Hi Roger,

Ian will review your email when he comes in, and he will get back to you.

Just reading this thread (without site of your email), I would suggest that both the chuck and arbor are fine, regardless of expectation for the price in comparison with expensive Rohm or Albrecht chucks.

We sell both products on a daily basis… mainly to industrial users, as well as certain blue chip trade re-sellers, without complaint. We know the factory from where we have purchased the chucks from, and we know the factory from where we have purchased the arbors from. Apart from the odd Friday afternoon product, we are comfortable with the consistency of our supply. However, I will let Ian review your email and get back to you.

With regard to getting into detailed discussion on the subject on here, this is all I will say:

About ten years ago, my team, John Stevenson (who passed away in 2017) and I spent over a year checking keyless chucks from 5 different factories. There are three grades of Chinese keyless chucks. There is high precision – used for CNC (P), Heavy Duty (H), and General (G).

Our findings were as follows:

- Some factories sampling fialed to reach any of the specifications they specified.

- Some factories only offered us G grade.

- Two factories offered us all three grades, and we chose to test the P and H grades only.

- P grade failed all around on the SIEG machines on which we tested them, and we found that the run-out was worse that the H grade.

- We even had a batch of P grade which we returned to the factory as they failed on run-out.

- Tests on our machines included using silvers steel, known turned reference stock, reference stock supplied by the keyless factory for testing, 6mm and 10mm. These were checked at 15mm and 25mm away from where they were held in the chuck. These were checked by hand rotation, as well as at low speed. The chucks were loosened, the stock was moved by hand inside the chuck, so that the jaws could be tightened in a different position. Then the chucks were checked again for run-out. These checks were done on three different machines.

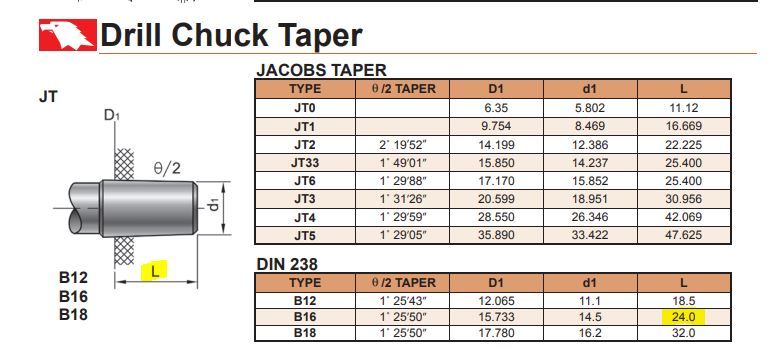

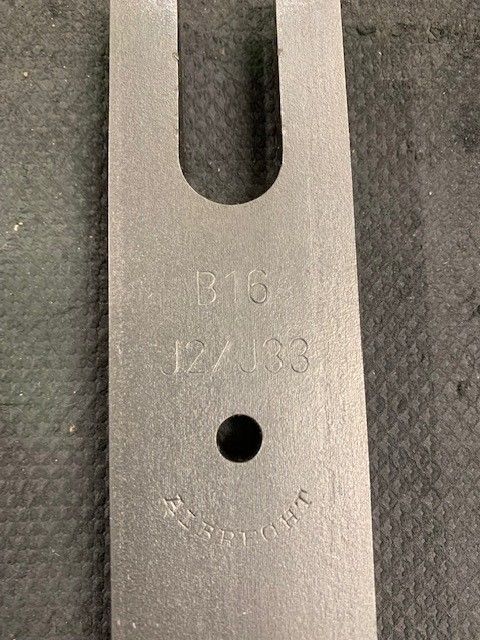

- Results were different on every machine. Variable factors taken into consideration… spindle run-out, distance from end of spindle to the point at which the round stock was checked, arbor fit to the spindle, JT/B taper fit to the keyless chuck, and one or two other elements which I may have forgotten.

- Results on the keyless chuck factories test rigs were also different to the results we were finding when fitted to the SIEG, as well as Johns and certain other peoples machines.

- An average was taken, and we finally settled on the factory we use use, with the H grade. It happens to be the most expensive, but at the same time the smallest factory (in terms of production run), from the five factories we tested.

- It would still be wrong for me to set a reference for comparison against Rohm chuck because:

- there are too many variables involved as mentioned above

- we do not buy the arbor with chuck pre-assembled at the factory

- our results differ from rests on the keyless chuck factories test rig

We are not prepared to purchase and supply chucks pre-assembled with arbors from ANY factory. Reasons are:

a. non of the factories we tested, including the keyless chuck factory we use make their own arbor.

b. the quality/grade of the material used for the arbor in the pre-assembled units can be variable.

c. the accuracy of the material used for the arbor in the pre-assembled units can be variable.

d. the cost of the arbor from the factory where we buy the arbor is more expensive than the cost of the arbor supplied by the keyless chuck factory, and we cannot be certain of the source.

d. we do not want to keep pre-assembled stock of products…. as this would mean we would have to keep more stock.

We have purchased and supplied the same consistent quality of arbors from one specified factory for over 20 years. The return rate is next to zero.

Chuck removal wedges: For jacob style chucks – they are slim wedges. Albrecht wedges are very thick.. I am guessing because some of their chucks may fit with a bigger gap… but I cannot say for sure.

If the tapers have been mated correctly – i.e. male and female cleaned out to remove the transit oil, and press fit correctly/hard enough (and not by hand only), the resulting run-out is considered to be reasonable for the chucks and arbors we sell. Again, it would be wrong for me to get into results of the tests, as well as any detailed discussion on this over this forum, due to all the assembly variables involved.

Also a note: depending on type of use, the keyless chucks can also tighten and jam.. including Rohm/Albrecht or any other keyless chucks. If mail/female tapers were not cleaned before assembly, they will mark the mating tapers and change accuracy. Using hammers to dismount chucks from tapers can also result in the same problem.

This is a matter for Roger to discuss with Ian and conclude.

Ketan at ARC.

Roger Best.