Jim,

The Velo is buried at the back of the workshop. Haven’t used it in years now. Can’t get rid of it though. It will form part of my estate! It’s a 1957 Venom in nice condition because I rebuilt it twice with 20 years in between. Initially, it was given to me as a basket case. There is no such thing.

The only masochist items are starting it when you first get it. It will break the leg of the neophite in the blink of an eye. You soon learn. The second is the clutch. This is only a problem if you live in a traffic-infested area. It simply wasn’t designed for that. It will jest drag more and more until there is no option but to stop the engine every time you stop the bike. I lived in London then. No problem now, living in a rural area.

The first model engine I built , I silver soldered the crank. It just needed some very careful cleaning up of the fillet. Subsequently, I have used Loctite without problems, except on the Rina. Had exactly the same problem as you. It moved during clean-up. I managed to true it up again and it’s solid now. I think that I was just too impatient. Leave it somewhere warm for a day or two.

As for producing a jpeg, you could always use the “print screen” key on your keyboard, then just paste it into your imaging programme. That will save it as a jpeg or bmp and you can crop it to taste.

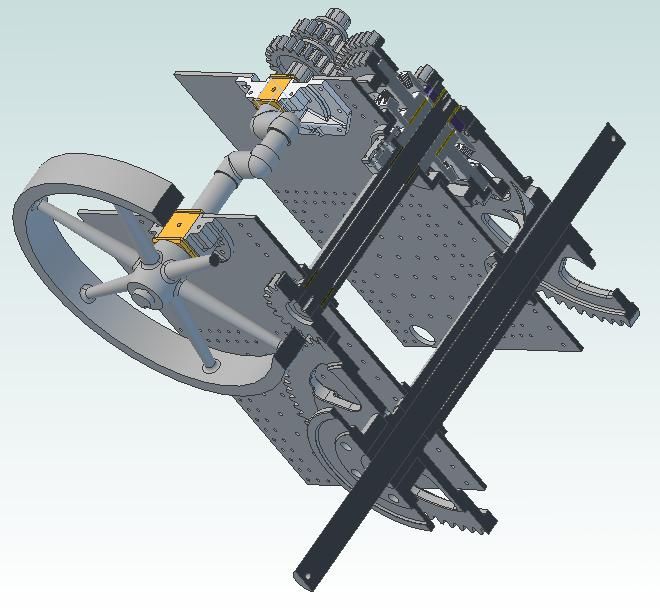

I’ve now got to go and figure out how to position and lock the flywheels onto the crank to give clearance for everything, particularly the governor, to work. I’ve got the keyways, but that’s only half the story.

Regards,

Norman.

Norman Vant.

We’ll have to see how it looks when I get the whole lot assembled.

We’ll have to see how it looks when I get the whole lot assembled.