Thank you for this thread! It sent me down the garden to collect my jig and study it in conjunction with these texts.

I have tried using it, and was on the right track but had not realised the subleties. Nor known part of it is missing – the end-stop.

It also seems rather uncertain on the pin that retains the rotating stem in the frame, so it is very easy to have a lot of wobble in the thing. Playing with it here, as I type this, I think this is a matter of skill and a delicate touch with the adjusting-screws, not the result of undue wear.

.

Paul –

I followed the link to Harold Hall's instructions, and have book-marked that.

.

Fowler's Fury –

Your and others' photos have identified mine as a 'Reliance' and it does have what seems a figure '1' hidden shyly away in the base recess.

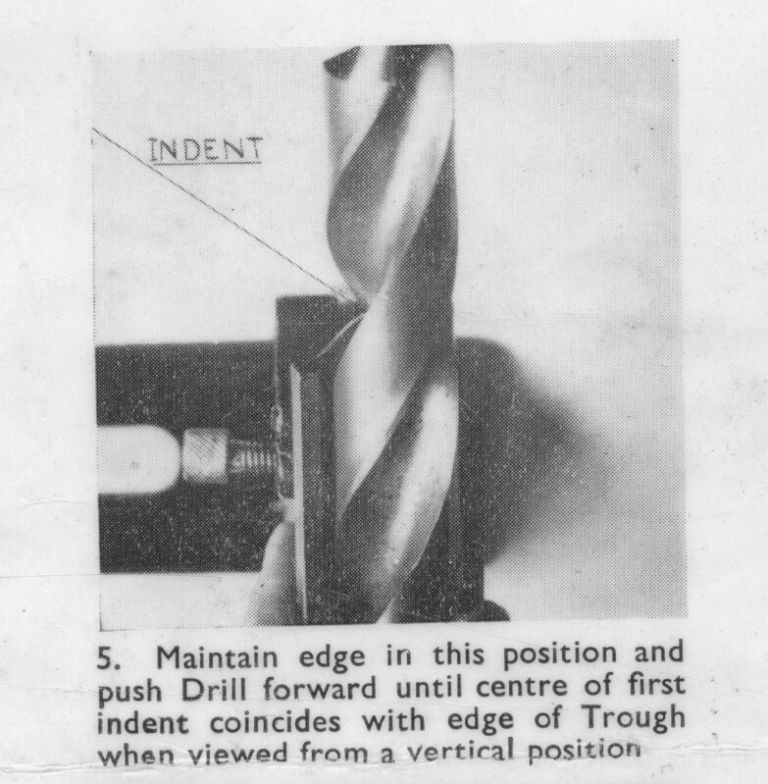

It lacks the drill end-stop you show; so your picture answers my puzzle about how to turn the drill round to the other face while keeping the length constant.

It would be simple enough to make a replacement, especially if the triangular part is round rod instead. Square bar would be appropriate – turn a spigot to fit into its holder part; pin and glue.

(A triangular bar would be easy to mill using a dividing-head or Vee-block to give the 90º working angle. Since he is cited above, see Harold Hall's book on grinding, to sharpen the cutter!)

Robert Dodds.