Thanks for the contributions on the saddle. In the end, I looked at my saddle casting and decided to place it in the useful scrap bin. I then took a gamble and simply bought another from Kennions and this really nice casting came through.

All 4 sides are remarkably flat, straight, square and right on size!! Well worth the money. Just a small amount of work with a file and it will be done.

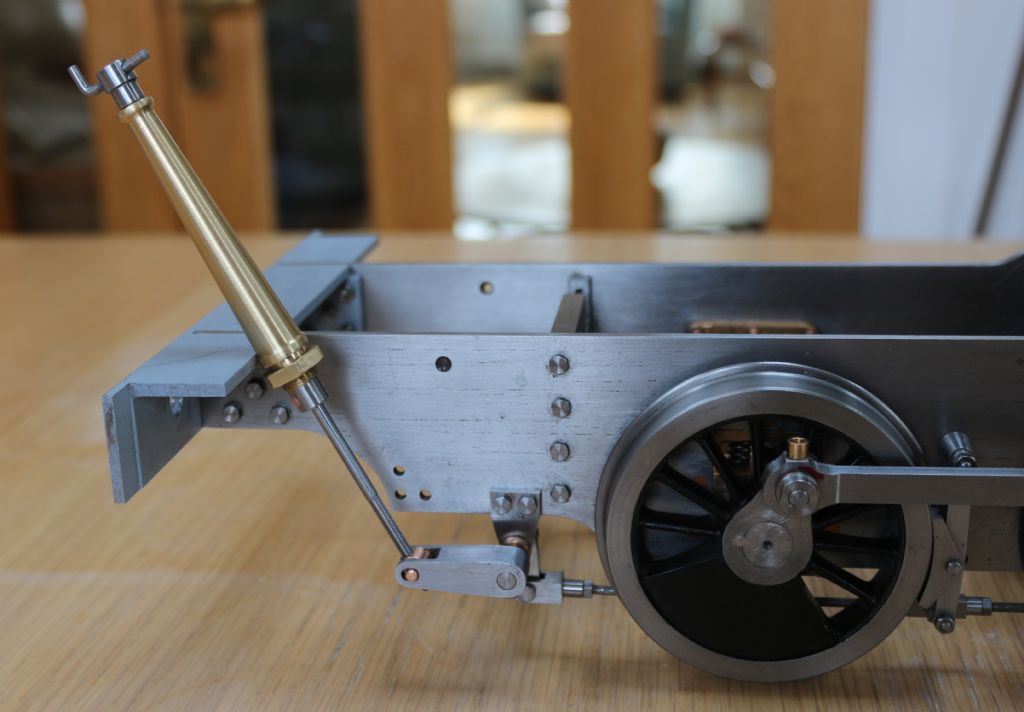

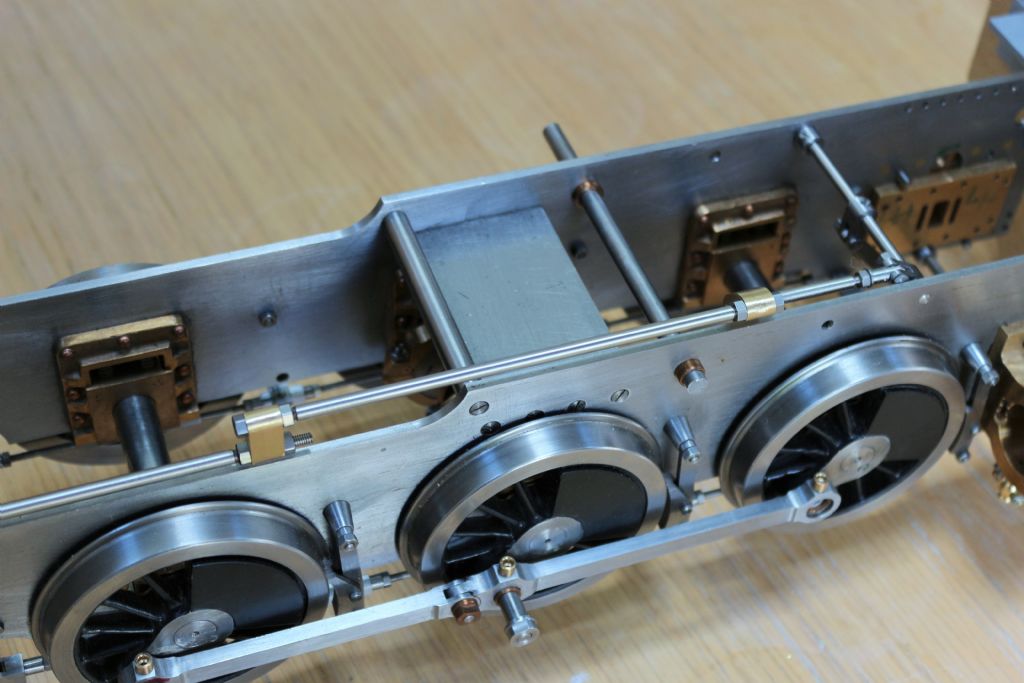

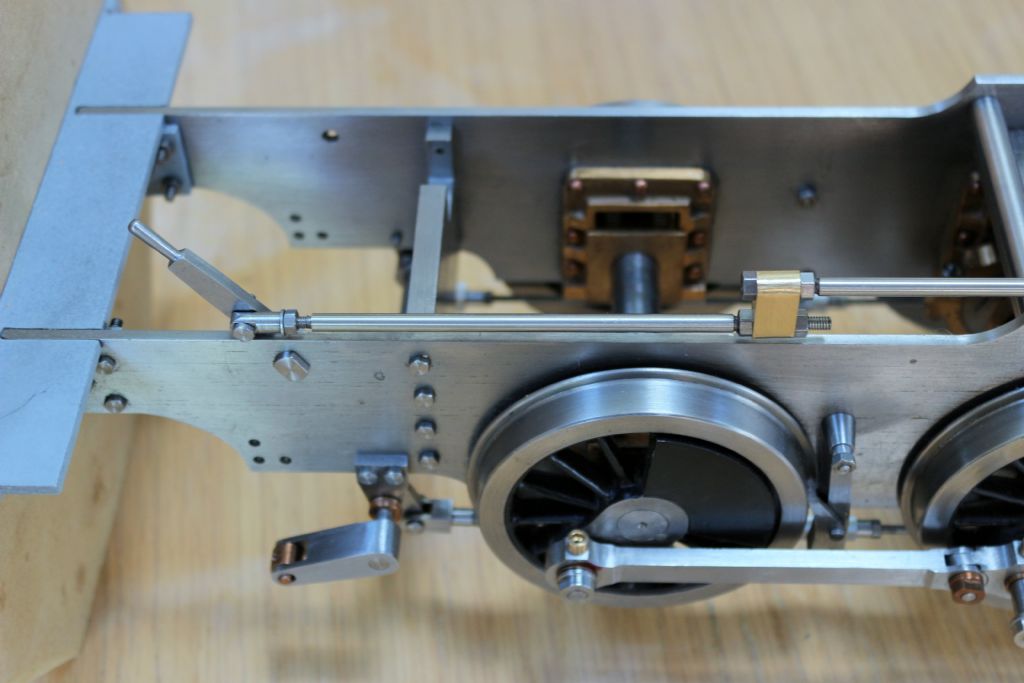

