Posted by Nicholas Wheeler 1 on 29/05/2022 19:01:08:

In Fusion Design in place is known as Top Down Design.

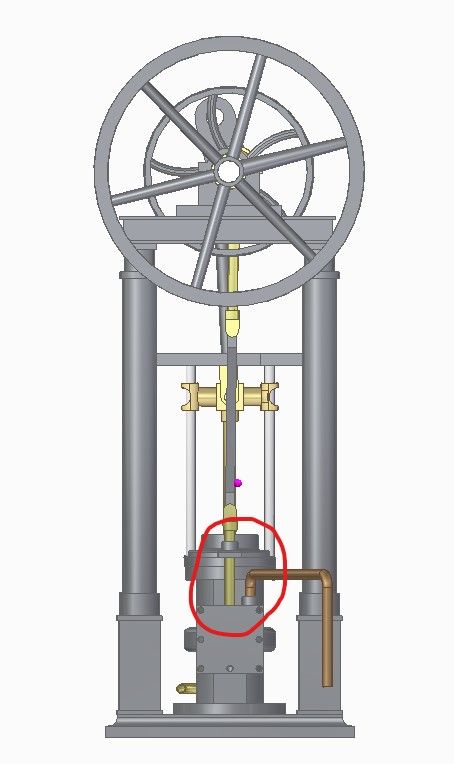

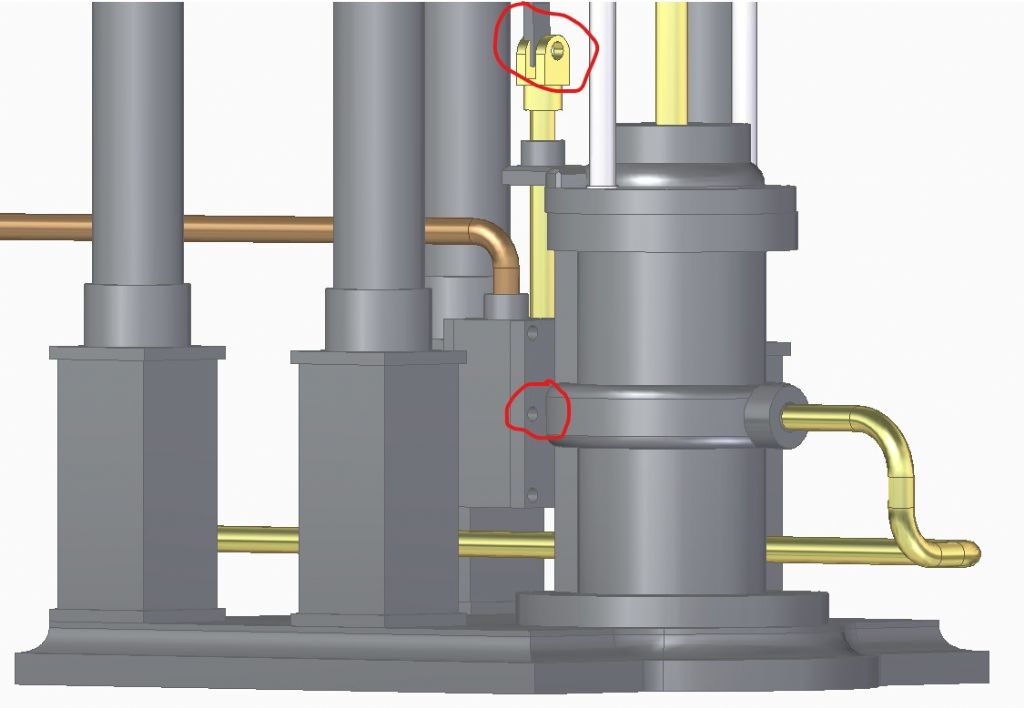

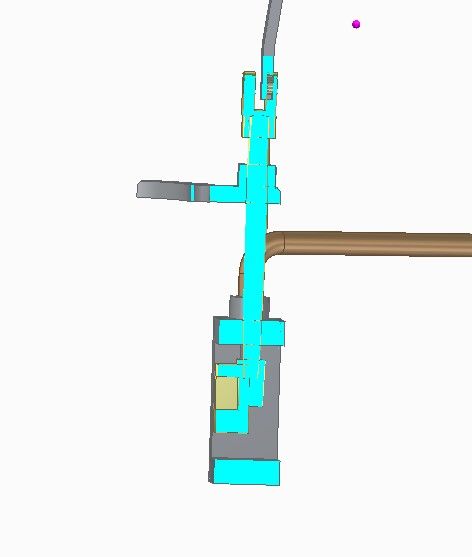

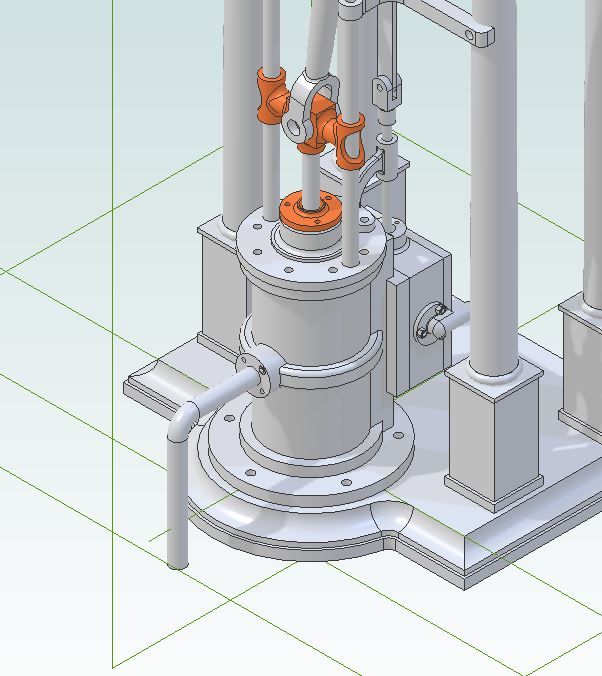

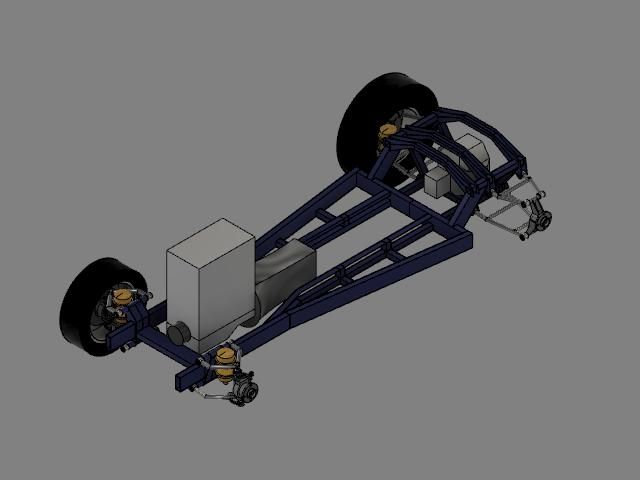

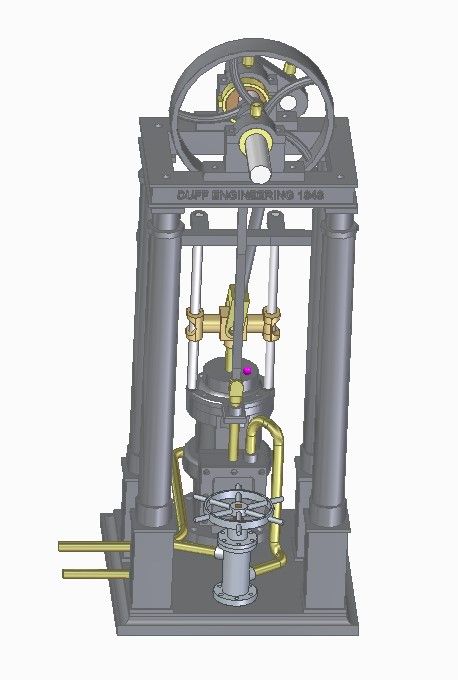

Each discrete part(or component) is created in the same file, so your engine, locomotive, chassis, whatever is a complete, but virtual, thing. This chassis, complete with fully articulated suspension is an example:

I see no reason to make separate components to import into other files, even if the free version didn't make that slightly trickier.

