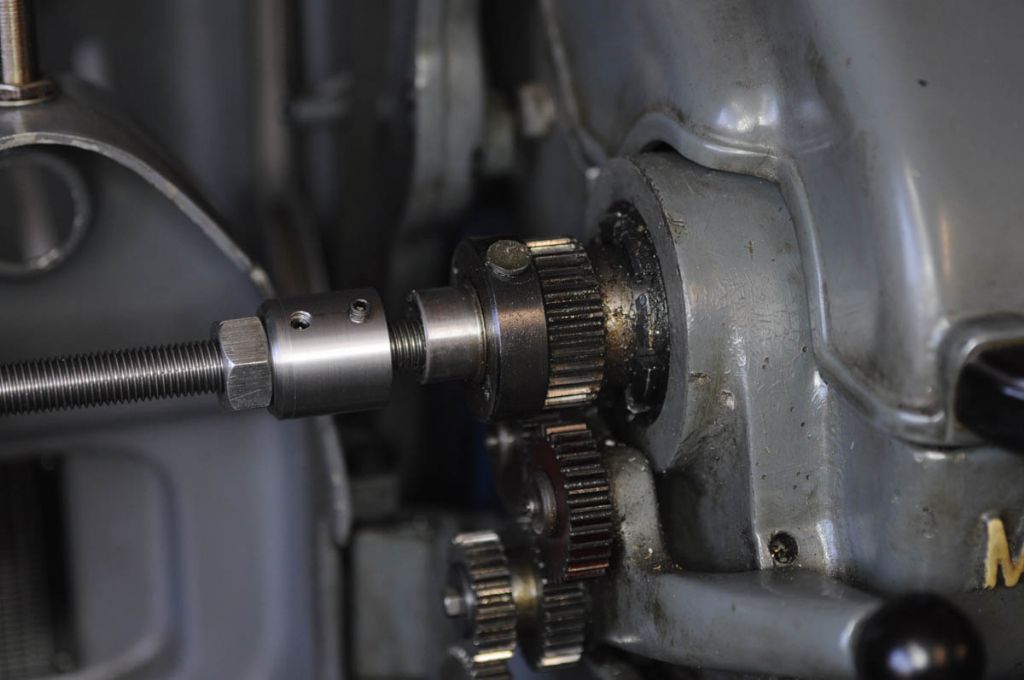

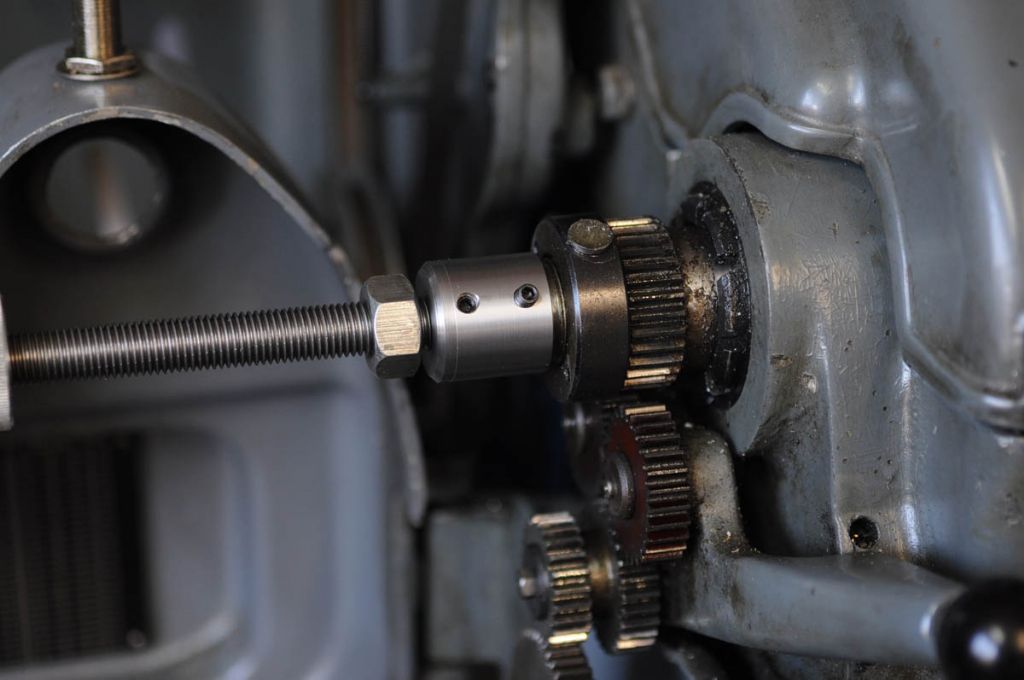

The weight relieving crescents were roughed out by chain drilling before finishing with the boring head

Quite a bit of trial and error ensued. To cut a long story short the the reamer (of unknown provenance and tolerance) is nominally 0.359" diameter. To get a pin to grip in the hole using an M5 screw to close up the holes the pins needed to be a tightish "tap home with a hammer" fit 0.362" diameter and be within 0.0002" the same diameter otherwise one would tighten and the other wouldn't. That entailed quite a bit of work with a dead smooth file

Both of these pins held securely enough such that if I grip them tightly with the fibre jaws in the vice the pins will turn in the vice rather than in the web

So I guess that sort of works and will have to be repeated for the other web. Whether that is better than using Loctite I'm not sure. However, the experience leads me to wonder whether an undersize 3/8" reamer might do the job. Not easy to source for a reasonable sum but a 9.5mm H7 reamer is nominally 1 thou under 0.375" and ARC sell them for a pension friendly(ish) sum. Order placed…

Watch this space for the next exciting installment,

Rod

GrahamS.