Thanks everyone for their inputs.

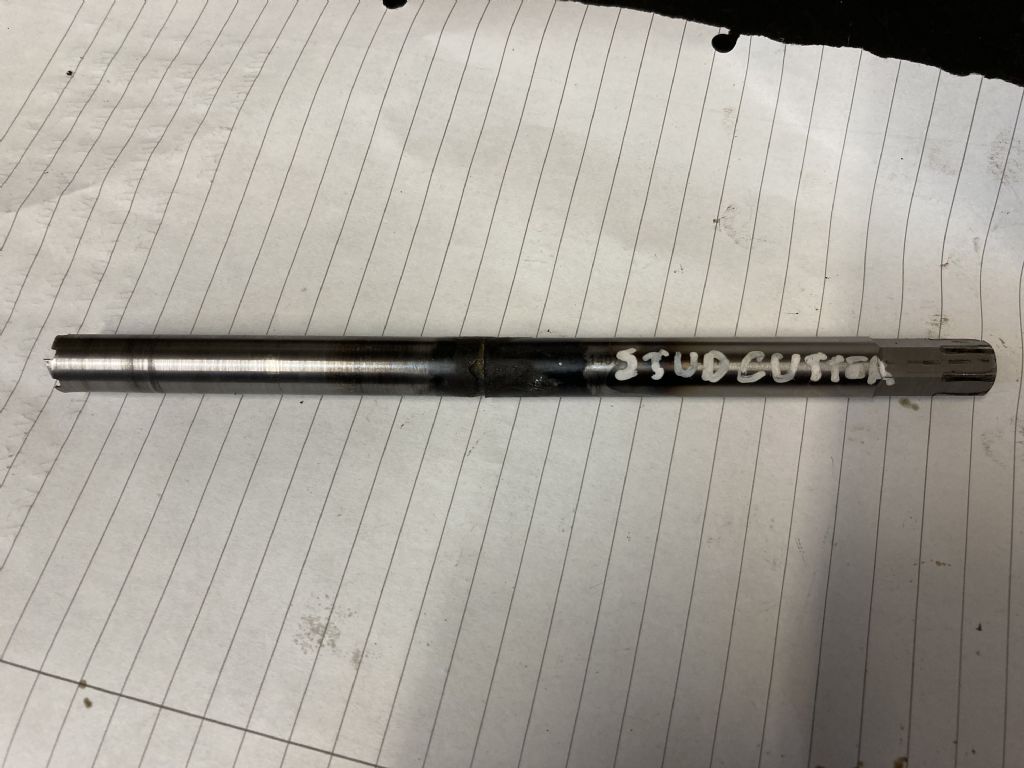

Just to clarify the studs are sliding fits through the head being screwed into the block at their lower portion and they hold the head down by way of nuts bearing down on the external upper head face. There is no threading involved (other than the nuts which remove with no problem and the lower end of the studs which thread into the block – and hopefully stay there! )

Old Mart – the studs are 7/16th dia (~11mm) and the nominal clearance hole in the head is just slightly over 12mm. I'd forgotten about Sykes Pickavant. Can you tell me what the o/d is on the 7/16th tube saw please?

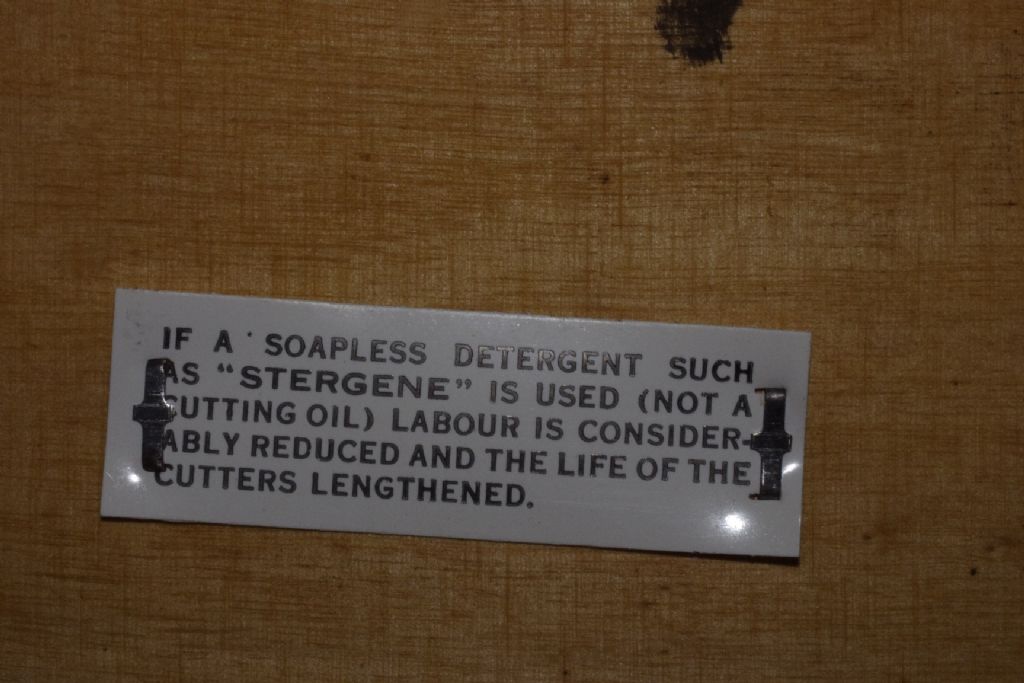

Hopper – we did look at a Rotabroach and we purchased their 12mm o/d broach but the internal dia was just 6 mm! I considered grinding it out to 11mm but decided there would not be much left as the flutes would disappear leaving just 'legs' – the tube saw needs to be about 4 1/2" long to get through the head.so any Rotabroach would need mounting on an extension tube.

J Hancock – we do not want to remove the studs or damage them as they are hard to replace, both physically (extracting them from the block is precarious ) and purchase wise ( £11.50 per stud ).

Jeff Dayman – novel idea! Again I had considered EDM and water cutting but as there are 14 studs per bank we would have to make a multi tool to attack all 14 studs in one go. Will an EDM system work solely on the front end of the tool and not 'short out' as the sleeve goes deeper between stud and head?

Again thanks to all for responding to my question – all food for further thought.

Martin

David George – That sounds like a promising avenue to investigate. glass diamond hole cutter! Have you got a link please to a manufacturer / supplier?

Neil Wyatt.

Neil Wyatt.