Posted by Rob Walker on 26/06/2023 22:26:29:

…

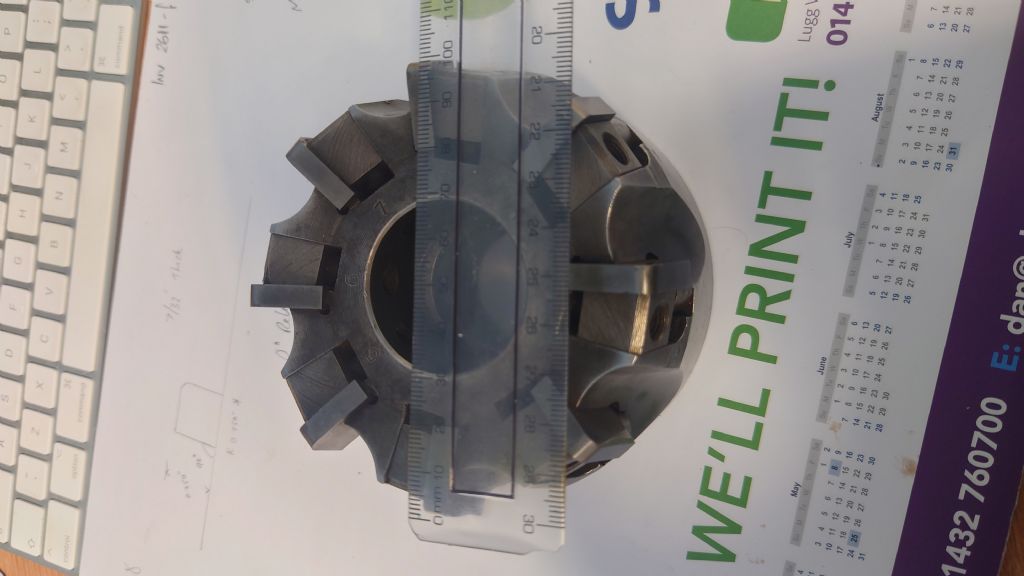

Machine capable of big stuff and just wanted to have the few larger cutters up to grade for Justin (case)👍

Thanks for the leads, will phone around 👍

Can you let us know quotes?

It's cost versus value question, where the answer depends on circumstances.

My workshop has a basic vertical hobby mill. It's mostly used for light detail work, not hogging metal. Not having a horizontal mill means paying to sharpen horizontal cutters has no value to me. Might be worth having a big helical cutter sharpened for a special job, but I rarely use them. Those I bought with the mill 'justin case', are still sharp, and a few have never been used. This is why experienced machinists don't recommend buying sets – there's a risk of wasting money on tools that never get used.

Same problem with buying second-hand and finding it comes with a box full of random cutters, many blunt. Financially, there is no point in having them sharpened unless they're going to be used.

There's an argument in favour of owning tools 'just in case'. It's time saved when a new job suddenly requires a particular tool and there's a painful delay whilst one is ordered and delivered. Sod's Law guarantees that urgently needed tools are always out-of-stock.

Trouble with buying 'just in case' is it costs a fortune, takes up space, unusual tools are hard to find in deep storage 10 years later, and grieving relatives will probably dump the whole lot into a skip when the time comes.

I guess most Model Engineer's target our tool-spending on things that are definitely needed rather than stocking up on the off chance. Bargains are always welcome, but some thought goes into 'is this worth it?'

The value of sharpening cutters is strongly influenced by what I do with them – light detail work at gentlemanly hobby rates! Cutters last a long time in my workshop because I don't cut a lot of metal quickly. Others work their machines much harder, and value of sharpening becomes more evident. Professional workshops have to work quickly and efficiently, time is money. Amateurs are between two extremes. Some collect tools and never use them! Others are as busy as a busy commercial operation. Most are in the middle, and I suspect tool sharpening is a low priority.

Not resharpening is something of an industry trend. In the good old days most machine shops resharpened in-house. These days that's unlikely because third-party specialists do the same job cheaper and better. In the smaller sizes CNC cutters are often single-use, replaced when worn. They're recycled rather than resharpened. I think this is partly economics and partly because resharpening alters cutter size, bad news when a machine auto-changer expects cutters to be standard sizes.

I'm not sure resharpening is high value to most Model Engineers. I've been a cynic since reading the accusation in an old ME magazine that almost every workshop in the land had an unfinished Stent and Quorn under the bench! In my case, most of the time, it's easier to buy new. I'd think differently if my workshop took a week to blunt a big cutter costing £100 plus that could be resharpened in a week for £20. Then I buy 4 of them, so one was always cutting, with one out being resharpened, and two in reserve. In this scenario the initial investment is £400, plus £1040 per year on sharpening. Assuming each cutter can be sharpened 5 times, I also buy one new cutter per month (£1200). But I'm not in that game – my needs are met by occasional orders for a few new cutters.

Dave

Rob Walker.

and a couple of larger slot cutters for the horizontal setup only, the smaller cutters if needed are cheap enough. there are a few larger 2/3/4 flute end mill cutters in sizes that are so expensive I would never really buy them new unless there was a very specific (and financially viable) reason! some are easily £100+ each.

and a couple of larger slot cutters for the horizontal setup only, the smaller cutters if needed are cheap enough. there are a few larger 2/3/4 flute end mill cutters in sizes that are so expensive I would never really buy them new unless there was a very specific (and financially viable) reason! some are easily £100+ each.