Hi Terry,

I’m probably a bit late for you to get his before work but I would get a 9X4 prop if you are able. The engine will turn this with ease and the low pitch will allow the engine to rev freely without loading – ‘rev’ means run smoothly not ‘top screaming whack!’. Your nylon prop has probably suffered with light degradation over the years. A blessing in a way – had it gone whilst running ????????

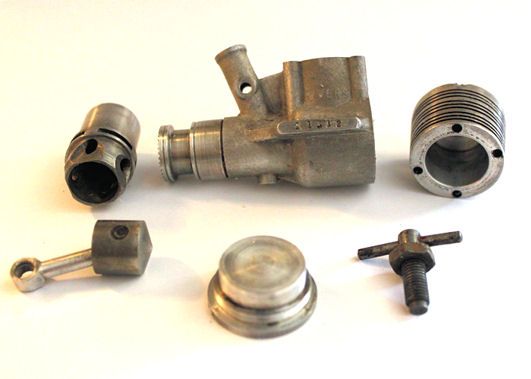

Jens advice on establishing the starting position may prove problematic if the contra piston is very tight in the bore. Screwing right down over compresses the engine and it could (not will) lead to damage to the con rod. Personally I would think that your problem at this stage with such a short time to get it going is down to lack of good ‘flicking’ practice. Rivers engines have/had a good reputation for ease of starting so I think it unlikely theres a lot wrong there.

If you are right handed set the prop at about ‘ten past eight’ with the top blade pulling up against compression. At this stage leave the compression where it is only because you say you ran it before so it should be somewhere near. Needle valve as already said about 3 – 31/2 turns. Pull some fuel through by putting your finger over the intake and flicking the prop a couple of times and then flick it several times to bring the fuel through the engine. A squirt of fuel in the exhaust port and then flick a bit harder. If the engine is under compressed it will feel quite ‘easy’ and unresponsive. If it’s over compressed it will feel hard and fairly resistant. If you flood it it may be difficult to get it over compression in which case blow across the exhaust port to clear some of the fuel out of the cylinder. You may need to do this several times – if it keeps flooding close the needle right down, clear the engine of fuel as above then start again with less turns on the needle.

Under compressed – keep flicking but at he same time screw the comp screw in a 1/4 turn at a time – this could quite be a few turns – depends on if the comp has been backed off previously. Continue screwing in until a compressive resistance begins and you are getting near. Don’t expect it to fire and burst into continous running at first – once you establish the settings it should do that. If – When – it fires it may run a few seconds then increase in revs and the stop – that’s too lean and/or slightly undercompressed – open the needle a 1/4 turn and/or increase the comp a tad.

If it runs ‘hard’ – exhaust a bit black – and dies off slowly, revs reducing fairly rapidly thats overcompressed and possibly flooding too so do the opposite.

You don’t need to use anything else other than the fuel to help starting. Despite what I said previously about the fuel probably being okay (which I still think it should be) if the engine simply won’t fire at all then that’s the first thing to suspect. You could be flogging the proverbial so sourcing some fresh fuel should be the next step.

The one thing that I would strongly advise against is using any form of starter motor on a diesel. You could do some serious damage to the internals – starting a diesel is very definitely a ‘feel’ thing.

Terry, I hope I’m not granny teaching with the above. There’s a few ‘armfuls’ of flicking gone into these marvellous little pieces of engineering over the years – knowing what to do is one thing but trying to put it into words is actually quite difficult and another and very different ball game.

Hope this helps as well then

Regards – Ramon

Ramon Wilson.

Ramon Wilson.

but I think David has already made reference to it elsewhere that for some reason it can’t be done.

but I think David has already made reference to it elsewhere that for some reason it can’t be done.

).

).