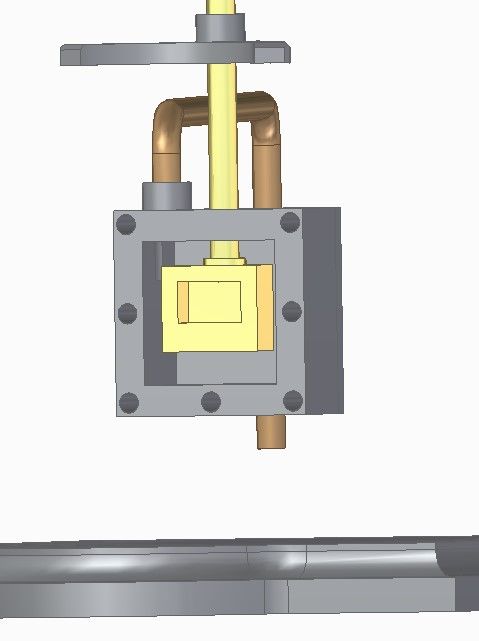

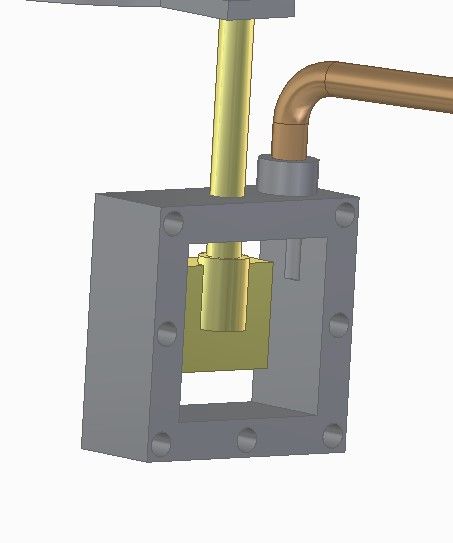

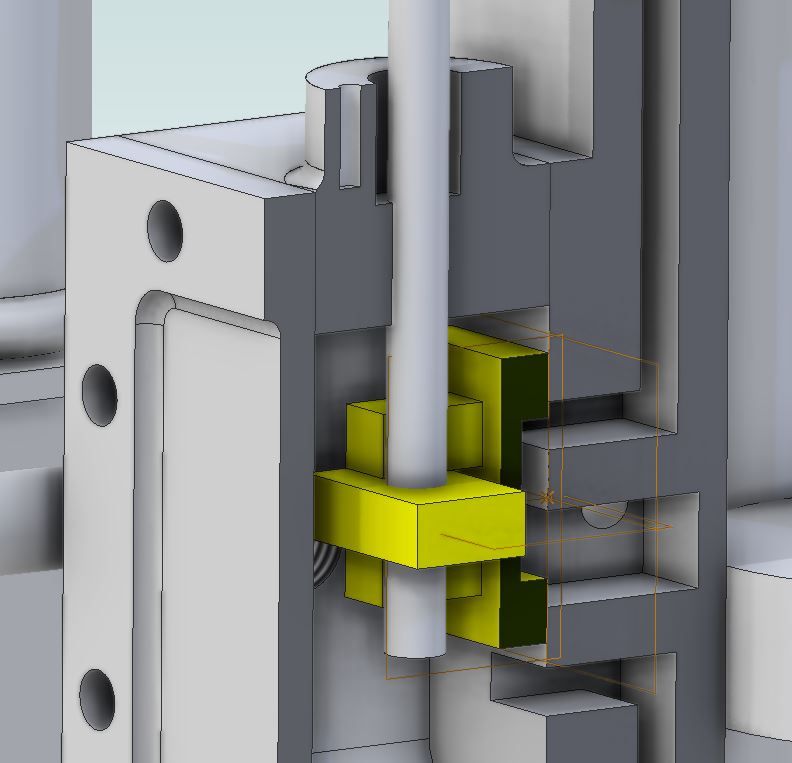

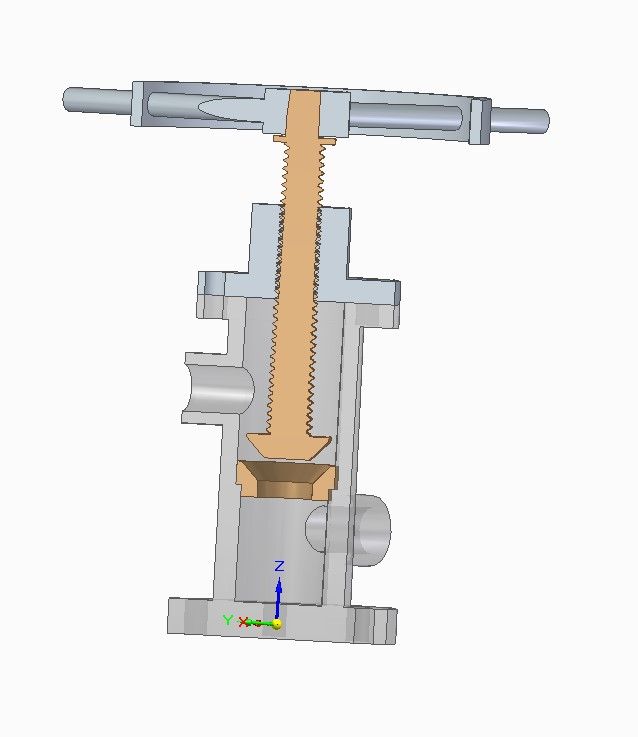

It is much easier to create each new part in the place it's going to fit, referencing the relevant geometry, like a piston in a bore as a simple example. Or the other way around, as you can create the crankshaft, rods, pistons and valve mechanisms first, then build the block/heads etc around them.

I read about Top-Down design early on, and studied some examples, but I could never get a good enough feel for it to actually be able to use it in a predictable fashion.

No doubt it has great merit in the hands of someone skilled enough to know how to use it.

One thing that I do that is perhaps similar is that I open the model for a part that is to be mated, and capture the mating face sketch, and then paste the sketch into a new part, and begin the new part with the known geometry.

Thus when I go to mate the two parts, I know they will fit because they share the same base sketch.

.

Edited By PatJ on 29/05/2022 19:58:50

SillyOldDuffer.