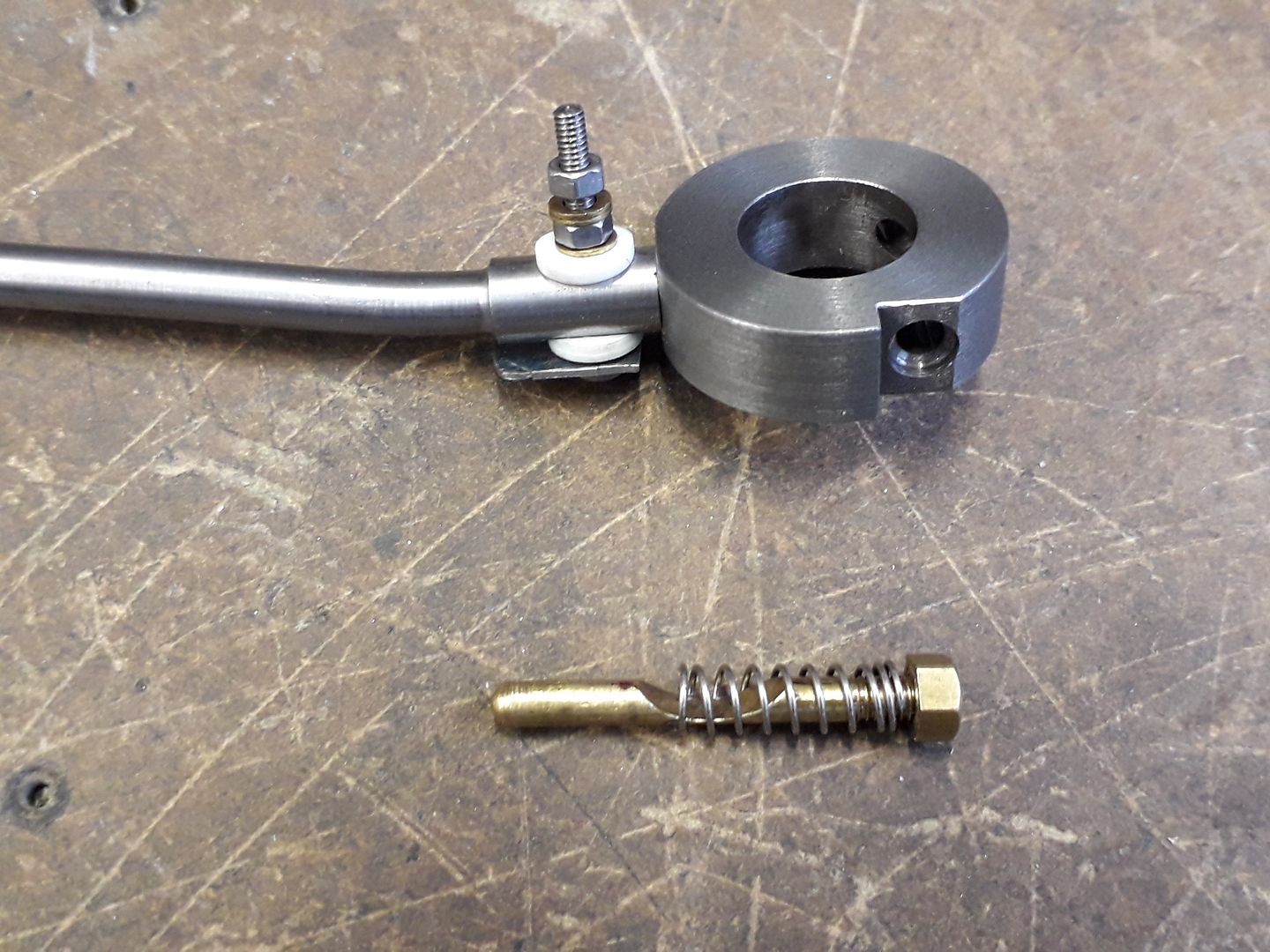

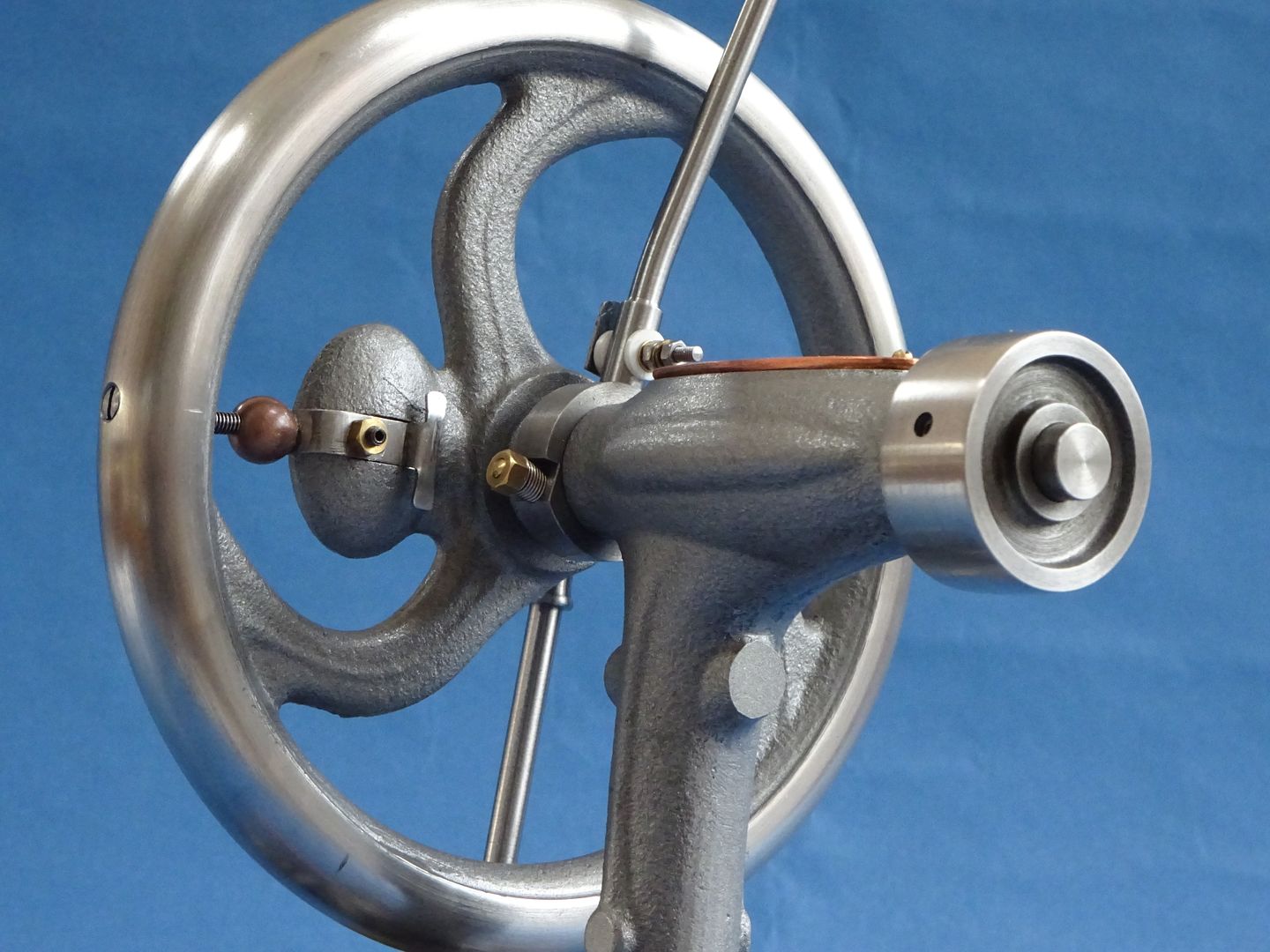

I did not take many photos of the adjustable timing bracket. Below is the lever having had a 2BA thread put on the end it was slid out of the chuck to reduce most of it's length to 3/16" leaving a 1/4" collar for the contact.

After cutting off it was held the other way round and a decorative ball turned on the end. The collar is straight forward turning and milling and the brass cotter applies the friction to hold it in position but still allow easy movement to advance and retard the timing. I opted to use Corian as the insulators rather than the suggested materials.

The "hemi" cylinder head was turned from some cast iron and as I don't have the large diameter ball nose cutter suggested I first drilled to depth and then hand cut the shape.

It was then held the other face out in the soft jaws and the outer curve also shaped by hand turning with a flat ended tool.

Finally over to the mill to drill for the fixings

The fairly long piston can be turned from the chucking spigot that was cut off of the base casting but I chose to use some 25mm CI bar. After turning and cutting the groove for the quad ring it was held in a collet block to have assorted holes and notches cut which provide the porting for the Loyal cycle.

