Needing to replace a motor speed controller seems to be 'not uncommon'. The motor on my Sealey SM2502 stopped working after I tried using a 65mm slitting saw. The motor is OK because it works with 12V DC (Slowly but with plenty of torque.

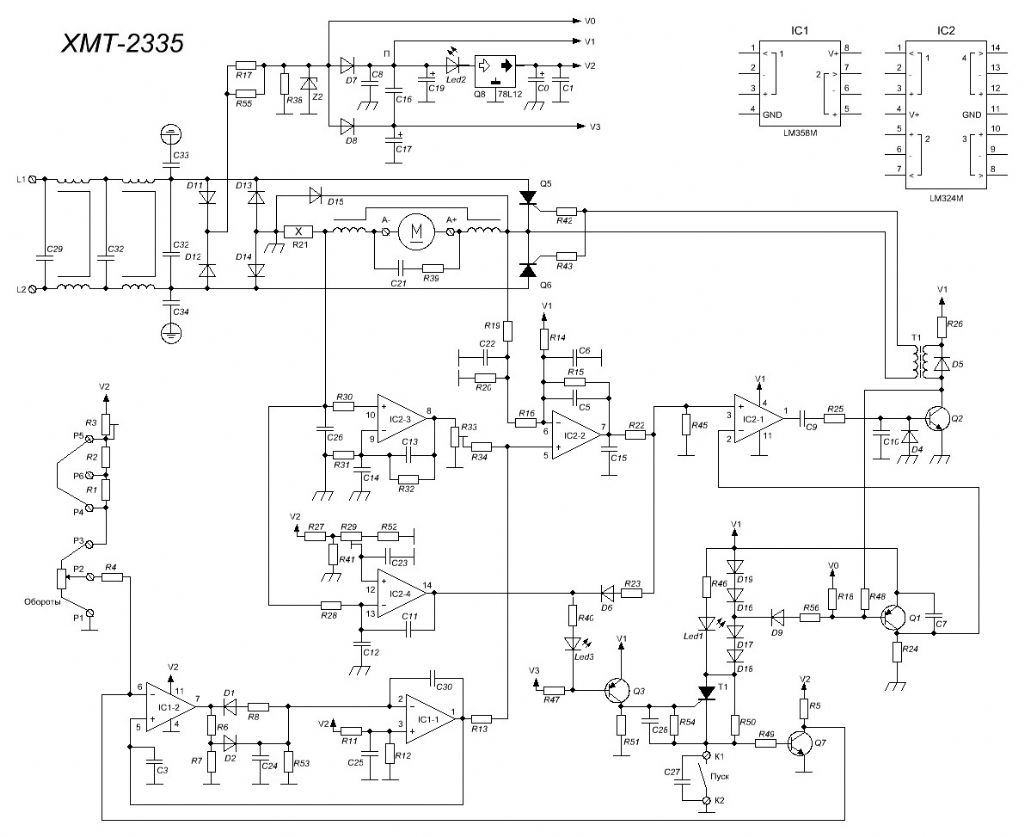

I examined the control board and it has no signs of frying any components. I poked around with my Scope and, apart from the rectification of the input mains supply, it was too hard to trace any fault – apart from no output.

I'm tempted to try a twenty quid controller from eBay, which is ok of a 300W DC brush motor at 230V. I could try replacing the major active devices and the capacitors but it could easily cost me a lot of fruitless effort and the cost of the bits. I can't find a schematic diagram either, which makes it doubly difficult.

I understand that quite a few people have gone down this road, rather than paying a lot of money for a manufacturer's replacement. Are there any lessons to learn? I was wondering if some extra protection in the form of a MCP breaker might do the job as the available cheap boards don't claim to have any (afaics).

What's my chance of success? I really don't want to be without the Mill for longer than necessary.

andrew lyner.