Hi folks

Hi folks

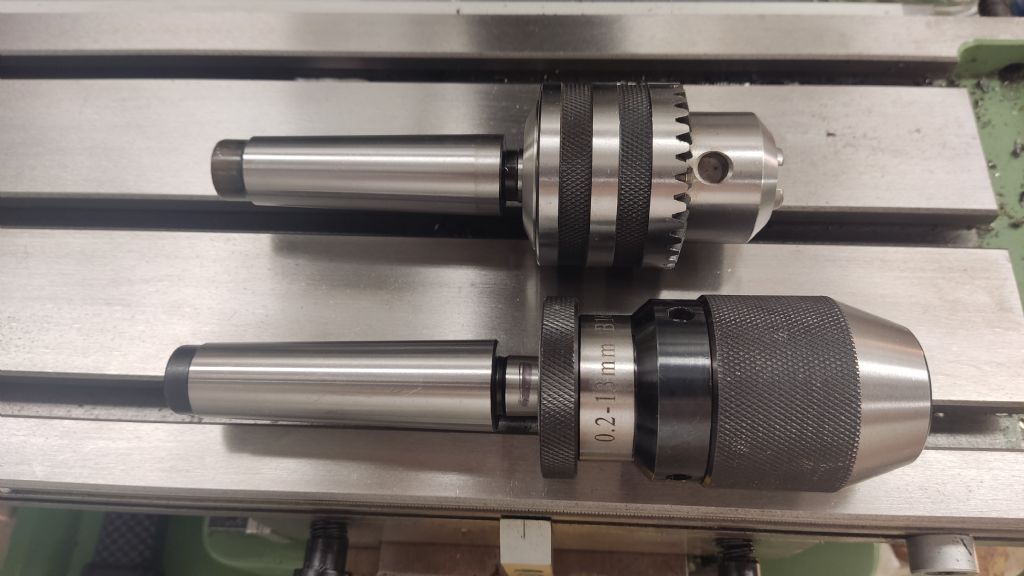

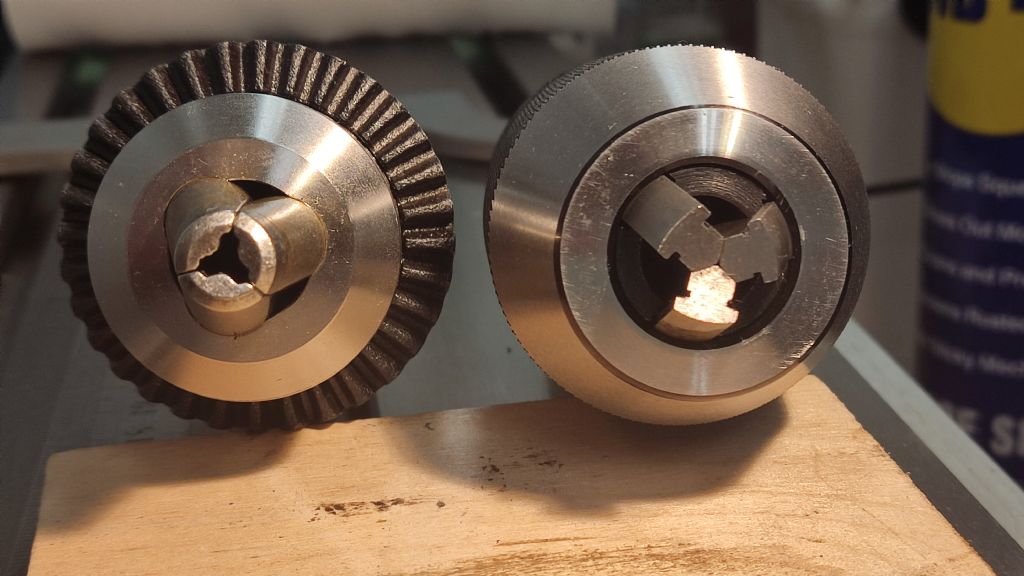

I have uploaded some pictures. My first impression that the taper was an incorrect fit was because it protruded so much more than the original chuck.

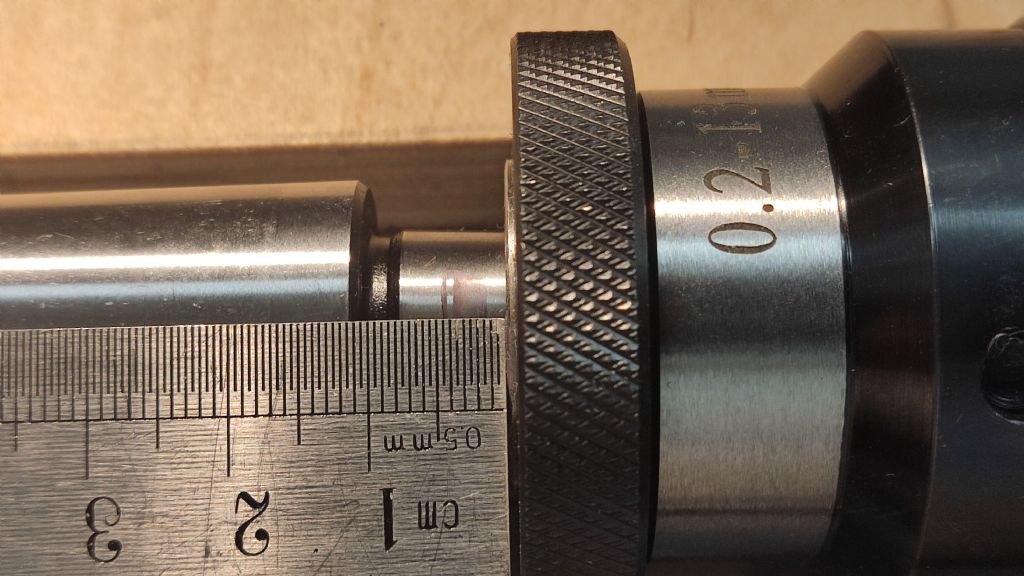

So after all the discussion I marked the male taper 25mm up, ignoring the chamfer. This was a mistake, the chamfer is part of the specified dimension, it should have been 24mm so take 1mm off your measurements below. I fitted the chuck by hand and there was a good gap between the mark and the top of the chuck.

I fitted the assembly and forced it together with the mill quill which I videoed. I don't think it got much deeper so maybe a squeeze in the vice or a tap with a hammer, suitably protected, is required.

Lastly for the night here is a simple picture that shows that I needed something to hold small drills.

As Jason says there is a lot of luck on those last few microns of any set up so I will have another try another day. then I will update the video or do a part 2. I videoed the runout of the chuck as jammed on and it was 0.055mm so a little worse than before and worth playing with.

There is also the drilling test to look forward to.

Roger Best.