The engine is designed to run on a surface vapour fuel tank which is based on a 1/2 pint "Ball" jar, to increase the surface area a felt wick is fixed to the lid and sits down in the fuel. This is held together with a central screw that is drilled for the vapour and has a reduced diameter end for a fuel pipe, here the head of the screw is being slotted.

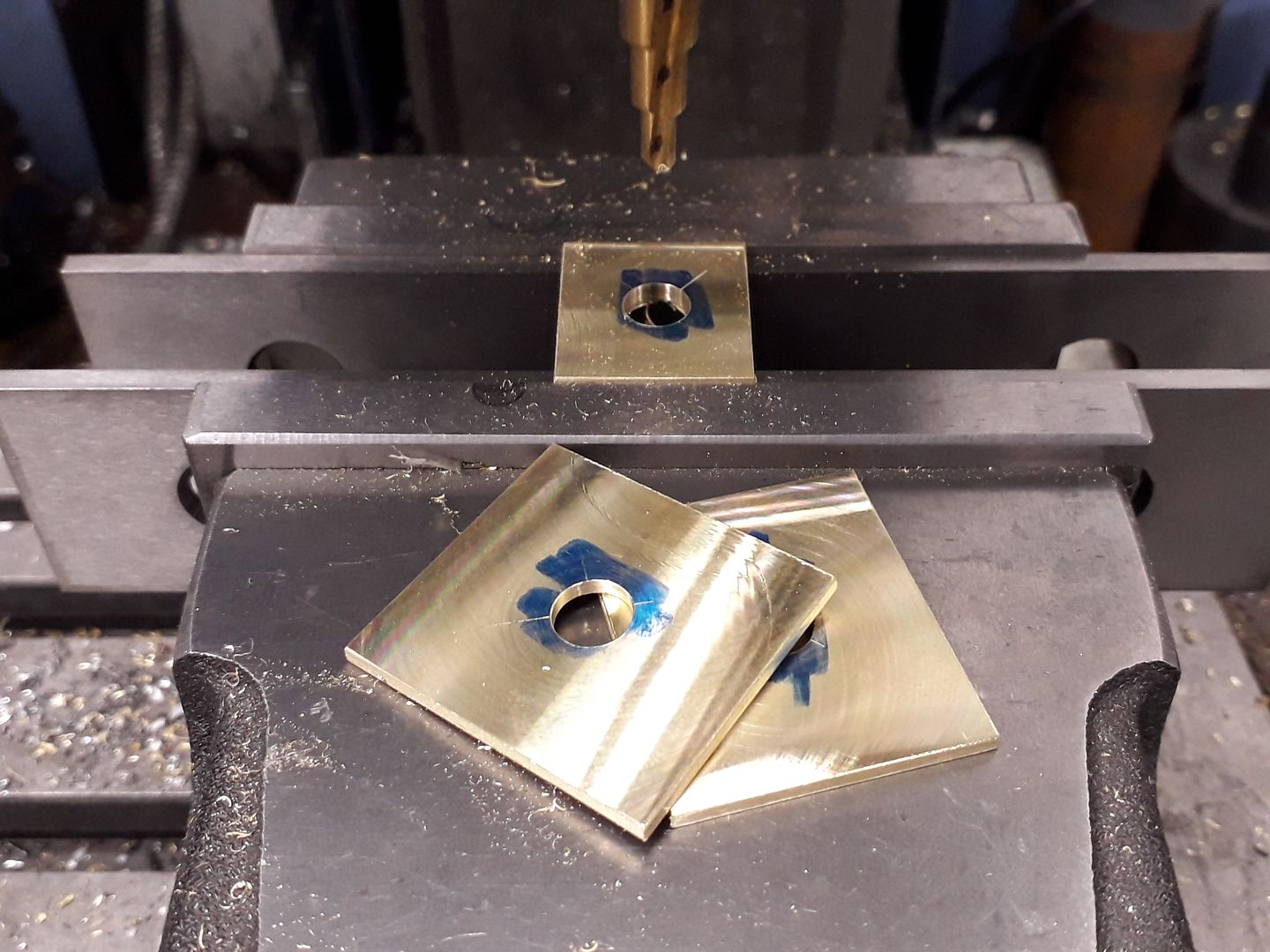

Some large brass washers are also needed, rather than slicing up good bar stock I had some old 1/8" brass door kick plates that were cut up and milled to thickness followed by drilling the central holes, a step drill saves the risk of a jobber drill snatching in the brass.