Being honest, the saddle has been a diversion from making all those nasty fiddly bits for the cylinder drain cocks, valve gear and brake gear. I really did get bogged down with them and found it difficult to get motivated and move on.

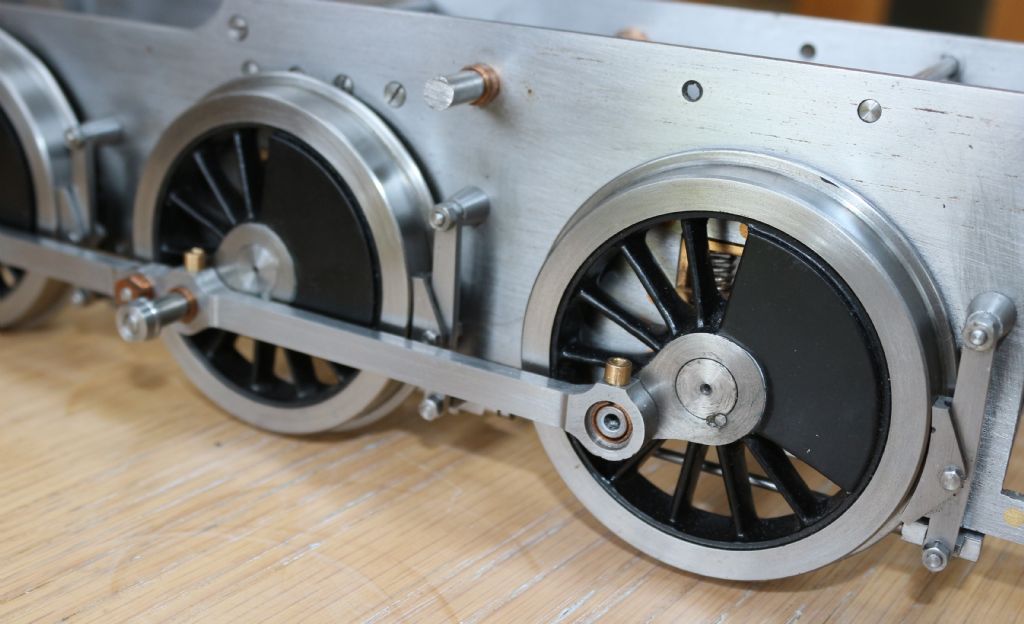

Anyway, the brakes are now fitted and they work! The leading hangars appear to miss the cylinder covers but some slight mod might be needed when the cover fixings are added.

These shots also act as a reminder to paint the wheel hubs at some point. I hate the look of the wheel pins.

Phil H1.