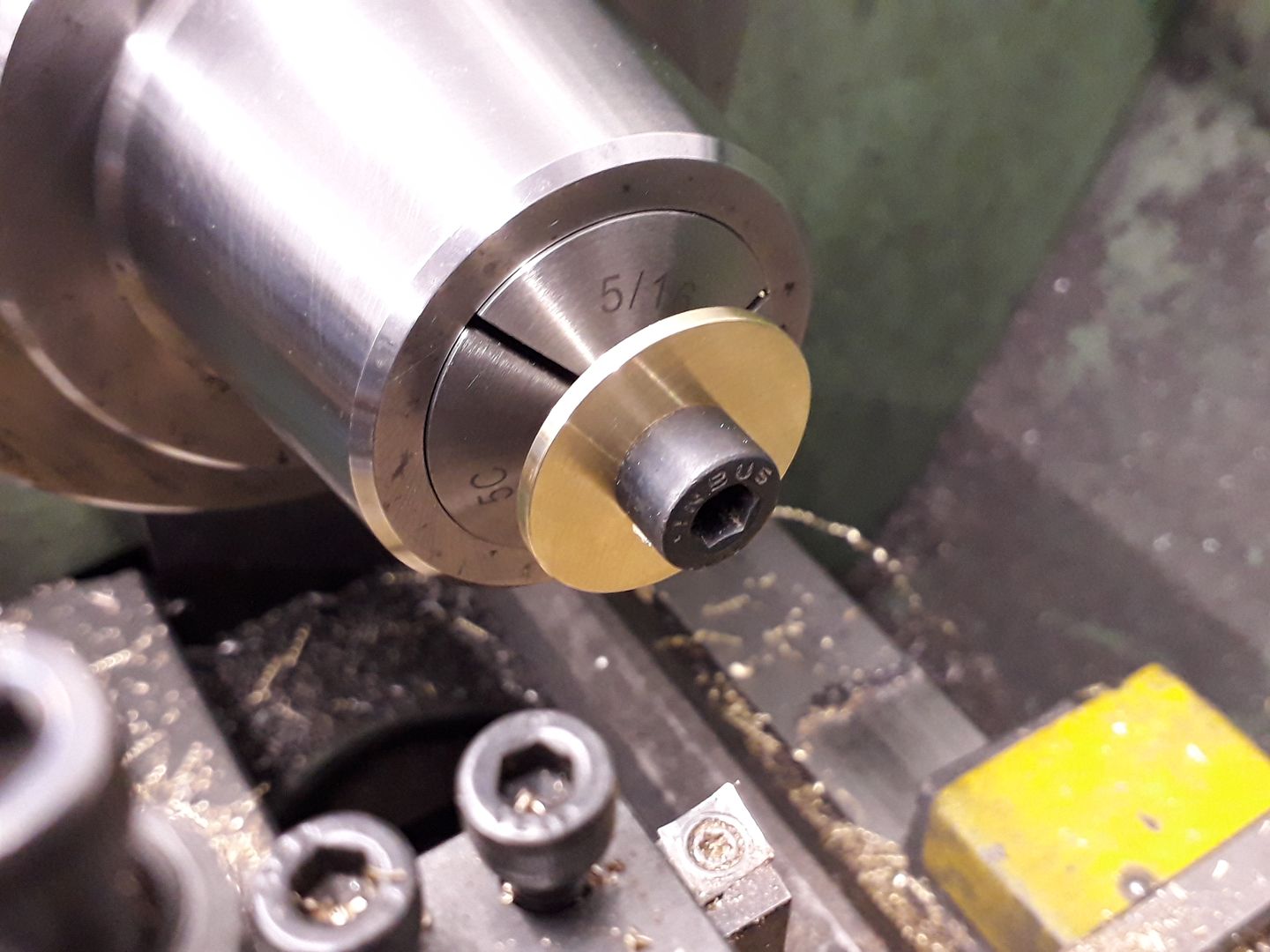

They were then rounded off in the lathe.

This is the finished vapour tank

And the inside showing the felt wick

Final finishing touches are a pulley to go on the other end of the crankshaft turned from the chucking piece

And the nicely etched nameplate. This also has two recessed pockets in it to hold oil and holes are drilled through this, the bearing housing and bearings to get the oil down to where it is needed.

Claudio Masetto.